Manufacture and installation process of dining table with garbage box

A technology of installation process and garbage box, which is applied in the field of catering round table manufacturing and installation process, can solve the problems of singleness of production and manufacturing, unable to guarantee product quality and require product functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

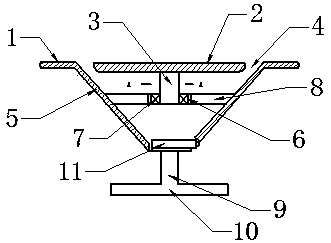

[0010] The present invention will be further described below in conjunction with accompanying drawing.

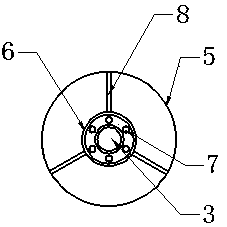

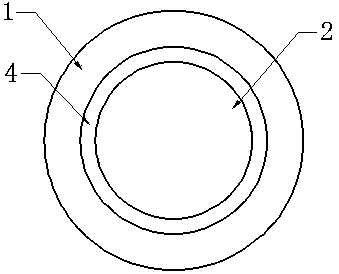

[0011] Take the dining round table table with garbage box as an example, install the bottom support shaft 9 at the center of the base 10 to fix the table body 5 with the side table 1—install the fixed support beam 8, the support bearing seat 6, and the installation bearing 7 under the center of the table body 5 1. Rotating support shaft 3—install and fix the center of the inner table 2 on the upper end of the rotating support shaft 3, and maintain a uniform isolation space between the inner table 2 and the side table 1. 4—install the garbage drawer 11 at the bottom of the table body 5—the overall surface And installation firmness inspection - function test: side table 1 places tableware, inner table 2 places dishes, inner table 2 rotates with the rotation of support shaft 3, bearing 7 can rotate arbitrarily for diners to eat dishes in different positions, The catering waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com