Dust-proof cement unpacker

An unpacking and dust-proof technology, which is applied in the field of construction machinery and equipment, can solve the problems of serious physical injuries of construction workers, achieve the effects of protecting workers' health, avoiding dust, and strong practicability

Active Publication Date: 2019-10-01

江苏博创升降机械有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is that in the prior art, the construction site can only manually unpack the cement, which causes great harm to the construction workers.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

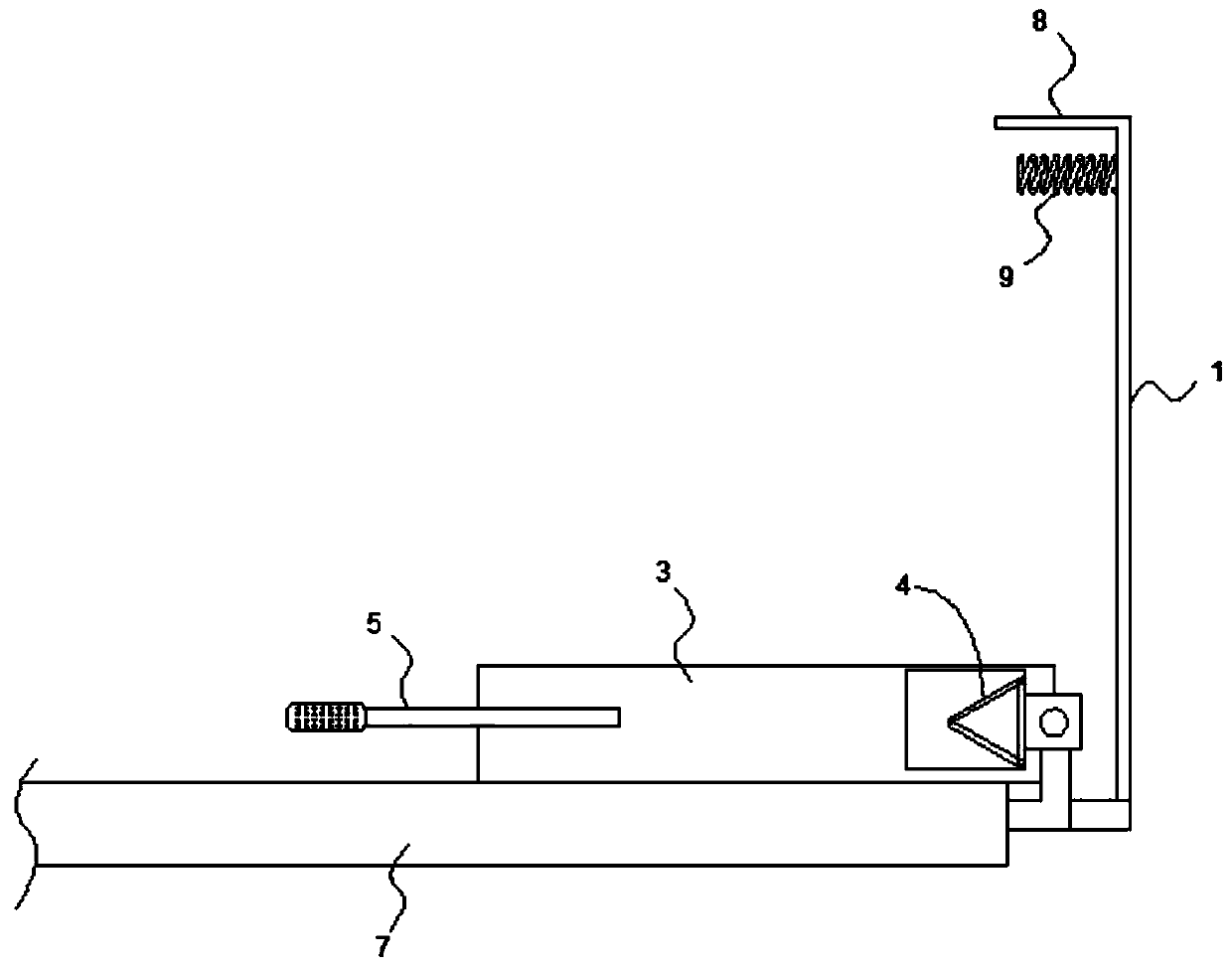

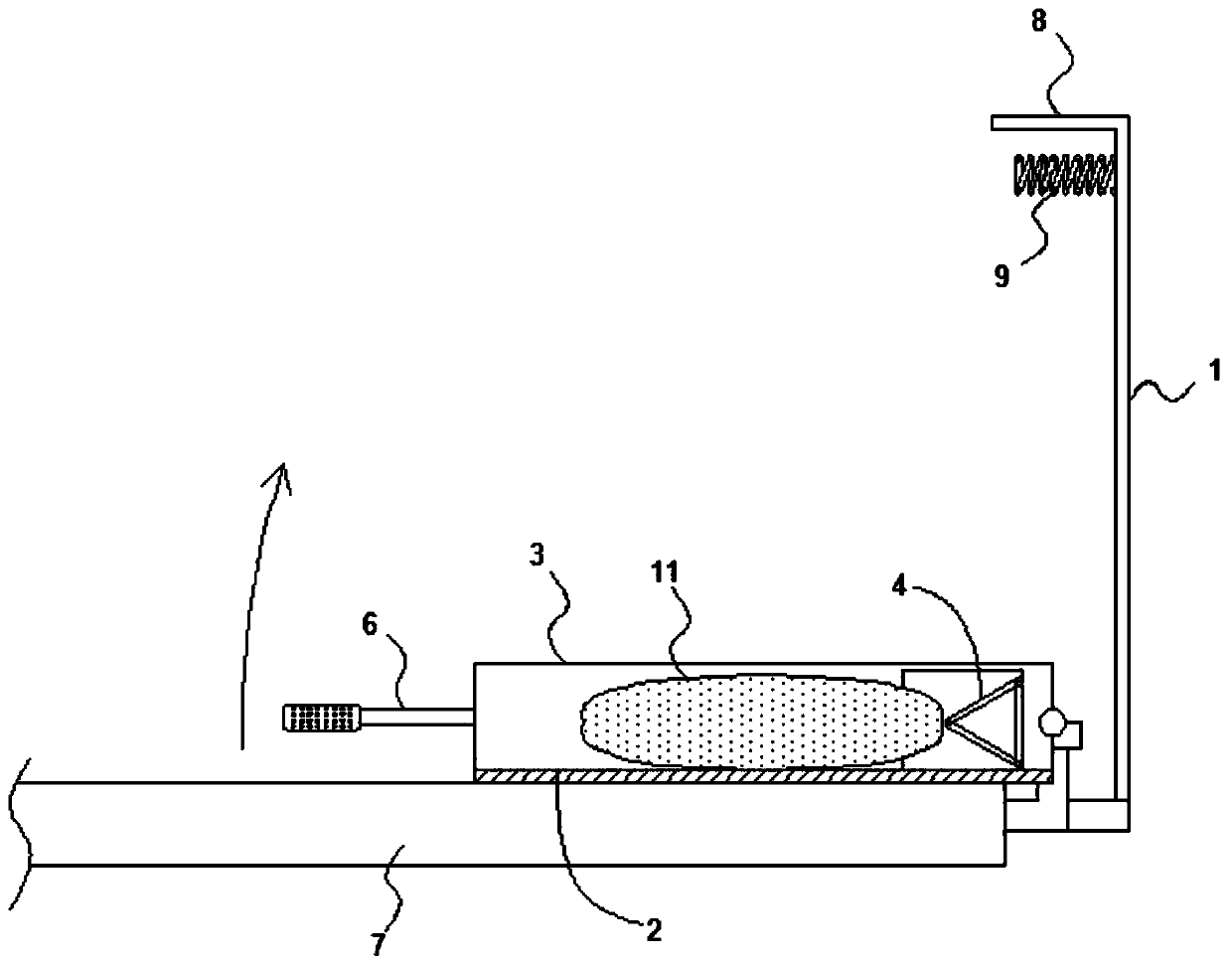

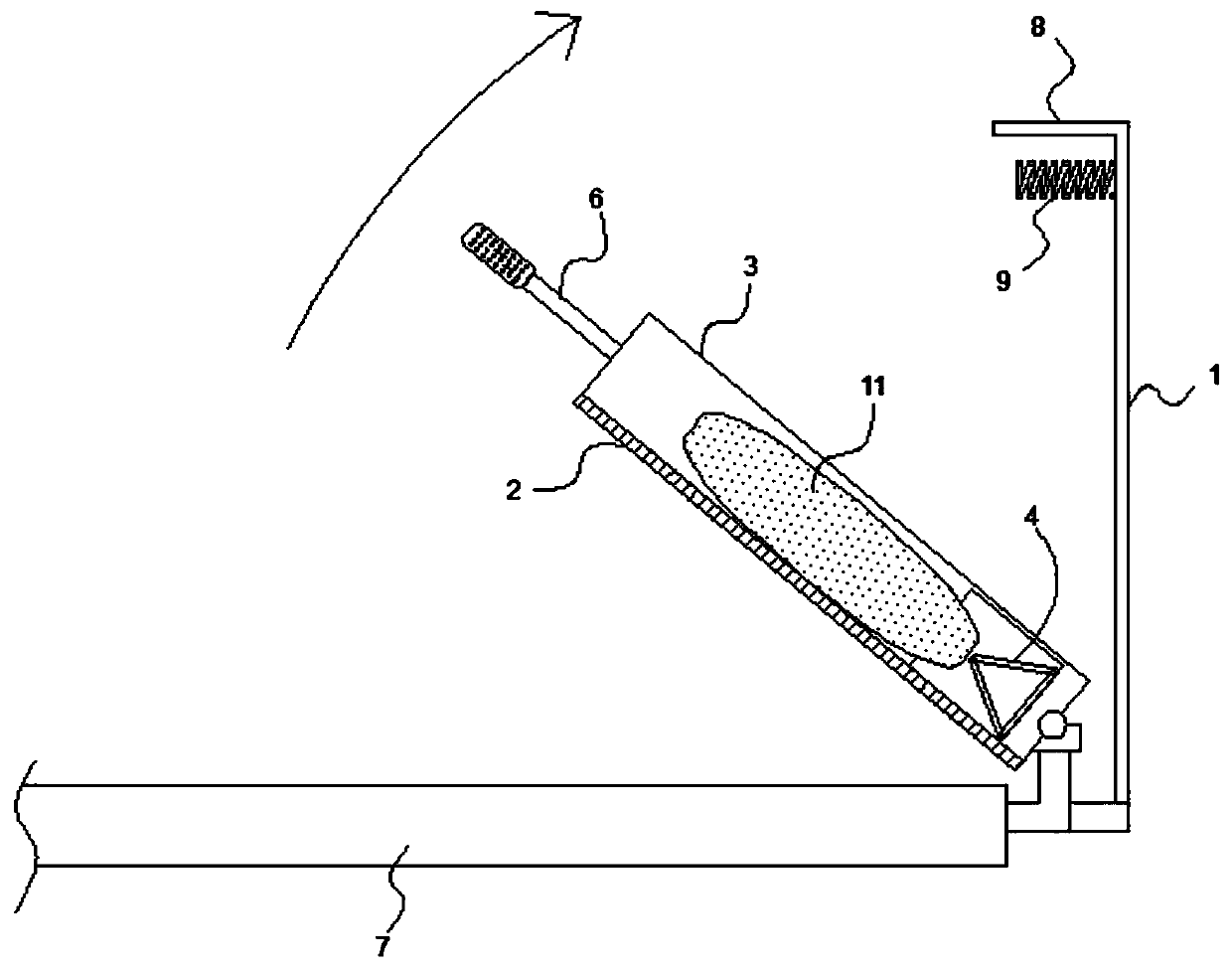

The invention discloses a dustproof cement bale breaker comprising a front baffle, a baseplate, side plates, a cutter, a first handle and a second handle; the front baffle is fixedly installed on theedge of a platform vertically; a group of opposite sides of the baseplate are each provided with one side plate so that a concave part is formed, and the bottom of the concave part is hinged to the edge of the platform; after the concave part is erected, a box body of which the top and the bottom are open is formed by the concave part and the front baffle; the bottoms of the side plates are provided with openings, and the cutter is transversely arranged in the openings of the two side plates; the cutting edge of the cutter is upward; the first handle and the second handle are separately installed on the outside surfaces of the two side plates, and the first handle is fixedly connected to the side plates; the middle part of the second handle is hinged to the side plates; and the tail part of the second handle is hinged to one end of the cutter. The dustproof cement bale breaker disclosed by the invention is simple in structure and high in practicality; after a worker uses the dustproofcement bale breaker, cement flying dust generated by directly opening a cement bag can be avoided, and the health of the worker is protected.

Description

technical field The invention relates to the field of construction machinery and equipment, in particular to a dust-proof cement unpacking device. Background technique A large amount of concrete is used in the daily construction of the construction site, and the concrete is generally formed by the construction workers on the construction site by mixing cement, sand and water. Although various types of mixers are basically used to process concrete in the prior art, the operation of adding cement to the mixer is still done manually due to poor conditions. The basic method of processing concrete on the construction site is: (1) build a platform and stairs around the mixer; (2) workers carry the cement package to the platform through the stairs; (3) remove the cement package, pour cement powder into the mixer on the platform feeding port. Since the cement is in powder form, the operation of unpacking cement and pouring the cement can easily raise a large amount of cement dust...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B69/00

Inventor 胡军赵静

Owner 江苏博创升降机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com