Shock absorbing helmet manufacturing and mounting technology

An installation process and safety helmet technology, which is applied in the field of shock-absorbing safety helmet manufacturing and installation process, and can solve problems such as the inability to guarantee product quality requirements and product functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

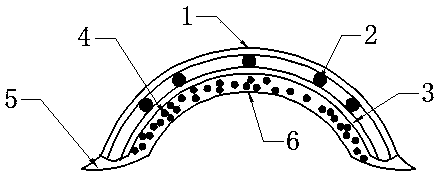

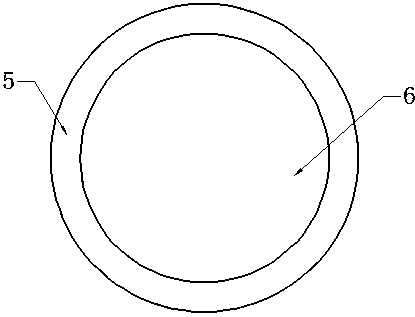

[0010] Taking the shock-absorbing helmet as an example, plastic steel is pressed to form a crown helmet with a brim 5. Hard plastic is injected into a liner helmet. Made of cloth with a cap lining 6 with a shockproof layer 4—the concave surface of the top helmet 1 is connected to the top surface of the lining helmet 3 with a shock absorbing spring 2—a cap lining 6 with a shockproof layer 4 is installed in the concave surface of the lining helmet 3—the whole Inspection—function test: the external force hits the top helmet 1, the shock absorbing spring 2, and the shockproof layer 4 slow down the shock force and impacts the inside of the cap 6, and it is qualified to realize the above functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com