Anti-radiation block for neutron science research and preparation method thereof

A technology for scientific research and radiation protection, applied in the field of radiation protection materials, can solve the problems of increasing the cost of concrete blocks, and achieve the effects of saving concrete costs, increasing radiation protection effects, and ingenious time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

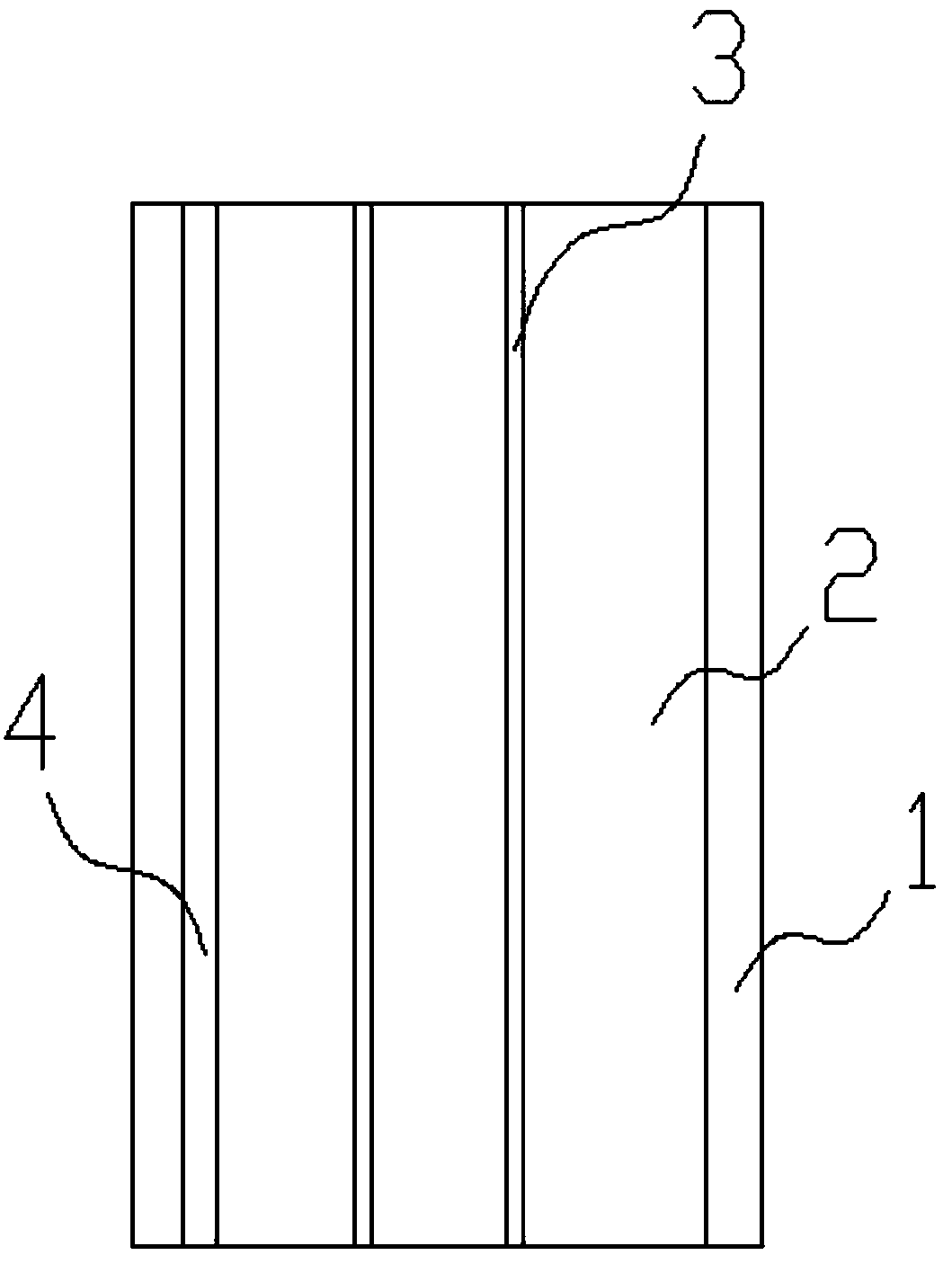

Image

Examples

Embodiment 1

[0026] A method for preparing a radiation-proof block for neutron scientific research, which comprises the following steps:

[0027] ①, Concrete slurry configuration, first prepare concrete slurry of different specifications through sand, copper particles, and cement of different specifications;

[0028] ②, the preparation of the combined block, pour the concrete slurry with the smallest sand size into the mold that can be heated outside, then smooth the upper part, then put a layer of plastic layer, and then pour the next sand size concrete slurry Inject on the plastic layer, smooth the upper part, and then put a layer of plastic layer on it, inject the subsequent concrete slurry and plastic layer according to the above method, no plastic layer needs to be placed on the upper part of the top concrete slurry, and then heat it through the outside of the mold The device heats the mold so that the temperature inside the mold reaches 80°C, and after heating for 15 minutes, it is a...

Embodiment 2

[0033] A method for preparing a radiation-proof block for neutron scientific research, which comprises the following steps:

[0034] ①, Concrete slurry configuration, first prepare concrete slurry of different specifications through sand, copper particles, and cement of different specifications;

[0035] ②, the preparation of the combined block, pour the concrete slurry with the smallest sand size into the mold that can be heated outside, then smooth the upper part, then put a layer of plastic layer, and then pour the next sand size concrete slurry Inject on the plastic layer, smooth the upper part, and then put a layer of plastic layer on it, inject the subsequent concrete slurry and plastic layer according to the above method, no plastic layer needs to be placed on the upper part of the top concrete slurry, and then heat it through the outside of the mold The device heats the mold so that the temperature inside the mold reaches 120°C, and after heating for 8 minutes, it is a...

Embodiment 3

[0040] A method for preparing a radiation-proof block for neutron scientific research, which comprises the following steps:

[0041] ①, Concrete slurry configuration, first prepare concrete slurry of different specifications through sand, copper particles, and cement of different specifications;

[0042] ②, the preparation of the combined block, pour the concrete slurry with the smallest sand size into the mold that can be heated outside, then smooth the upper part, then put a layer of plastic layer, and then pour the next sand size concrete slurry Inject on the plastic layer, smooth the upper part, and then put a layer of plastic layer on it, inject the subsequent concrete slurry and plastic layer according to the above method, no plastic layer needs to be placed on the upper part of the top concrete slurry, and then heat it through the outside of the mold The device heats the mold so that the temperature inside the mold reaches 100°C, and after heating for 11 minutes, it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com