Manufacturing and installing process for cylindrical air-exhaust type mosquito killing device

An installation process and air-pumping technology, which is applied in the direction of capturing or killing insects, applications, animal husbandry, etc., can solve problems such as single production and manufacturing, inability to guarantee product quality and required product functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

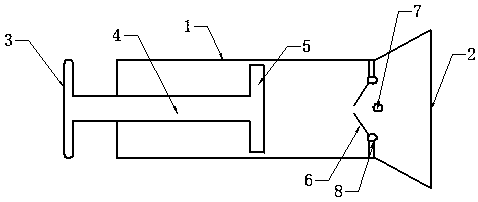

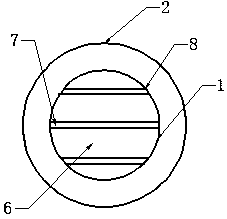

[0010] Taking the cylinder suction type mosquito trap as an example, the plastic raw material is used to injection mold in a custom-made mold to form a pumping tube 1 with a suction port 2, a pumping rod 4 and a pumping handle 3, and a one-way door 6. Blank parts - pumping tube 1, Drawing rod 4 and drawing handle 3 are integrated, the inner and outer surfaces of the one-way door 6 blank are deburred and polished, 4 sets of threads of the drawing rod—rubber pressed into piston 5, screw holes are drilled, deburred and trimmed—turning door stopper 7, door shaft 8 and combined Grinding, cleaning and galvanizing—put the piston 5 into the pumping tube 1 from the suction port 2 and hold the pumping handle 3, insert the pumping rod 4 from the upper end of the pumping tube 1 and tighten it with the threaded screw hole of the piston 5 in the pumping tube 1—in Suction port 2 installs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com