Water seepage preventing performance testing method for floor

A testing method and flooring technology, which is applied in liquid-tightness measurement using liquid/vacuum degree, and detects the appearance of fluid at the leakage point, etc., can solve the problems of detecting the floor’s waterproof performance, moisture-induced arching deformation, etc., and is easy to obtain , cheap acquisition, and the effect of increasing the rate of high-quality products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A method for testing the water seepage resistance of a floor, comprising:

[0027] The first step, product sampling, specifically includes:

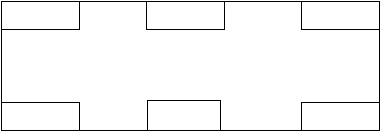

[0028] Step 1. Randomly select several floors in the same batch (such as figure 1 shown);

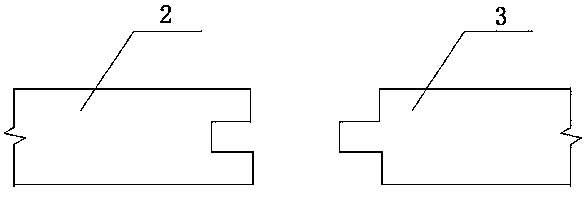

[0029] Step 2. Saw each floor into several sample floors with a length of 245 mm to 255 mm and a width equal to the width of the finished floor (such as figure 2 shown);

[0030] Step 3. Divide the sample floor into a pair, and make a floor groove test piece 2 on one grooved edge of each pair of the sample floor, and make a tenon matching the groove edge on the other sample floor. The edge is made into floor tenon specimen 3;

[0031] Step 4: splicing the floor groove test piece 2 and the floor tenon test piece 3 and storing them for 24 hours in an environment with an ambient temperature of 21° C. to 25° C. and a relative humidity of 45% to 55%.

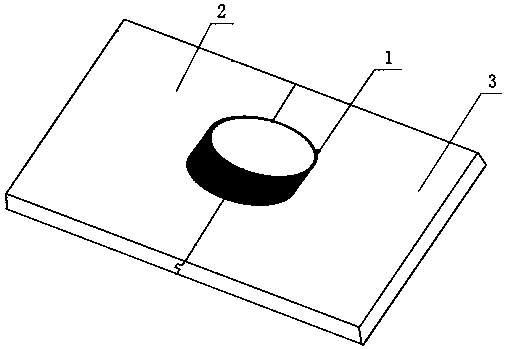

[0032] The second step is to paste the water-holding pipe 1 on the joint of the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com