Arc workpiece size detection tool

A dimensional detection and arc-shaped technology, which is used in measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of time-consuming and laborious measurement, difficulty in measuring the size of arc-shaped workpieces, and outflow of defective products, so as to reduce the outflow of defective products. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

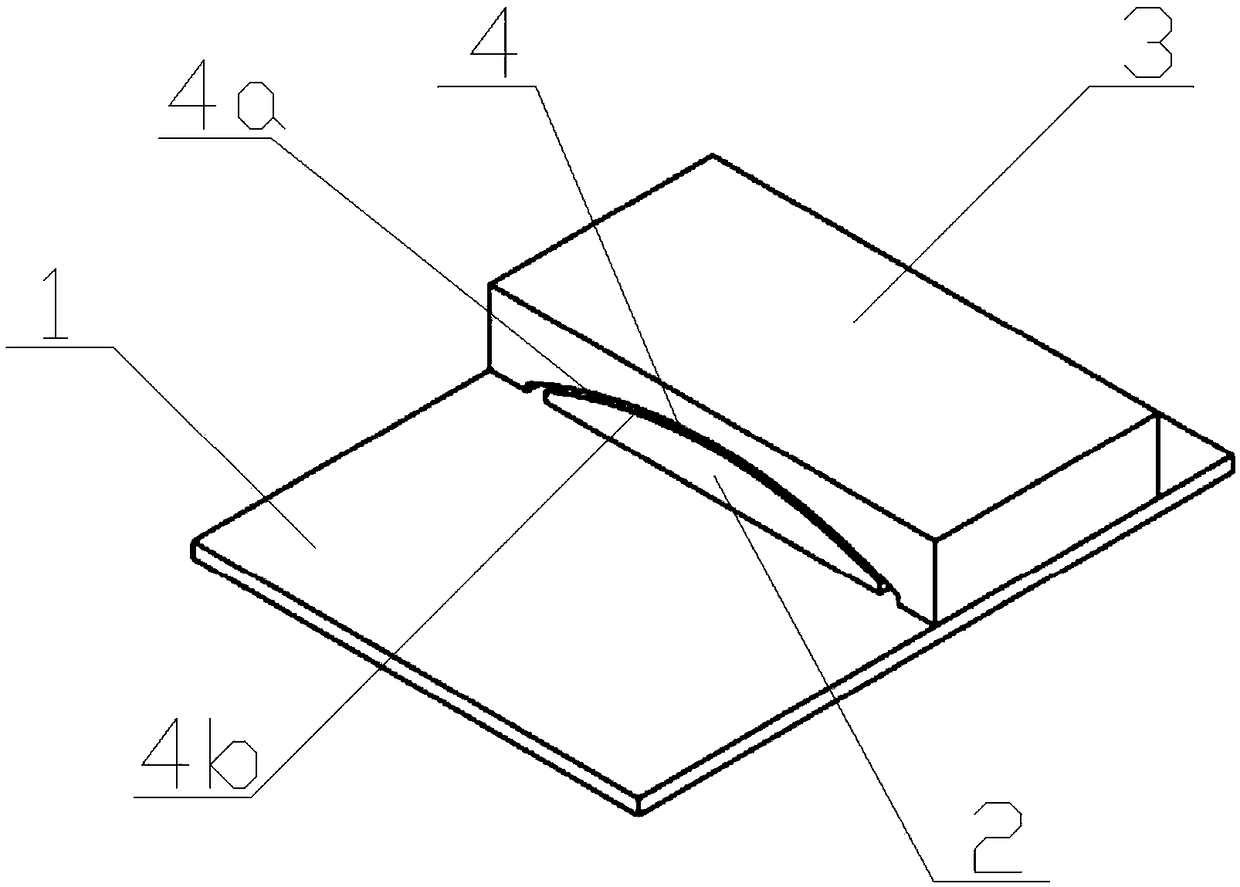

[0011] like figure 1 As shown, the arc size detection tool corresponding to a preferred embodiment of the present invention includes a bottom plate 1, an inner detection block 2 connected to the bottom plate 1 and an outer detection block 3, and the outer detection block 3 covers the inner detection block 2 On the surface, an arc-shaped gap 4 is formed between the outer detection block 3 and the inner detection block 2 . The dimensional accuracy and geometric tolerance of the arc gap 4 are very high. The size of the upper surface 4a of the arc gap 4 is the same as the maximum limit size of the upper surface of the arc workpiece. The lower surface of the arc gap 4 The dimension 4b is the same as the minimum limit dimension of the lower surface of the arc-shaped workpiece. That is, the arc-shaped ga...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap