Manufacturing technology of feeding cup fixed through two hooks

A manufacturing process and feeding technology, applied in the field of feeding cup manufacturing process, can solve problems such as single production and manufacturing, inability to guarantee product quality and product function requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

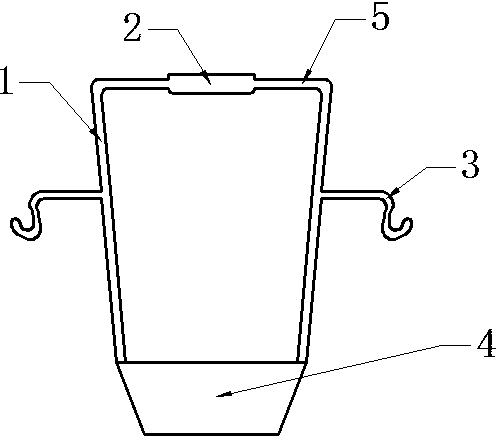

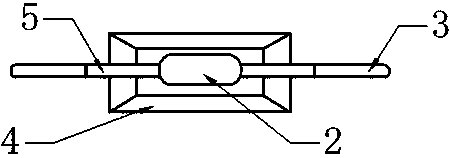

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] In the view, non-toxic plastic raw materials are used to injection mold the feed cup 4, the vertical bar 1 with the horizontal hook 3, the horizontal bar 5—the feed cup 4, the vertical bar 1 with the horizontal hook 3, and the surface of the horizontal bar 5 are deburred and polished— Use galvanized pipe to make hanging pipe 2, polish and spray paint—hanging pipe 2 is worn on cross bar 5—two ends of cross bar 5 are connected to upper end of vertical bar 1 by plastic welding—the lower end of vertical bar 1 is connected to upper end of feed cup 4 by plastic welding Along—cleaning the plastic welding joint, overall polishing—inspection, functional test: use the hanging tube 2 to connect the cup ring composed of horizontal and vertical rods 5 and 1 and the feed cup 4 with feed hanging on the feed conveying line to slide to the poultry feeding In the cage, catch the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com