Step type soilless culture device and culture method

A soilless cultivation, stepped technology, applied in the cultivation field of stepped soilless cultivation devices, can solve the problems of competition for nutrition, deformed shape, branches and leaves that cannot be formed into an expanded shape, etc., and achieves the effect of increasing the number of cultivation and ensuring perfection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

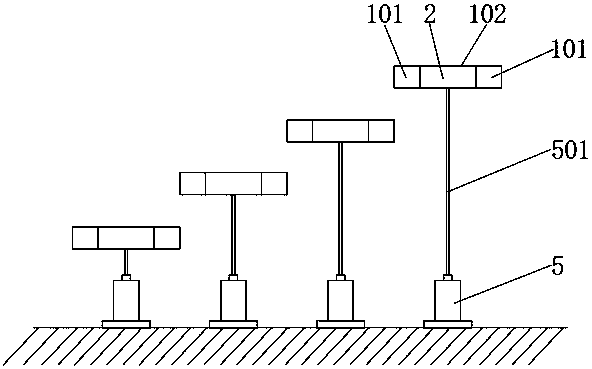

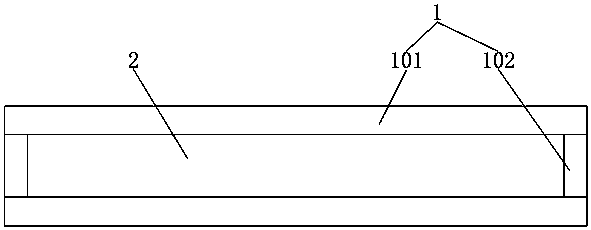

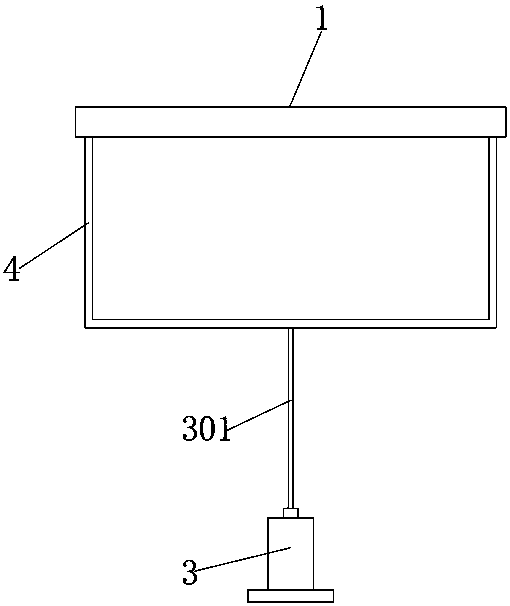

[0019] Example 1, please refer to Figure 1 to Figure 3 , the present invention provides a stepped soilless cultivation device, comprising a cultivation frame, the cultivation frame is composed of several potting frames 1 distributed in a plane; the potting frame 1 is composed of two transverse support bars 101 and respectively arranged The longitudinal connecting strips 102 on both sides of the bar 101 are formed, and the transverse supporting strips 101 are connected by the longitudinal connecting strips 102; a placement hole 2 is formed between the transverse supporting strips 101 and the longitudinal connecting strips 102; 1 is connected with a lifting mechanism that can make it move along the vertical direction.

[0020] Described elevating mechanism comprises the first air cylinder 3 that is located at potted plant frame 1 below; The piston rod 301 of described first air cylinder 3 is connected with a U-shaped support frame 4; The center position below the bar 102.

[...

Embodiment 2

[0022] Embodiment two, refer to figure 1 , figure 2 and Figure 4 , a step-type soilless cultivation device, comprising a cultivation frame, the cultivation frame is composed of several potting frames 1 distributed in a plane; Side vertical connecting strips 102 are formed, and the horizontal supporting strips 101 are connected by the vertical connecting strips 102; the horizontal supporting strips 101 and the longitudinal connecting strips 102 are surrounded to form a placement hole 2; the potted frame 1 is connected with A lifting mechanism that moves it vertically.

[0023] The lifting mechanism includes second air cylinders 5 respectively arranged below the longitudinal connecting bars 102 ; the piston rod 501 of the second air cylinders 5 is connected to the central position below the longitudinal connecting bars 102 .

[0024] In this embodiment, when the height of the potting frame is adjusted, the second cylinder 5 positioned at both sides of the potting frame 1 ca...

Embodiment 3

[0025] Embodiment three, refer to figure 1 , figure 2 and Figure 5 , a step-type soilless cultivation device, comprising a cultivation frame, the cultivation frame is composed of several potting frames 1 distributed in a plane; Side vertical connecting strips 102 are formed, and the horizontal supporting strips 101 are connected by the vertical connecting strips 102; the horizontal supporting strips 101 and the longitudinal connecting strips 102 are surrounded to form a placement hole 2; the potted frame 1 is connected with A lifting mechanism that moves it vertically.

[0026] A suspension rod 6 is arranged directly above the potting frame 1; both ends of the suspension rod 6 are connected to the longitudinal connecting strips 102 on both sides of the transverse support bar 101 through a wire rope 7; the middle part of the suspension rod 6 is connected to a guide Rope 8; the top of the suspension rod 6 is provided with a first guide wheel 9 matched with the guide rope 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com