Manufacturing and installing technology for electric rotary beetling stick

An installation process and mallet technology, which is applied in the field of electric rotating mallet production and installation process, can solve problems such as product quality requirements and product functions that cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

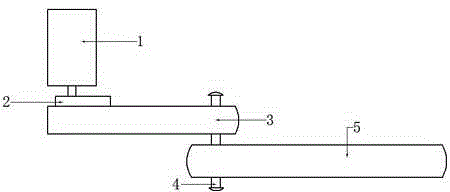

[0010] Take the electric rotating mallet as an example, accessories processing: turning eccentric wheel 2 with round steel, drilling - turning round steel turning rod 3, hammering rod 5, rotating shaft 4 - rotating rod 3, hammering rod 5, drilling - rotating rod 3. Deburring and polishing of the beating stick 5 and the surface of the rotating shaft 4; assembly: assemble the eccentric wheel 2 on the motor 1 shaft - install the rear end of the rotating stick 3 on the eccentric wheel 2 - connect the beating stick 5 with the rotating shaft 4 at the front end of the rotating stick 3 - Connection parts and appearance inspection, function test.

[0011] During the functional experiment, start the motor, and the rotation of the eccentric wheel 2 on the motor 1 shaft will bring the rotating stick 3 into a reciprocating motion of lifting and falling, so that the beating stick 5 can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com