Manufacturing process of profiling excavation glove

A production process and technology of gloves, applied in gloves, clothing, clothing, etc., can solve the problem of not guaranteeing product quality requirements and product functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

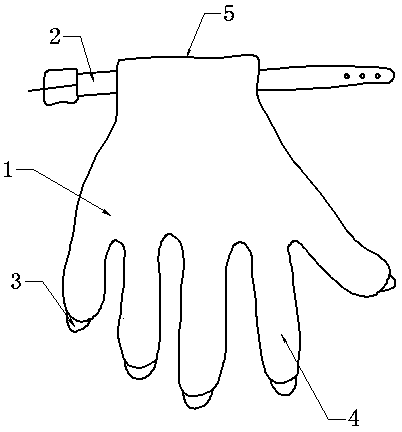

[0008] The present invention will be further described below in conjunction with the drawings.

[0009] Take profiling mining gloves as an example, select wear-resistant steel plates on the special mold on the punch press to stamp the city steel nails 3. Polishing, bluing treatment—put the steel nails 3 as inserts in the special glove injection mold—use wear-resistant steel nails , The rubber with good air permeability is made into the left and right profiling gloves with steel nails 3 in the special mold for glove injection with steel nails 3 inserts. 1—make the belt with leather 2. sew the belt 2. In the cuff 5—overall inspection—function test: Put the profiling glove 1 on your hand and fasten it with the strap 2, and the steel nail 3 will excavate the soil like a fingernail. It is qualified to achieve the above functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com