Double-face flange pipeline connection method

A connection method and flange technology, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problem of high construction cost of large-diameter pipeline connection, difficult pipeline calibration process, and low pipeline alignment accuracy. problems, to achieve the effect of wide connection applicability, reduced labor intensity, and convenient construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

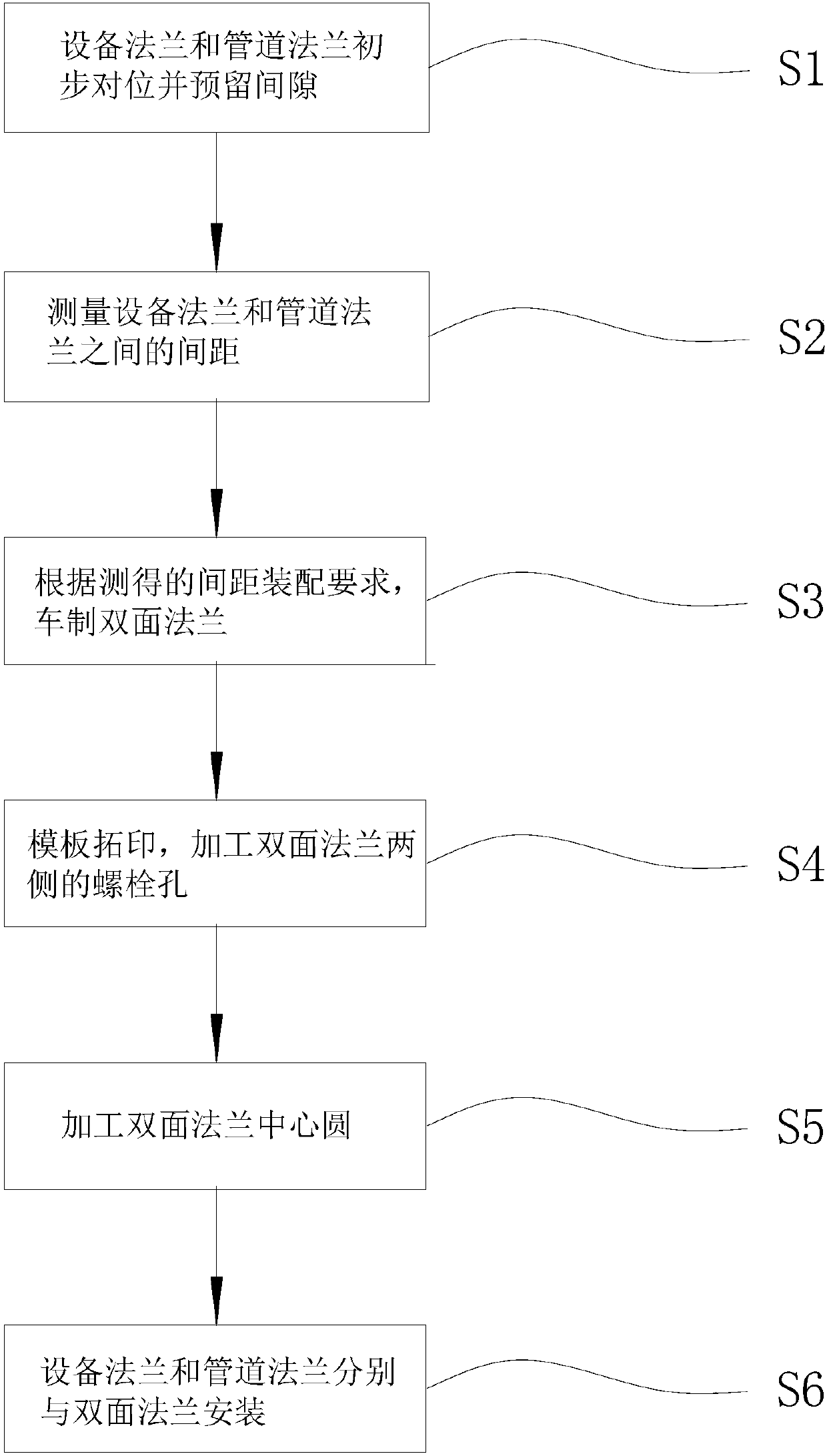

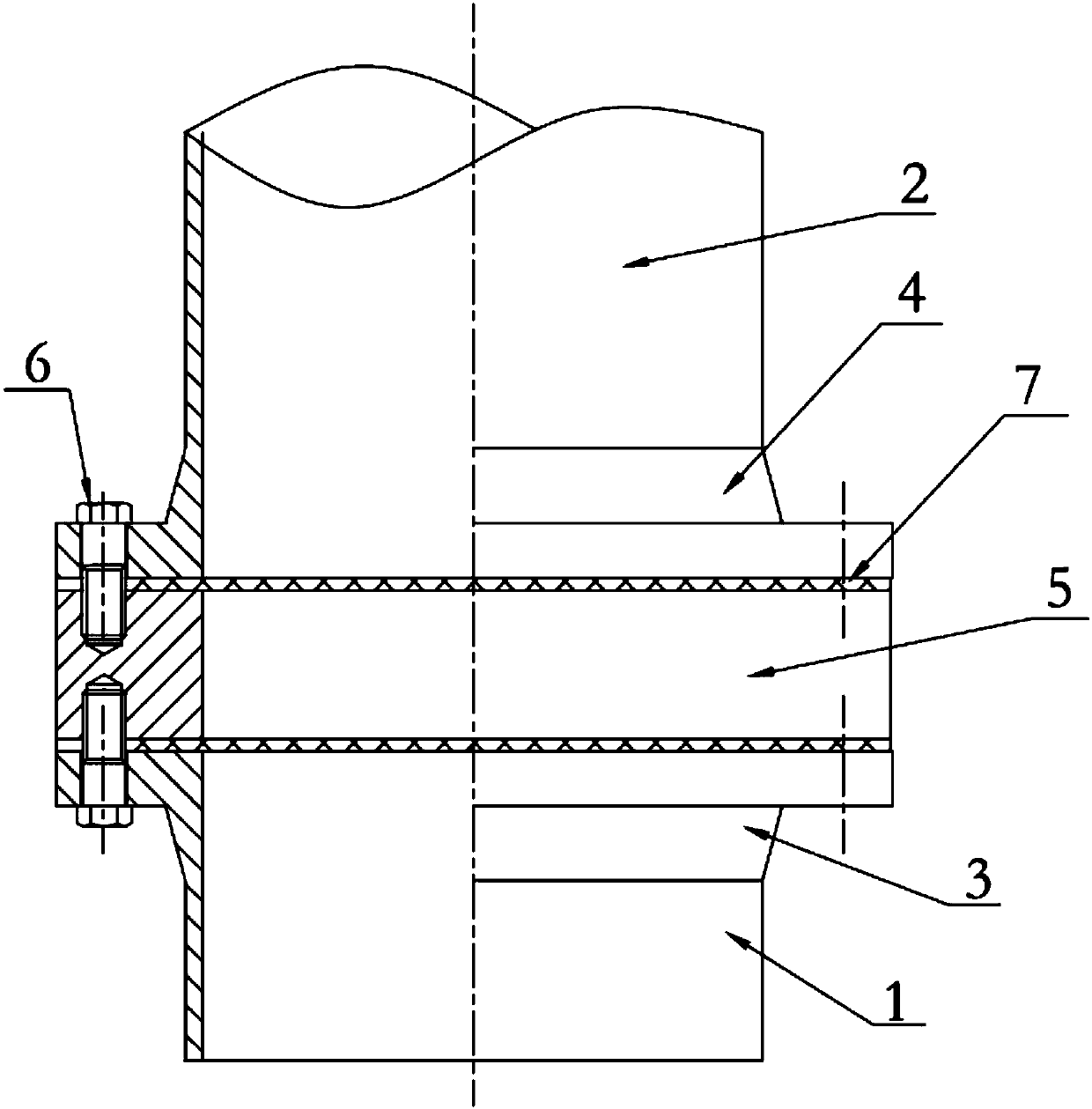

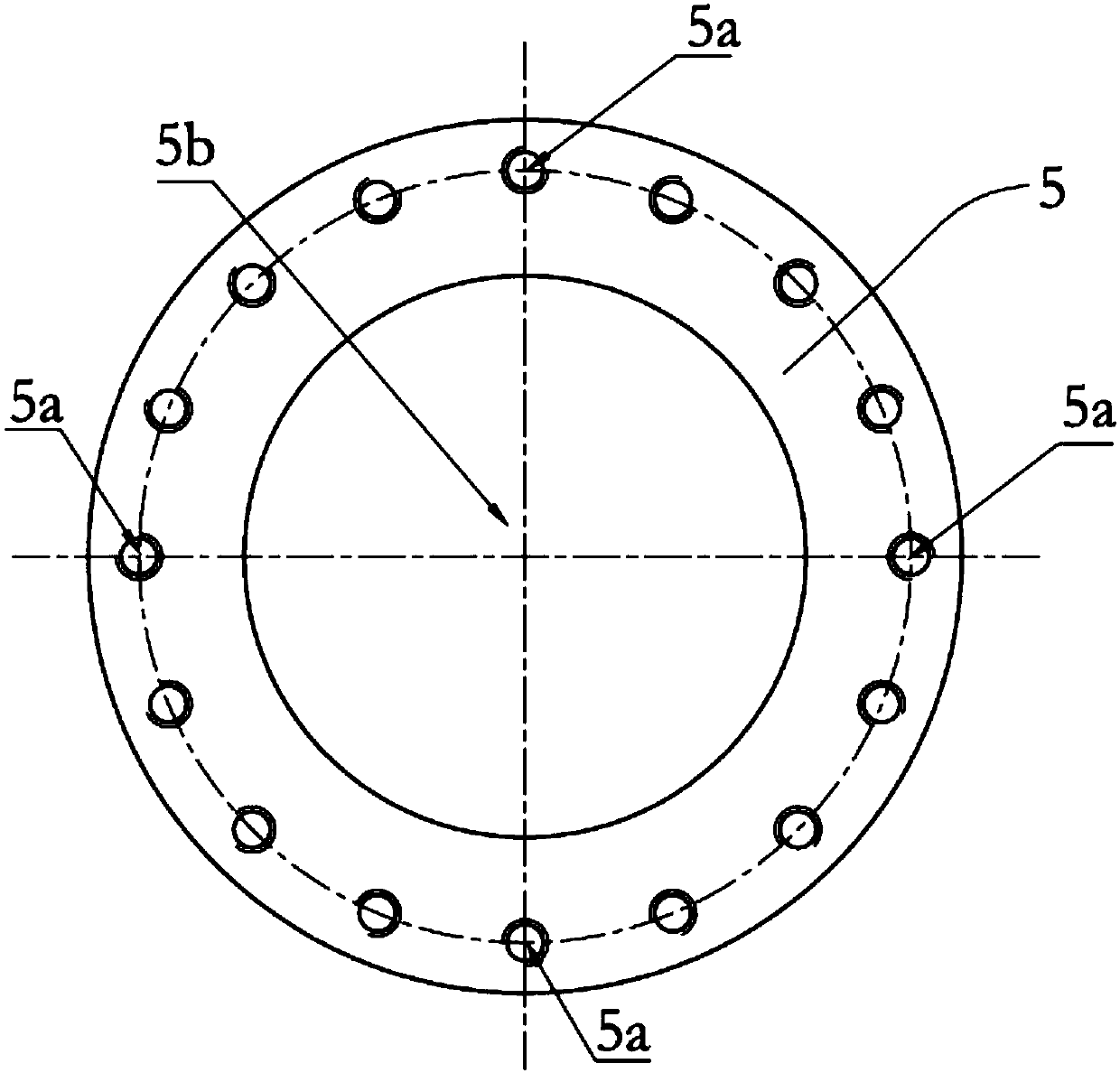

[0035] Such as Figure 1 to Figure 3 As shown, the double-sided flange 5 pipeline connection method in the present embodiment includes the following steps:

[0036] 1) Connect the equipment flange 3 to the equipment nozzle 1, connect the pipeline flange 4 to the pipeline nozzle 2, and perform preliminary alignment on the equipment and the pipeline, so that the center of the equipment flange 3 and the pipeline flange 4 are aligned, and make A gap is reserved between the two. It should be pointed out that after the initial alignment, the connecting end faces of the equipment flange 3 and the pipeline flange 4 are basically kept parallel, and the center of the equipment nozzle 1 is basically aligned with the center of the pipeline. It can simplify the subsequent construction work;

[0037] 2) Measure the distance between multiple quadrant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com