An opposed energy-saving stone crusher and ore crushing method

A stone crusher and opposite technology, applied in grain processing and other directions, can solve the problems of high energy consumption and low use efficiency, and achieve the effect of reducing energy consumption and improving stone crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

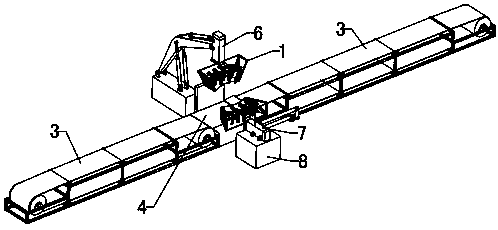

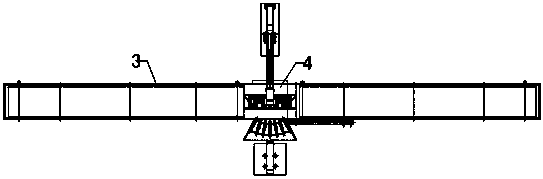

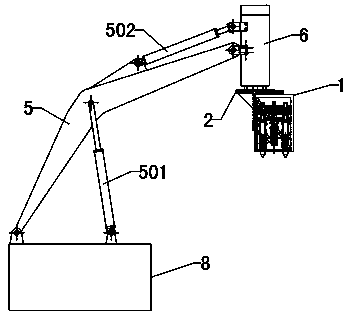

[0031] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0032] Refer to attached Figure 1~2 : An opposed energy-saving stone crusher, comprising a conveyor 3, two groups of gravel clamping and impacting devices 1 are arranged above the conveyor 3, and one side of the gravel clamping and impacting device 1 is provided with a push-out mechanism to drive its overall movement. Mechanism; two groups of gravel clamping and impacting devices 1 are arranged vertically to each other, one group of gravel clamping and impacting devices 1 is vertically arranged, and the other group of gravel clamping and impacting devices 1 is arranged horizontally. The gravel clamping and impacting device 1 is provided with a plurality of radially arranged vibrating punches 102 , and each vibrating punch 102 is provided with an independently controlled electromagnetic drive device 101 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com