Backlight module and display device

A technology of backlight module and light source component, which is applied in the fields of reflection, display, diffraction, and backlight. It can solve problems such as poor display effect and uneven structural backlight, and achieve uniform light distribution, selectable, and uniform light output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

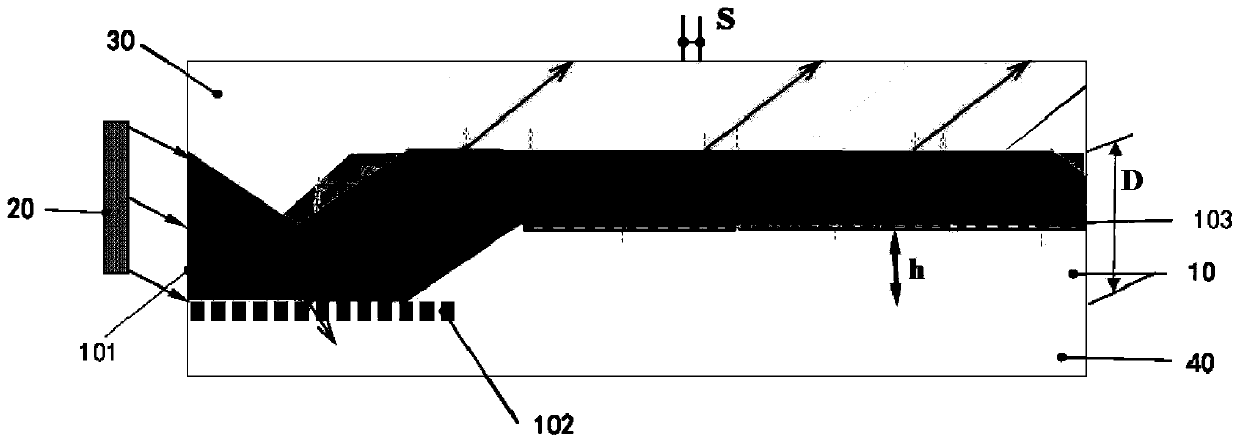

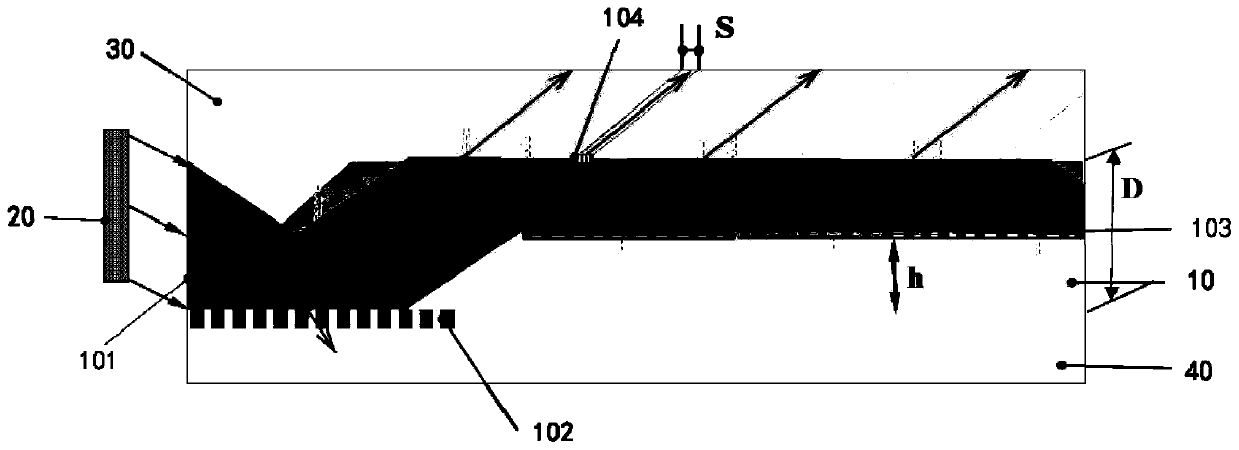

[0044] refer to figure 1 In one embodiment, the present invention provides that the light emitted by the light source assembly 20 enters the waveguide layer 10 through the light incident surface 101 at a preset angle, and then enters the waveguide layer 10 from the waveguide layer 10 The angle of the first grating layer 102 is the incident angle, the length of the first grating layer 102 is the product of the thickness of the waveguide layer 10 and the tangent of the incident angle, and the first grating layer 102 is close to the incident angle One end of the light surface 101 is flush with the light incident surface 101 . The length of the first grating layer 102 is the thickness of the waveguide layer 10 and the incident angle θ i The product of tangent values.

[0045] Specifically:

[0046] c=D×tanθ i

[0047] c is the length of the first grating layer 102, D is the thickness of the waveguide layer, θ i is the incident angle, the incident light can all be incident on...

Embodiment 2

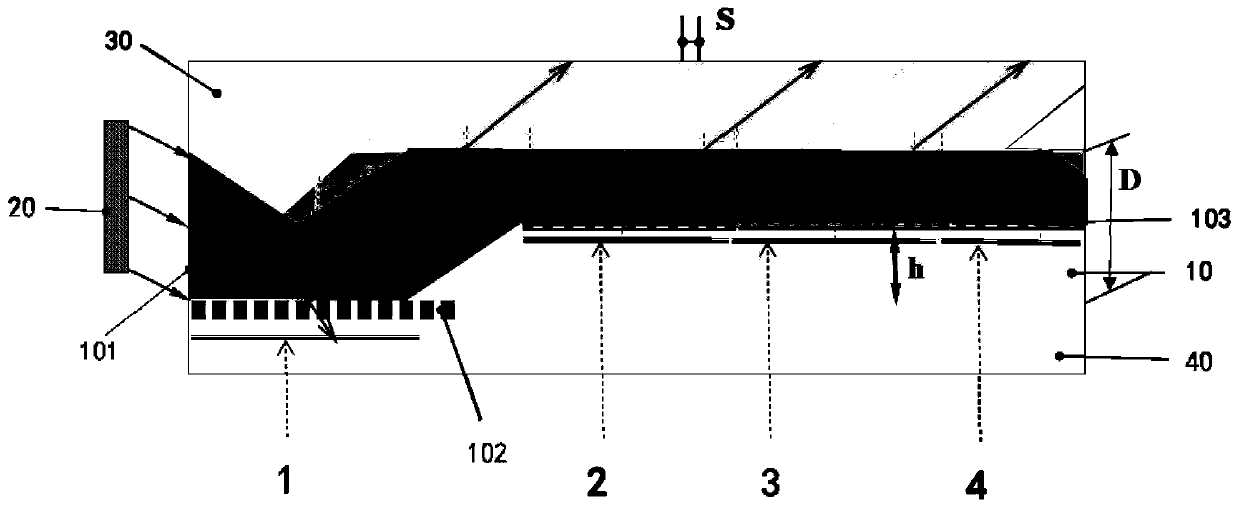

[0060] Such as Figure 4 As shown, in one embodiment, the present invention provides that the length of the first grating layer 102 is equal to the length of the waveguide layer 10, and the second grating layer 103 includes a plurality of grating groups 1031 arranged at intervals, The radiation area of each reflection of light at the light exit surface corresponds to one of the grating groups 1031, and one end of each grating group 1031 close to the light incident surface 101 is located at the corresponding periodic reflected light area close to the light incident surface 101 the edge of.

[0061] The first grating layer 102 is composed of a plurality of reflective grating components, and the second grating layer 103 is composed of a plurality of transmissive grating components. The first grating layer 102 and the second grating layer 103 can diffract light out of the light exit surface of the waveguide layer 10, and can enter the upper substrate 30 from the light exit surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com