Continuous refurbishment painting system for road guardrails

A highway guardrail and painting technology, applied in spray booths, spraying devices, etc., can solve problems such as troublesome replacement, deformation of highway guardrails, time-consuming and labor-intensive problems, and achieve the effects of shortening maintenance time, reliable working principle, and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

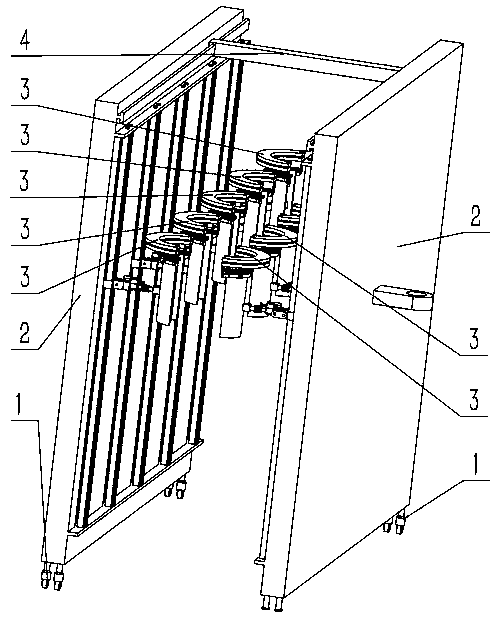

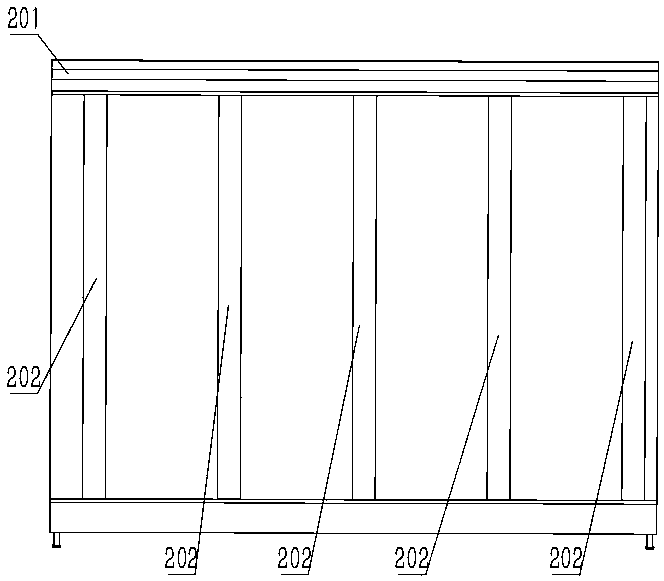

[0026] Such as Figure 1 to Figure 11 The continuous refurbishment and painting system for highway guardrails shown includes universal wheels 1, walking bracket 2, mobile module 3, stabilizing frame 4, high-temperature drying sheet 5, paint spraying tube 6, high-pressure water washing head 7, and polishing rod 8 , Grinding head 9, cover plate 10, belt 11, pulley 12.

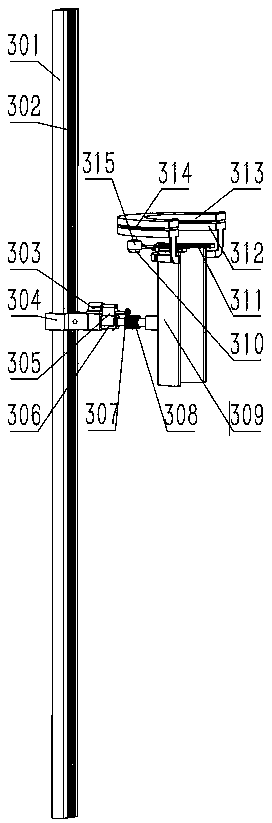

[0027] The mobile module 3 includes a rack frame 301, the rack frame 301 is provided with a rack frame chute 30101, the rack frame 301 is fixedly equipped with a rack 302, the rack frame 301 is slidably installed with a climbing motor seat 304, and the climbing motor seat Two lifting balls 316 are arranged at the rear of the 304, and the lifting balls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com