Patents

Literature

101results about How to "The processing, installation and production process follows the rules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

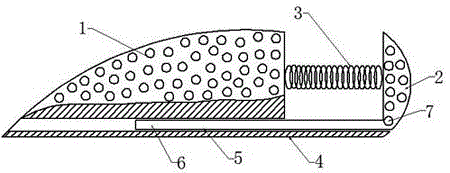

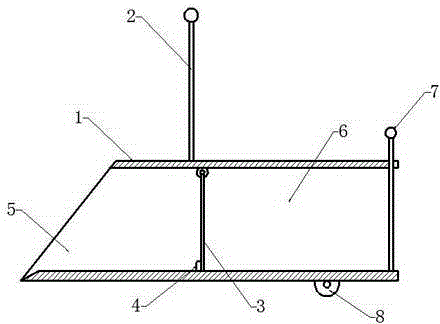

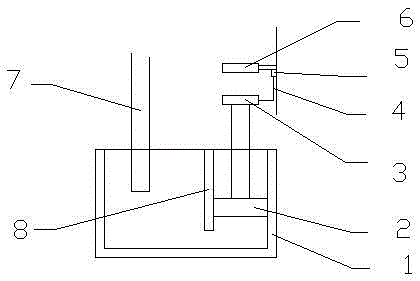

Manufacturing and installing technology for elastic foot mold shoe stretcher

InactiveCN106827369AGuarantee product qualitySave raw materialsCoatingsEngineeringInjection molding machine

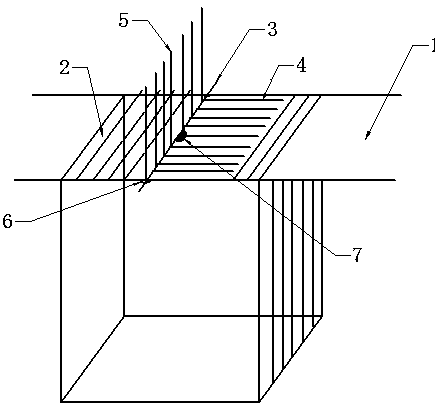

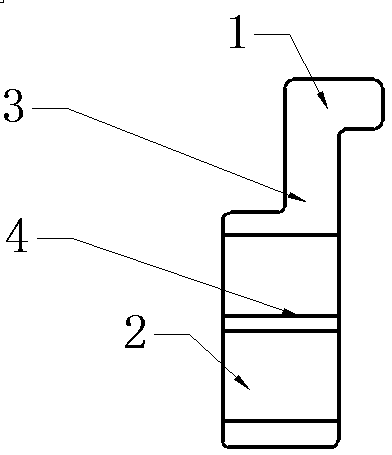

The production and installation process of the elastic foot mold shoe support is to use ABS raw materials on the injection molding machine to injection mold the upper support 1 with the slideway 5 and the air hole 7 and the bottom plate 4, and the telescopic back support 2 blank with the sliding guide rod 6 ——Removing burrs, polishing, and dredging the air holes 7 and dredging the slideway 5 for each blank——Inserting the sliding guide rod 6 of the telescopic rear support 2 into the slideway 5 of the shoe upper support 1——Using the support spring 3 to hold the shoe support surface 1. The rear end and the front end of the shoe back support 2 are fixed and cannot be disengaged. The manufacturing and installation process of the elastic foot mold shoe support can be produced and installed in an orderly manner in accordance with the specifications, so as to ensure the manufacturing quality and requirements of the product and reduce irrelevant and unnecessary links, and can save raw materials, reduce costs, and the processing, installation and production process is compliant, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

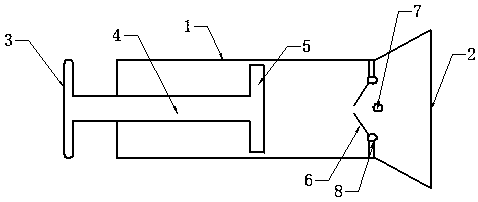

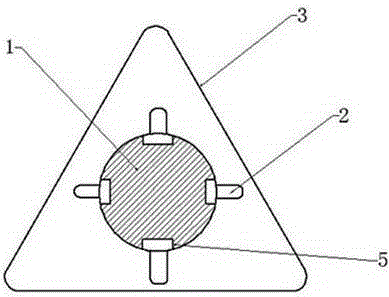

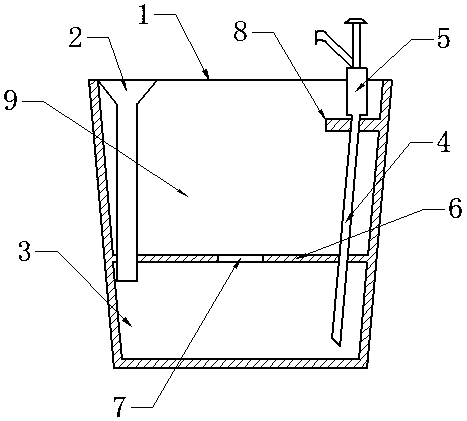

Manufacturing and installing process for cylindrical air-exhaust type mosquito killing device

InactiveCN108056080AGuarantee product qualitySave raw materialsInsect catchers and killersEngineeringScrew thread

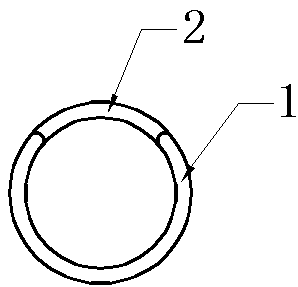

Provided is a manufacturing and installing process for a cylindrical air-exhaust type mosquito killing device. The process comprises: performing injection molding using plastics in a special die, to form a draw tube with a suction port, a pumping rod, a pumping handle, and a one-way door; removing burrs on inner and outer surfaces of the draw tube, the pumping rod, the pumping handle, and the one-way door, polishing, making threads for the pumping rod; pressing rubber into a piston, drilling a screw hole, removing burrs, and finishing; performing turning on a door shield and a door spindle, and polishing, cleaning, and galvanizing; putting the piston into the draw tube from the suction port, holding the pumping handle to insert the pumping rod from the upper end of the draw tube, abuttingand tightly screwing the pumping rod with the piston screw hole in the draw tube; using the door spindle to install the one-way door and the door shield on the suction port; performing integrated checking; and performing function tests. The manufacturing and installing process for a cylindrical air-exhaust type mosquito killing device performs production and installation in order according to specifications, to ensure manufacturing quality and requirements of products. Unrelated and unnecessary steps are reduced, raw materials are saved, and cost is reduced. Processing and installation production processes keep on the rails and are safe and in order.

Owner:QINGDAO CENTURY YUNFAN IND

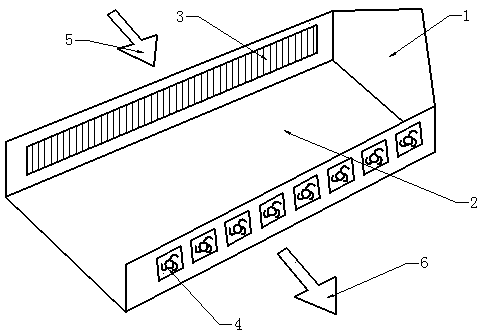

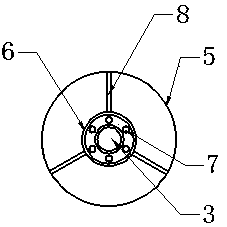

Draught fan water curtain combination ventilation and cooling system assembling and debugging technology

InactiveCN108064700AGuarantee product qualitySave raw materialsAnimal housingBird housingsWater filterAgricultural engineering

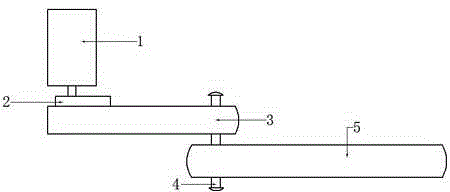

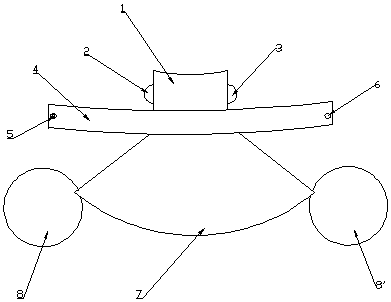

The invention relates to a draught fan water curtain combination ventilation and cooling system assembling and debugging technology. The technology comprises the steps that a water filter curtain is installed on the front wall of a ventilation space of a livestock house, circulating water is received, N single-way draught fans corresponding to the water filter curtain are installed on the wall opposite to the front wall of the ventilation space of the livestock house, the water filter curtain and the draught fan are correspondingly debugged, and air inlet direction and the air outlet directionare determined. According to the draught fan water curtain combination ventilation and cooling system assembling and debugging technology, orderly production and installation can be conducted according to specifications, so that the product manufacturing quality and requirements are guaranteed, irrelevant and unnecessary links are reduced, raw materials can be saved, the cost can be lowered, andthe processing and installing production process follows the rules and is safe and orderly.

Owner:QINGDAO MUGANG LIVESTOCK MACHINERY CO LTD

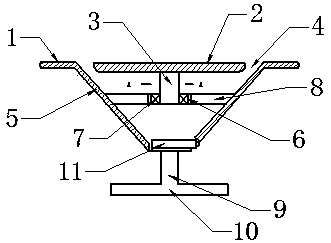

Manufacture and installation process of dining table with garbage box

InactiveCN108065596AGuarantee product qualitySave raw materialsRevolvable tablesFeetSoftware engineeringManufacturing quality

The invention provides a manufacture and installation process of a dining table with a garbage box. A base support shaft is installed at the center of a base for fixing a table body of a with-edge table; the lower side of the center of the table body is provided with a fixing support beam, a supporting bearing base, an installation bearing and a rotating support shaft; the center of the lower surface of an inner table is fixedly installed at the upper end of the rotating support shaft, and an uniform isolation space is kept between the inner table and the with-edge table; the lowermost end inthe table body is provided with a garbage drawer; the inspection of the overall surface and the installation firmness is conducted; the function inspection is conducted. According to the manufacture and installation process of the dining table with the garbage box, orderly production and installation can be conducted according to the specification, the manufacture quality and requirement of products are ensured, unrelated and unnecessary links are reduced, raw materials can be saved, the cost is reduced, and the processing, manufacture and installation processes observe all rules and regulations, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

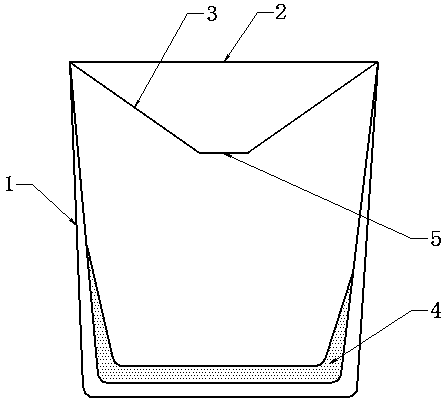

Manufacturing and installation process for buffered fruit-receiving basket

InactiveCN108012667AEasy to makeSimplify the installation processPicking devicesManufacturing qualityPlastic foam

The invention provides a manufacturing and installation process for a buffered fruit-receiving basket. According to the invention, wickers are woven into a fruit basket with a large basket opening; cotton threads are knitted into a buffer net with a fruit-dropping opening in a central position; plastic foam is made into a lining which is laid on the bottom part of the fruit basket; the buffer netwith the fruit-dropping opening in the central position is arranged on the basket opening; and overall inspection and function test are performed. The manufacturing and installation process for the buffered fruit-receiving basket provided by the invention can realize ordered production and installation according to specification, guarantees the manufacturing quality and requirements of a product,reduces unrelated and unnecessary links, can save raw materials, reduces the cost, and follows rules and regulations and is safe and ordered in the processes of processing, installation and production.

Owner:QINGDAO CENTURY YUNFAN IND

Manufacturing and mounting technology of sliding dustpan with backflow blocking plate

InactiveCN106812106AGuarantee product qualitySave raw materialsRoad cleaningEngineeringInjection moulding

The production and installation process of the sliding rubbish with a backflow baffle, the rubbing body with the shaft seat and the stopper, the anti-reflux plate with the shaft seat and the blank of the plug-in plate-with the shaft seat and the stopper are injection-molded on the injection molding machine with ABS raw materials The rubbing body, anti-backflow plate with shaft seat, deburring, grinding, and cleaning of the inner and outer surfaces of the inserting plate - install handles on both sides of the upper part of the rubbing body - use pin shafts at the entrance to insert the anti-backflow plate into the rubbing body The shaft seat is connected with the shaft seat of the rubbing body - the inserting plate is installed behind the rubbing body, and the garbage bin is formed between the inserting plate and the anti-backflow baffle - two runners are installed at the rear end of the bottom surface of the rubbing body, and the slide of the belt backflow baffle The production and installation process of the rubbing can be produced and installed in an orderly manner in accordance with the specifications to ensure the manufacturing quality and requirements of the product, reduce irrelevant and unnecessary links, and can save raw materials and reduce costs. The processing, installation and production process is compliant, safe and effective sequence.

Owner:QINGDAO CENTURY YUNFAN IND

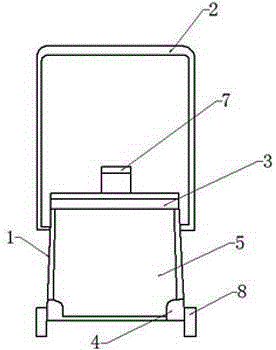

Elastic safety protective guard manufacturing and installing technology

InactiveCN106809155AGuarantee product qualitySave raw materialsVehicular safety arrangmentsFixed frameManufacturing quality

The production and installation process of the elastic safety fence is to weld the turned spring seat on the fixed frame made of angle steel—weld the spring seat matching telescopic shaft on the movable frame made of angle steel—put the spring seat of the fixed frame into the telescopic spring, and use the movable The telescopic shaft of the beam is inserted into the spring seat to withstand the telescopic spring—three support springs are installed between the fixed frame and the movable frame to connect, and the fixed frame and the movable frame are integrated—the surface is deburred, polished and painted, and the elastic safety fence The production and installation process can be produced and installed in an orderly manner in accordance with the specifications to ensure the manufacturing quality and requirements of the product, reduce irrelevant and unnecessary links, and save raw materials and reduce costs. The processing, installation and production process is regulated, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

Manufacturing and installing process of spiral lever type mechanical crowbar

Manufacturing and installation process of screw lever mechanical crowbar, parts processing: ball milled iron casting seat body, fixed screw seat integrated, drilling fixed screw seat thread, drilling lever shaft hole, overall surface grinding, rust removal, polishing, painting-turning processing screw and Welding handle - forging and processing adjustable pry bar and tilting head - turning and processing lever shaft - forging and processing lifting lever and drilling lever shaft hole and screw screw hole; assembly: connecting the lifting lever with the lever shaft on the top of the seat body - lifting lever The front end is fixed with a pry head and an adjustable pry bar—a screw with a rocker is installed in the screw hole at the rear end of the lifting lever, and the lower end of the screw is screwed into the fixed screw seat. The production and installation process of the screw lever mechanical crowbar can be produced in an orderly manner according to the specifications. Installation to ensure the manufacturing quality and requirements of the product, reduce irrelevant and unnecessary links, save raw materials and reduce costs, and the processing, installation and production process follows the rules, is safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

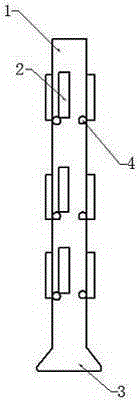

Assembly process of clothing rack with retractable hooks

InactiveCN106808553AGuarantee product qualitySave raw materialsWood working apparatusManufacturing qualityVarnish

Clothes hanger assembly process where the clothes hook can be put away. Wooden materials are used on woodworking machinery to process the middle column of the hanger—N slots for clothes hooks are processed from top to bottom in the four directions of the middle column of the hanger—turning with an instrument lathe N pieces of wooden clothes hooks—the center pillar of the clothes hanger, the surface of the clothes hanger is polished to remove processing burrs, polished with 300 mesh emery cloth, and the surface is coated with varnish—casting base, surface derusted and deburred, polished, sprayed—install the middle pillar of the clothes hanger Base—Use metal bolts as the rotating shaft to install the clothes hook at the lower end of the clothes hanger groove in the middle column of the clothes hanger. The clothes hanger assembly process that can be put away by the clothes hanger can be produced and installed in an orderly manner in accordance with the specifications to ensure the manufacture of the product Quality and requirements, reduce irrelevant and unnecessary links, save raw materials, reduce costs, and make the processing, installation and production process follow the rules, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

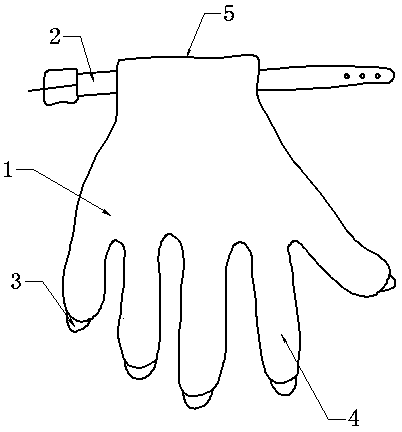

Manufacturing process of profiling excavation glove

InactiveCN108056516ASave materialGuarantee product qualityGlovesProtective garmentPunch pressSheet steel

Provided is a manufacturing process of profiling excavation gloves. The process comprises: selecting wear resistant steel plates, stamping by a special mold on a punching machine, to form steel fingernails, polishing, blueing; using the steel fingernails as inserts to put in a glove injection molding special mold; using rubber which is wear resistant and good in air permeability to make a left profiling glove and a right profiling glove with the steel fingernails in the glove injection molding special molds which hold the steel fingernail inserts; using leather to make a lacing, and sewing thelacing on a glove mouth; performing integrated checking; and performing function tests. The manufacturing process of profiling excavation gloves performs production and installation in order according to specifications, to ensure manufacturing quality and requirements of products. Unrelated and unnecessary steps are reduced, raw materials are saved, and cost is reduced. Processing and installation production processes keep on the rails and are safe and in order.

Owner:QINGDAO CENTURY YUNFAN IND

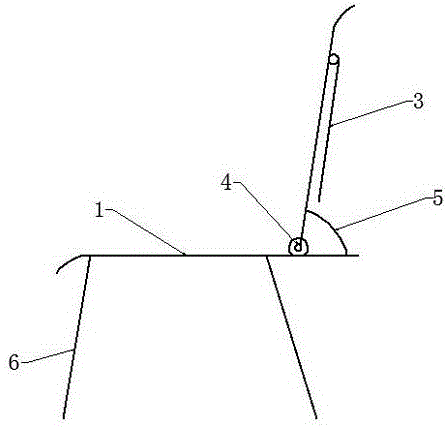

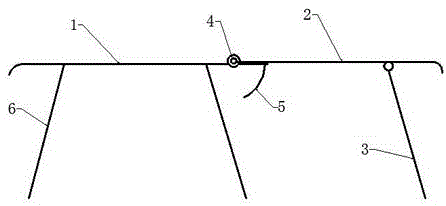

Production assembling process for chair-to-bed transforming equipment

InactiveCN106820736AGuarantee product qualitySave raw materialsSofasWood working apparatusBiochemical engineeringMaterials processing

The production and assembly process of the chair and bed transformation tool is to use wooden materials to process the seat board and the back board to deburr the surface - install the fixed legs on the bottom of the seat board - install the movable legs on the back of the back board - connect the back board to the back of the seat board with a rotating shaft End—A semicircular support is installed at the junction of the seat board and the back board. The manufacturing and assembly process of the chair and the bed transformation tool can be produced and installed in an orderly manner in accordance with the specifications, so as to ensure the manufacturing quality and requirements of the product and reduce irrelevant and unnecessary links. , and can save raw materials, reduce costs, and the processing, installation and production process is compliant, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

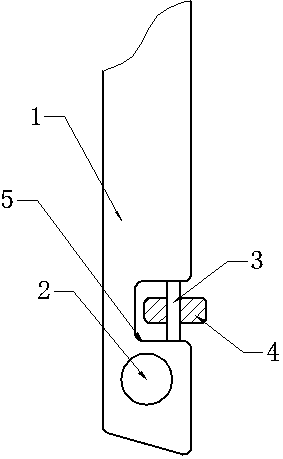

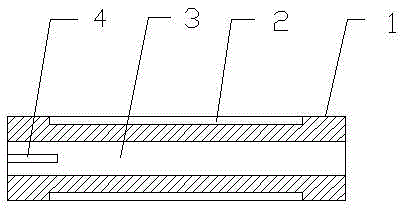

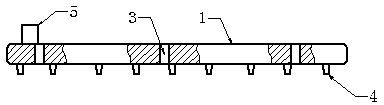

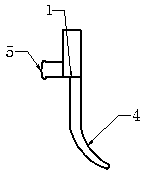

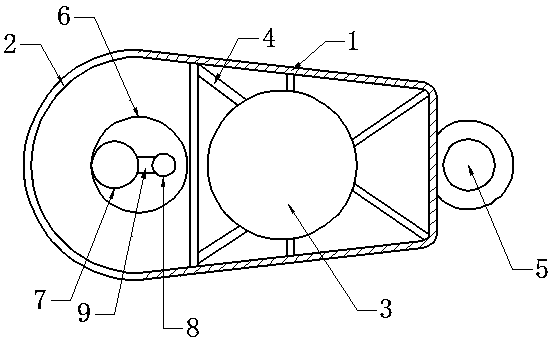

Improved band pulley feeding frame manufacturing and installing process

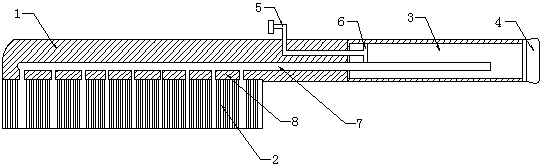

The invention relates to an improved band pulley feeding frame manufacturing and installing process, which comprises the steps of die-casting a zinc alloy to mold a feeding frame workblank piece witha screw rod bolt hole and a groove; deburring an outer surface of the feeding frame, drilling and tapping the screw rod bolt hole, finishing the groove, and drilling a vertical shaft hole; derusting,polishing, cleaning, phosphating and electrostatically spraying the surface of the feeding frame; installing a vertical shaft assembled with a rotating wheel in the groove; assembling the screw rod bolt hole of the feeding frame onto a screw rod; wholly inspecting; and testing functions. According to the improved band pulley feeding frame manufacturing and installing process, orderly production and installation can be carried out according to specifications, so that the manufacturing quality and the requirements of products are ensured, unrelated and unnecessary links are reduced, raw materials can be saved, the cost is reduced, and a processing and installation production process observes all rules and regulations, and is safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

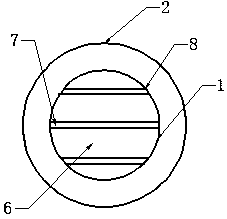

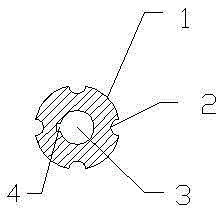

Manufacturing process for rotary automatic workpiece conveying grooved roller

The manufacturing process of the grooved roller that automatically transports the workpiece by rotation, takes the round steel of the corresponding length and turns the outer circular grooved roller blank on the lathe—drills the shaft hole on the drilling machine—mills the keyway on the milling machine—mills the outer circular groove of the grooved roller on the whirlwind milling machine, the rotation The grooved roller manufacturing process that automatically transports the workpiece can be produced and installed in an orderly manner in accordance with the specifications to ensure the manufacturing quality and requirements of the product, reduce irrelevant and unnecessary links, and save raw materials and reduce costs. The processing, installation and production process follows rules and regulations. Safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

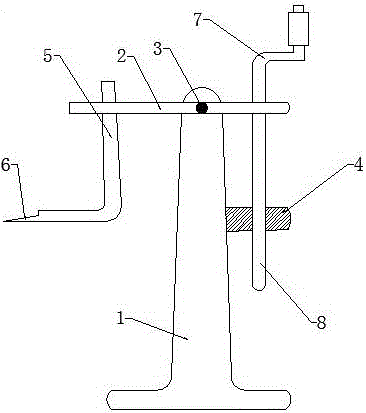

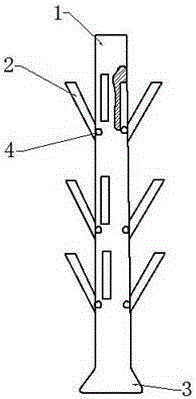

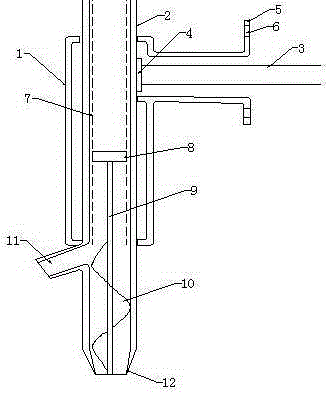

Manufacturing and mounting process of power transmission tree well digging machine

InactiveCN106804159AGuarantee product qualitySave raw materialsPlantingFurrow making/coveringGear wheelScrew thread

Power transmission tree digging machine manufacturing and installation process, all components are professionally manufactured and inspected for assembly: install the power shaft with power turbine in the upper horizontal body of the outer body - install the power connection plate with connecting shaft holes on the outer side of the outer body - outer body A hollow worm with an internal transmission thread is installed in the vertical body, and a soil discharge port is installed outside the vertical body—the transmission gear is installed on the upper end of the transmission rod with a spiral plate and fastened into one body, and the overall installation is connected to the internal transmission thread in the hollow worm, The bottom end of the spiral piece is flush with the digging opening. The manufacturing and installation process of the power transmission tree digging machine can be produced and installed in an orderly manner in accordance with the specifications, so as to ensure the manufacturing quality and requirements of the product, reduce irrelevant and unnecessary links, and save cost. Materials and materials are reduced, costs are reduced, and the processing, installation and production process is regulated, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

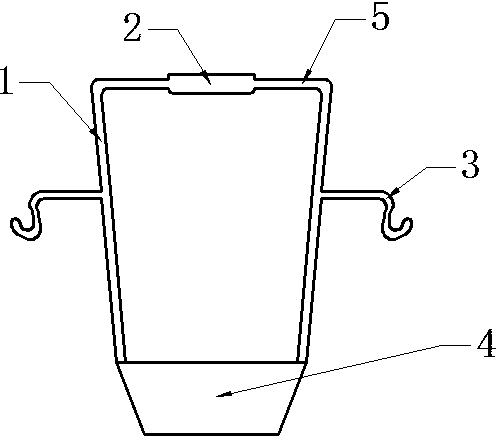

Manufacturing technology of feeding cup fixed through two hooks

InactiveCN108064715AGuarantee product qualitySave raw materialsAnimal feeding devicesAvicultureManufacturing technologyInjection moulding

The invention discloses a manufacturing technology of a feeding cup fixed through two hooks. The technology includes the steps that a non-toxic plastic raw material is used for manufacturing a foddercup, a vertical rod with the transverse hooks, and a transverse rod in an injection molding mode; the surface of the fodder cup, the surface of the vertical rod with the transverse hooks and the surface of the transverse rod are subjected to burring and polishing; a zinc-plated pipe is manufactured into a hanging pipe, and the hanging pipe is subjected to grinding, polishing and paint spraying; the hanging pipe penetrates through the transverse rod; the two ends of the transverse rod are connected to the upper end of the vertical rod in a plastic welding mode; the lower end of the vertical rodis connected with the upper edge of the fodder cup in a plastic welding mode; a plastic welding opening is cleaned, and overall polishing is conducted; inspection and function testing are conducted.The manufacturing technology of the feeding cup fixed through the two hooks can be used for orderly production and installation according to standards to guarantee the manufacturing quality and requirements of products and reduce irrelevant and unnecessary links; the raw material can be saved, the cost is reduced, and the processing, installation and production processes conform to the standards and are safe and orderly.

Owner:QINGDAO MUGANG LIVESTOCK MACHINERY CO LTD

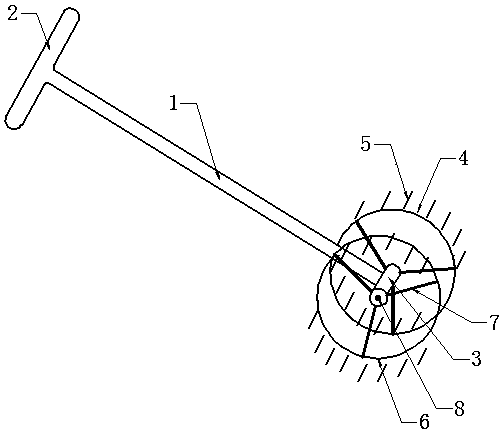

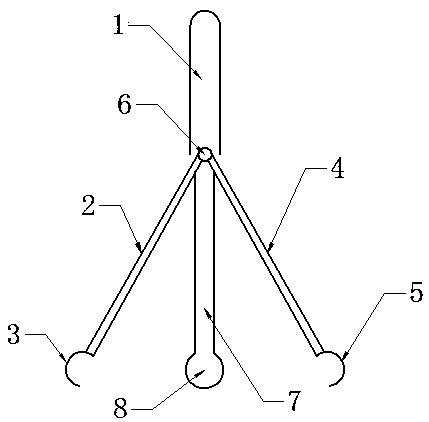

Manufacturing and installing technology for rotating wheel inter-row weeder

InactiveCN108064471AGuarantee product qualitySave raw materialsSpadesShovelsFunctional testingCarbonization

Provided is a manufacturing and installing technology for a rotating wheel inter-row weeder. The technology includes the steps that a common steel tube is made into a push rod with a handle, and polishing is carried out; steel bars are welded into left and right hubs with spokes and break shovels, and appearance polishing and carbonization are carried out; turning is carried out to form an axle and an axle sleeve, and quenching and blueing are carried out; the axle sleeve is installed at the lower end of the push rod through welding, and the axle is assembled in the axle sleeve; the left and right hubs are installed at the two ends of the axle and fixed, and the break shovels on left and right rotating wheels extend out; overall inspection is carried out; functional testing is carried out.By means of the manufacturing and installing technology for the rotating wheel inter-row weeder, orderly production and installation can be carried out according to standards to ensure the product manufacturing quality, meet the product manufacturing requirement and reduce irrelevant and unnecessary links; besides, raw materials can be saved, costs can be reduced, and the processing, installationand production process conforms to rules and regulations and is safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

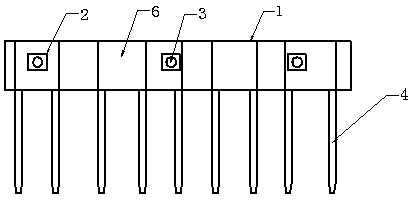

Manufacturing process of special long-tooth egg outlet raker matched to egg collection belt

InactiveCN108068373AGuarantee product qualitySave raw materialsDomestic articlesOrder processingInjection molding machine

The invention relates to a manufacturing process of a special long-tooth egg outlet raker matched to an egg collection belt. According to the manufacturing process, a fixation beam and raking-egg tooth integrated billet member with a nail stabilization column is prepared from a non-toxic plastic raw material through injection molding with an injection molding machine; after mold stripping, integrated billet member is rapidly placed into a fixation cooling mold, and internal shaping is performed (the straightness of the fixation beam, ie., the uniformity of the raking-egg teeth, is maintained);after the shaping, the mold is removed, burrs are removed, and burnishing is performed; a counter bore and a bolt hole are drilled; an egg sliding channel, the raking-egg teeth and the nail stabilization column are finished; integrated polishing is performed, and inspection is performed; and an installation experiment is performed. According to the present invention, with the manufacturing process, the ordered production and installation can be performed according to the specification so as to ensure the manufacturing quality and the requirements of the product, reduce the unnecessary links,save the raw material, reduce the cost, and achieve the regular, safe and ordered processing installation and production process.

Owner:QINGDAO MUGANG LIVESTOCK MACHINERY CO LTD

Trap type rat trapping cage manufacture and installation process

InactiveCN108064836ASave materialGuarantee product qualityAnimal trapsManufacturing qualityEngineering

Provided is a trap type rat trapping cage manufacture and installation process. A rat trapping cage woven by metal wires, a movable pedal with a rotating shaft, and a movable cover plate integrated part are arranged, bearings are installed on both sides of a plane of the rat trapping cage, rotating shafts of the movable pedal and the movable cover plate integrated part are installed on the bearings, springs are installed between the movable cover plate and edges of the rat trapping cage, baits are placed in midpoints of included angles between the movable pedal and the movable cover plate, integral inspection is conducted, and functional testing is conducted. The trap type rat trapping cage manufacture and installation process can perform orderly production and installation according to the norms, manufacture quality and requirements of products are ensured, irrelevant and unnecessary links are reduced, raw materials are saved, costs are reduced, and a processing installation and production process is in accordance with rules and regulations, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

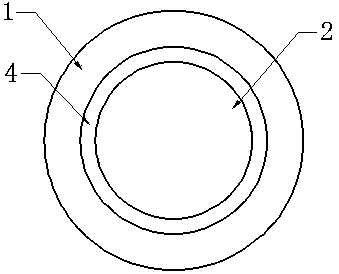

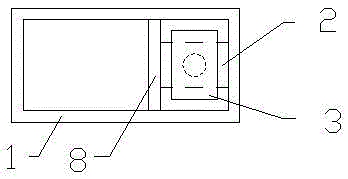

Manufacture and installation process of water-saving washing machine with storage tank

InactiveCN108070988AGuarantee product qualitySave raw materialsOther washing machinesTextiles and paperWater savingWater storage tank

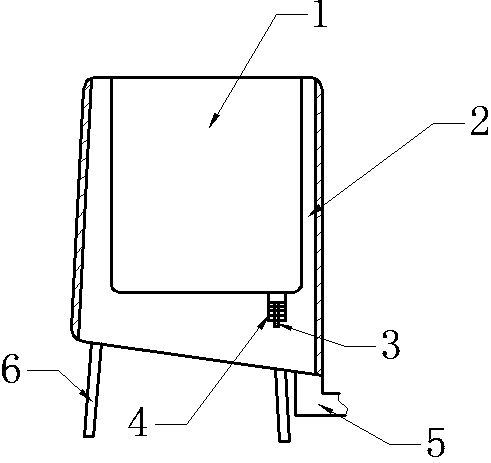

The invention provides a manufacture and installation process of a water-saving washing machine with a storage tank. A semifinished water-storage-tank product corresponding to the size and shape of the washing machine is formed from plastic through injection in a mold of a large injection molding machine; the semifinished water-storage-tank product is deburred, and the inner side and outer side ofthe semifinished water-storage-tank product is polished; a water storage tank is provided with a water-storage-tank valve and an adjustable support leg; a washing-machine water drain valve on the bottom of the washing machine is provided with a one-way valve; the washing machine is installed in the water storage tank, the contact edge is sealed, and fixation is conducted; overall quality inspection is conducted; function inspection is conducted. According to the manufacture and installation process of the water-saving washing machine with the storage tank, orderly production and installationcan be conducted according to the specification, the manufacture quality and requirement of products are ensured, unrelated and unnecessary links are reduced, raw materials can be saved, the cost is reduced, and the processing, manufacture and installation processes observe all rules and regulations, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

Manufacturing and installing technology for electric rotary beetling stick

InactiveCN106826101ASave materialGuarantee product qualityPortable percussive toolsElectric machineryEngineering

Production and installation process of electric rotating mallets, accessories processing: turning eccentric wheel with round steel, drilling - turning round steel, processing rotating stick, hammering stick, rotating shaft - rotating stick, hammering stick drilling - turning stick, hammering stick, rotating shaft surface removal Burr polishing; assembly: assemble the eccentric wheel on the motor shaft - install the rear end of the rotating stick on the eccentric wheel - link the hammering stick with the rotating shaft at the front end of the turning stick. The manufacturing and installation process of the electric rotating mallet stick can be produced and installed in an orderly manner , to ensure the manufacturing quality and requirements of the product, reduce irrelevant and unnecessary links, save raw materials, reduce costs, and make the processing, installation and production process follow the rules, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

Manufacturing and installing technology for combined flower pots capable of storing water, spraying and watering

InactiveCN108076895AGuarantee product qualitySave raw materialsWatering devicesCultivating equipmentsWater storageSurface cleaning

A manufacturing and installing technology for combined flower pots capable of storing water, spraying and watering is provided. A combined flower body is divided into a planting pot at the upper partand a water storage chamber at the lower part by a separator plate with drainage openings; the combined flower body is prepared by bonding soil, shaping and burning(or plastic cement compacting and molding); surface cleaning and grinding are performed; a water adding hopper is installed in the water storage chamber at one end of the flower pot opening; a watering device is installed on a support board at the opposite end of the water adding hopper; a suction pipe is connected with the watering device at the upper part and is inserted to the water storage chamber at the lower end; the installing firmness and leakage are checked; functional experiments are carried out. According to the manufacturing and installing technology for combined flower pots capable of storing water, spraying and watering, production and installation in accordance can be carried out orderly with the regulations, to ensure the quality and requirements of the manufacture of the products, to reduce irrelevant and unnecessary links, and to save raw materials, reduce costs, and to install and manufacture the production process in accordance with rules and regulations.

Owner:QINGDAO CENTURY YUNFAN IND

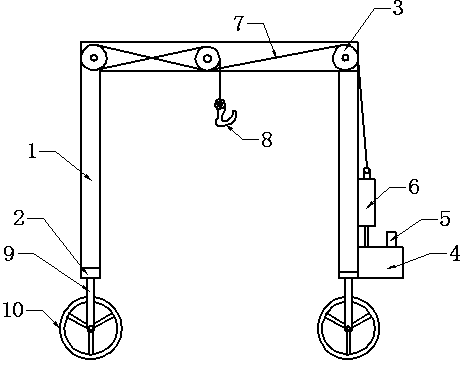

Manufacturing and installing process for hydraulic movable hanging bracket

InactiveCN108069355AGuarantee product qualitySave raw materialsPortable liftingFuel tankPulp and paper industry

The invention discloses a manufacturing and installing process for a hydraulic movable hanging bracket. The manufacturing and installing process comprises the following steps that a portal frame is welded by channel steel; wheel frames are welded to two ends of frame bottoms of the portal frame, and vertical wheel shafts and road wheels are installed on the wheel frames; a hydraulic oil tank witha hydraulic oil pump is installed at the right lower end of the portal frame; the hydraulic oil pump is connected with a hydraulic oil cylinder on the upper end of the oil tank through an oil pipe; three oil wire rope groove wheels are installed on the top end of the portal frame side by side, and an oil wire rope is hung on the oil wire rope groove wheels; a lifting hook is installed at the upperend of the oil wire rope, the lower end of the oil wire rope is fixedly connected with the upper part of the hydraulic oil cylinder; the whole surface is subjected to grinding, polishing and paint spraying; installed parts and the appearance are inspected; and a function test is carried out. According to the manufacturing and installing process for the hydraulic movable hanging bracket, orderly production and installation can be carried out according to specifications, so that the manufacturing quality and requirements of products are guaranteed, irrelevant and unnecessary links are reduced,meanwhile, raw materials can be saved, cost can be reduced, and the machining and installing process follows rules, and is safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

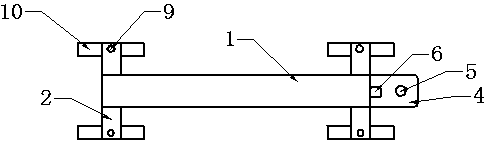

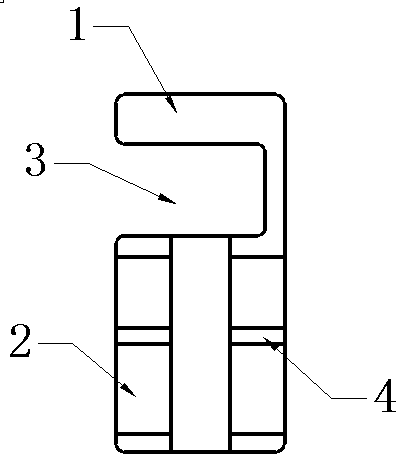

Separated-closed type multi-head stirring rod manufacturing and installation process

InactiveCN108057385AGuarantee product qualitySave raw materialsTransportation and packagingRotary stirring mixersPulp and paper industryManufacturing quality

A separated-combined type multi-head stirring rod manufacturing and installation process comprises that a grab handle, middle stirring rod and spherical stirring head integral blank, a right movable semicircle stirring rod blank with a right semicircle stirring head, and a left movable semicircle stirring rod blank with a left semicircle stirring head are casted from a stainless steel raw material; the surfaces of the grab handle, middle stirring rod and spherical stirring head integral blank, the right movable semicircle stirring rod blank with the right semicircle stirring head and the leftmovable semicircle stirring rod blank with the left semicircle stirring head have casting burrs removed and are polished; the upper ends of a middle stirring rod, the left movable semicircle stirringrod and the right movable semicircle stirring rod are bored and are subjected to finishing polishing; the upper end of the middle stirring rod 7 is mounted into a whole with the left movable semicircle stirring rod 2 and the right movable semicircle stirring rod 3 through a connection shaft 6; overall appearance inspection is performed; and manual experiments are performed. The separated-combinedtype multi-head stirring rod manufacturing and installation process can perform orderly production and installation according to the standard so as to ensure the manufacture quality and requirements of products, reduces unrelated and unnecessary links, can save the raw materials, and reduces the cost; the processing and installation production process observes all rules and regulations and is safeand orderly.

Owner:QINGDAO CENTURY YUNFAN IND

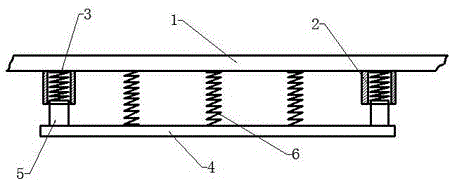

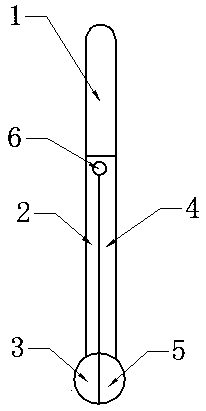

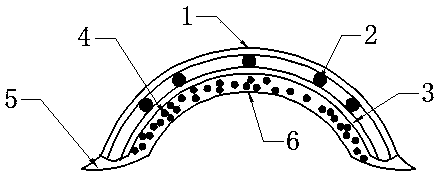

Shock absorbing helmet manufacturing and mounting technology

A shock absorbing helmet manufacturing and mounting technology comprises the steps as follows: plastic steel is selected and pressed into a top helmet and hard plastic is produced into a lining helmetblank piece through injection molding; the top helmet and the lining helmet are polished inside and outside; a helmet lining provided with a shock absorbing layer is produced from neutral sponge andcloth; the concave surface of the top helmet is connected with the top surface of the lining helmet through shock absorbing springs; the helmet lining provided with the shock absorbing layer is mounted in the concave surface of the lining helmet; overall inspection is performed; function tests are conducted. According to the shock absorbing helmet manufacturing and mounting technology, ordered production and mounting can be realized according to the specification, so that the manufacturing quality and requirements of products can be guaranteed, unrelated and unnecessary links can be reduced, raw materials can be saved, the cost can be reduced, and the machining, mounting and production process is standardized, safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

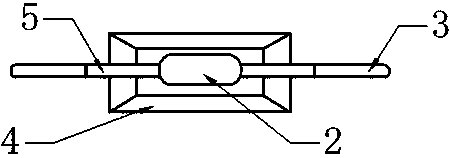

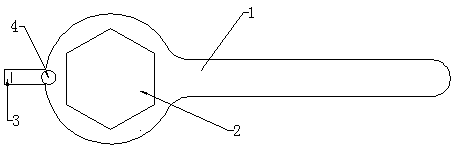

Manufacturing technology for key with inner hexagon wrench and screwdriver

InactiveCN108067820AGuarantee product qualitySave raw materialsKeysManufacturing technologyZinc alloys

The invention discloses a manufacturing technology for a key with an inner hexagon wrench and a screwdriver. A hexagon wrench, screwdriver and hanging ring key integrated blank is formed on a cold diecasting machine through pressing with a zinc alloy, integral burr removal is conducted, hexagon wrench, screwdriver and hanging ring correction is conducted, surface grinding, polishing, cleaning andphosphorization chroming are conducted, and surface and shape checking and function testing are conducted. According to the manufacturing technology for the key with the inner hexagon wrench and thescrewdriver, orderly production and installation can be conducted according to the standard, accordingly, the product manufacturing quality and requirement can be guaranteed, and unrelated and unnecessary links are reduced; the raw materials can be saved, cost is reduced, and the machining, installing and producing processes are kept on the rails and are safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

Manufacturing and installing process for rescue counterweight flash ball

InactiveCN108071960AGuarantee product qualitySave raw materialsElectric circuit arrangementsProtective devices for lightingManufacturing qualityEngineering

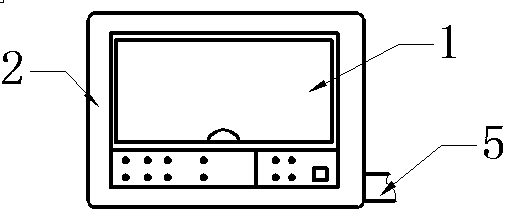

The invention discloses a manufacturing and installing process for a rescue counterweight flash ball. The manufacturing and installing process comprises the following steps that ABS is used for perform injection molding to form a fixed counter weight ball 3 internally embedded with fixing ribs 4 and an outer shell 1 with a tying rope ring 5 embedded outside; a transparent top shell 2 is formed byinjection molding of a colorless plastic raw material; the outer shell 1 and the top shell 2 is subjected to deburring and polishing; external threads is machined on outer shell 1, and internal threads is machined on the top shell 2; a light-emitting tube 7, a battery 8, a mercury contact intermittent switch 9 are assembled into a light-emitting body 6 on an assembling line; the light-emitting body 6 is installed in the top shell 2, and the inner threads of the top shell 2 are screwed and assembled tightly to the outer threads of the outer shell 1; whole inspection is carried out; and a function test is carried out. According to the manufacturing and installing process for the rescue counterweight flash ball, orderly production and installation can be carried out according to specifications, so that the manufacturing quality and requirements of products are guaranteed, irrelevant and unnecessary links are reduced, meanwhile, raw materials can be saved, cost can be reduced, and the machining and installing process follows rules, and is safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

Process for manufacturing and mounting simple solar water filling prompting devices

InactiveCN106813407AGuarantee product qualitySave raw materialsSolar heat devicesSolar thermal energy generationSolar waterBuoy

The invention discloses a process for manufacturing and mounting simple solar water filling prompting devices. The process includes arranging a partition plate which is not connected with the bottom of each water tank at a one-third location, which is close to an edge, of the water tank; extending solar water return pipes into the water tanks at two-thirds locations of the water tanks; arranging buoys with H-shaped sheet metal on the tops between the edges of the water tanks and the partition plates; mounting contact pieces and music electronic chips above the water tanks; connecting wires onto the sheet metal and connecting the sheet metal with the music electronic chips and the contact pieces. The process for manufacturing and mounting the simple solar water filling prompting devices has the advantages that the simple solar water filling prompting devices can be produced and mounted in order according to specifications, accordingly, the manufacturing quality of products can be guaranteed, requirements on the products can be assuredly met, and irrelevant and unnecessary links can be reduced; raw materials can be saved, the cost can be reduced, and machining, mounting and producing procedures follow conventional rules and regulations and are safe and ordered.

Owner:QINGDAO CENTURY YUNFAN IND

Manufacturing process for special-shaped semi-circular clamping locking clack special for rolling machine

The invention discloses a manufacturing process for a special-shaped semi-circular clamping locking clack special for a rolling machine. The process sequentially comprises the step that an aluminum-plastic raw material is placed at a hot-die casting machine to undergo die-casting to form a special-shaped semi-circular clamping locking clack blank; the internal stress is eliminated; die-cast burrs,sharp corners and excess materials are removed from the whole surface, and grinding is carried out; a semicircular cylinder and a convex edge are ground in a special mould; a clamping opening and a clamping clack are repaired; polishing, cleaning and phosphating are carried out integrally; plastic spraying is carried out; overall checking is carried out; and functional testing is carried out. According to the manufacturing process for the special-shaped semi-circular clamping locking clack special for the rolling machine, ordered production and installation can be carried out according to standards so that the manufacturing quality and requirements of the product can be guaranteed, irrelevant and unnecessary links are reduced, moreover, the raw material can be saved, the cost can be reduced, and the machining and installing production processes can observe all rules and regulations, and are safe and orderly.

Owner:QINGDAO MUGANG LIVESTOCK MACHINERY CO LTD

Fixed sunscreen cover manufacturing technology

InactiveCN108065473ASave materialGuarantee product qualityProtective garmentManufacturing technologyRespirator

The invention relates to a fixed sunscreen cover manufacturing technology. A fixed sunscreen cover is made from a sunscreen cloth which is high in air permeability and comfortable, the upper end is asunscreen mask, the middle is a sunscreen neck guard bar, the lower end is a fan-shaped sunscreen cloth, welting and locking are conducted, left and right hooks, child and mother buttons and left andright elastic fixing rings are customized, the left and right hooks are installed on the two sides of the sunscreen mask, the child and mother buttons are installed at the two ends of the sunscreen neck guard bar, the left and right elastic fixing rings are installed on the corners of the two ends of the fan-shaped sunscreen cloth, manual examination is conducted, and function testing is conducted. According to the fixed sunscreen cover manufacturing technology, orderly production and installation can be conducted according to specifications so as to ensure the product manufacturing quality and requirements, irrelevant and unnecessary links are reduced, the raw materials can be saved, the cost is lowered, and the processing and installing production process follows the rules and is safe and orderly.

Owner:QINGDAO CENTURY YUNFAN IND

Manufacturing and mounting process for brush with detergent

InactiveCN108056574AGuarantee product qualitySave raw materialsBrushesInjection molding machineMechanical engineering

Provided is a manufacturing and mounting process for a brush with a detergent. The process comprises: performing injection molding using ABS in an injection molding machine special special-purpose die, to form a brush body with brush, spray-holes, a detergent bin, and a detergent outlet pipe, and a sealing cap; cleaning burrs and dredging the spray-holes, the detergent outlet pipe, and the detergent bin of the brush body, and combing the brush; removing burrs on outer surfaces of the brush body and the sealing cap, and polishing; arranging a pushing valve in the detergent bin, an upper end ofthe brush body being provided with and connected with a pressing handle of the pushing valve, using the sealing cap to screw on a detergent bin mouth; checking an integrated mounting position and appearance; and performing function tests. The manufacturing and mounting process for a brush with a detergent can perform production mounting in order according to specifications, to ensure manufacturingquality and requirement of products and reduce unrelated and unnecessary steps. The process saves raw materials and reduces cost, and a processing mounting production process keeps on the rails and is safe and in order.

Owner:QINGDAO CENTURY YUNFAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com