Stirring rod hanging structure for electronic display glass platinum channels

A platinum channel and electronic display technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems affecting steel components, large swing of the lower end of the stirring rod, poor lubrication of the stirring rod, etc., and achieve high temperature protection Infringement, ease of use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

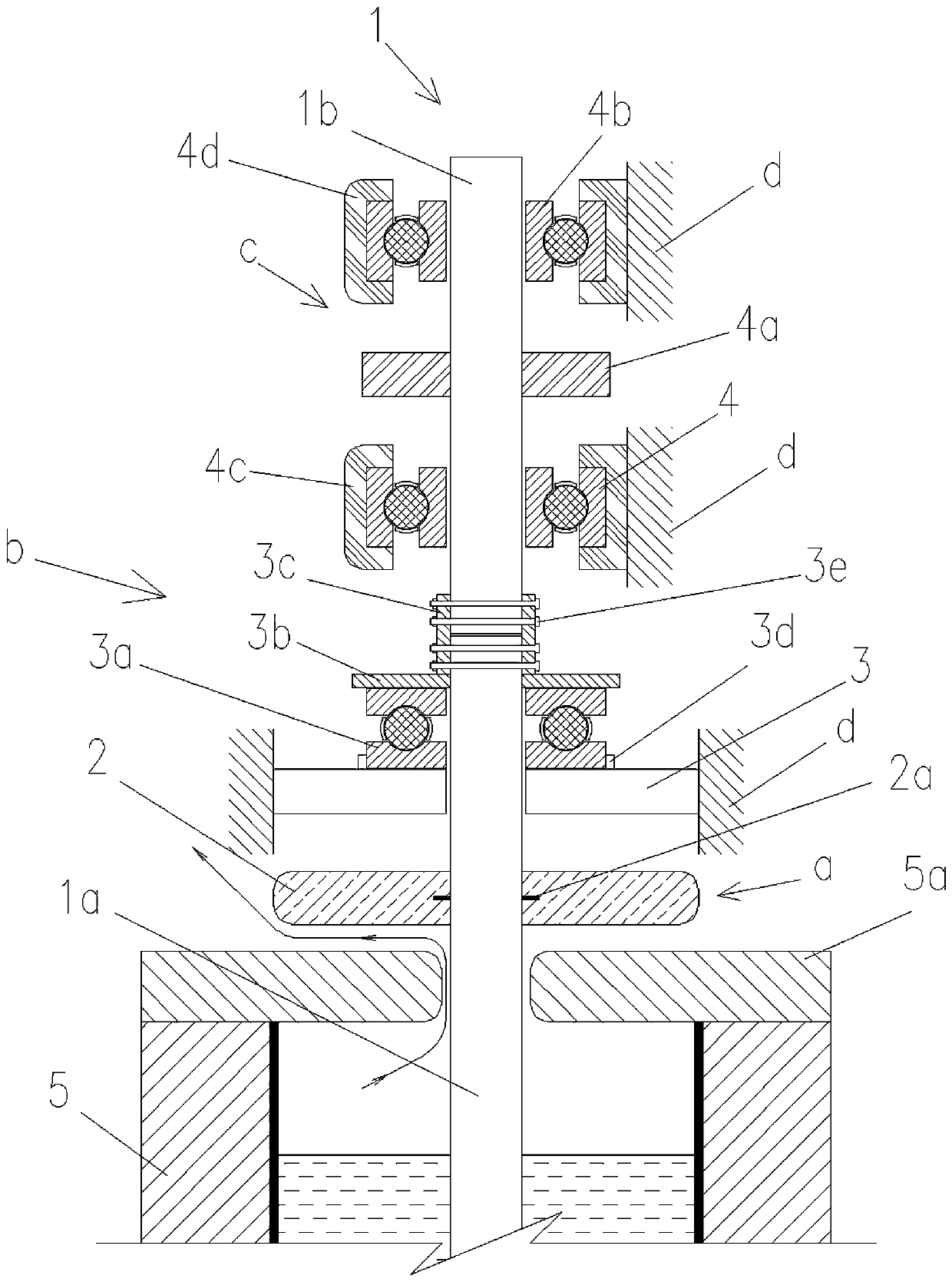

[0015] Such as figure 1 As shown, a stirring rod suspension structure for electronically displaying a glass platinum channel, it includes a stirring rod 1, and the stirring rod 1 is composed of a coaxially arranged platinum rod 1a and a steel rod 1b, thereby effectively reducing the production and The cost.

[0016] The lower part of the platinum rod 1a extends into the mixing tank 5, and the upper part of the platinum rod 1a is located above the cover plate 5a of the mixing tank. On the shaft of the stirring rod 1, a flame shielding mechanism a and a suspension mechanism are sequentially arranged from bottom to top. b and the stabilizing mechanism c, the driving wheel 4a is sheathed on the stirring rod 1 in the middle of the stabilizing mechanism, and the suspension mechanism b and the stabilizing mechanism c are correspondingly connected to the frame through the joint d.

[0017] The flame shielding mechanism a includes a circular flame shielding plate 2 sleeved on the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com