Movable control mounting plate structure of AGV

A mounting plate and movable technology, which is applied in the field of AGV movable control mounting plate structure, can solve the problems of increasing the work intensity of maintenance personnel, affecting the progress of AGV maintenance, and labor-intensive screws, etc., and achieves difficult installation and disassembly, simple structure, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

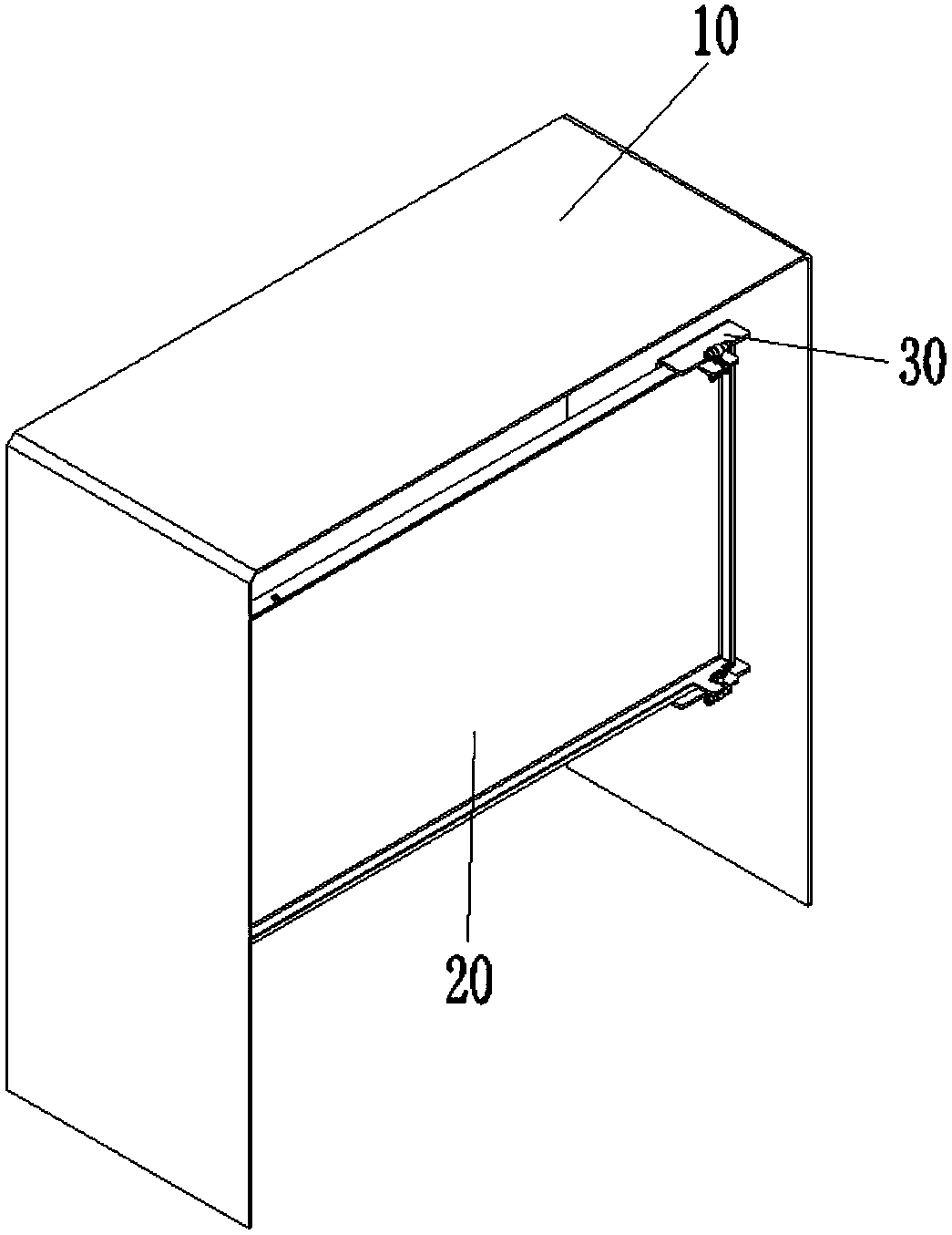

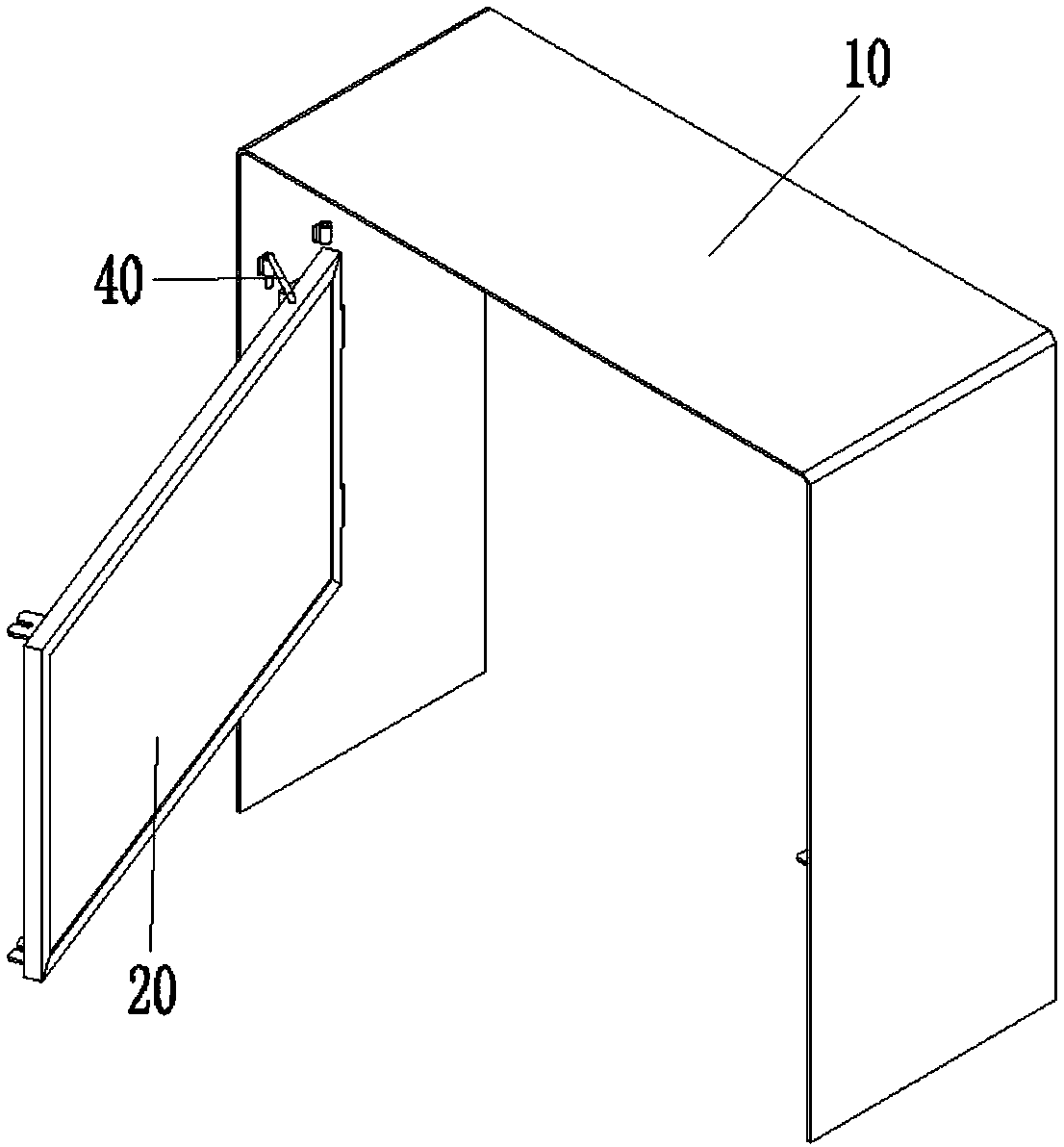

[0027] see figure 1 and figure 2 , the AGV movable control installation plate structure of the present invention includes an installation frame 10, a movable part 20, a fixed part 30 and a clamping part 40, and one end of the movable part 20 is pivotally connected to one side of the installation frame 10, so The fixing part 30 is fixed on the other side of the installation frame 10, the fixing part 30 is used to fix the free end of the movable part 20, and the locking part 40 is movably connected to the locking position of the installation frame 10. part and the clamping part of the movable part 20 to keep the movable part 20 at an opening angle.

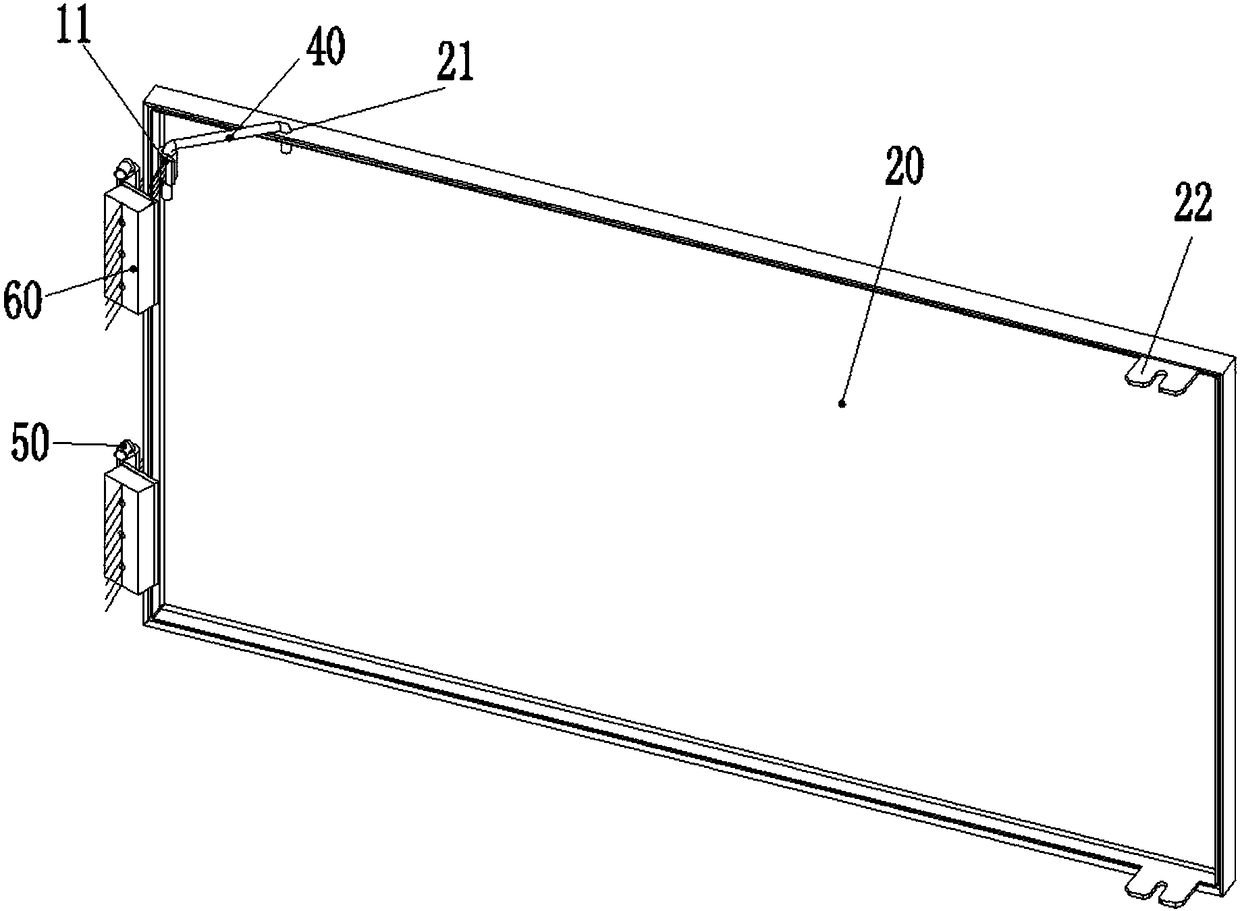

[0028] Specifically, see image 3 , Both the installation frame 10 and the movable part 20 are provided with locking parts. In this embodiment, the mounting frame 10 '' has a hook seat 11 , and the movable part 20 has a hook fixing hole 21 . The clamping parts 40 are respectively clamped on the support hook seat 11 and the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com