Manufacture and installation process of water-saving washing machine with storage tank

A technology of water-saving washing machine and installation process, which is applied to other washing machines, washing devices, textiles and papermaking, etc., and can solve the problems of single production and manufacturing, inability to guarantee product quality and required product functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

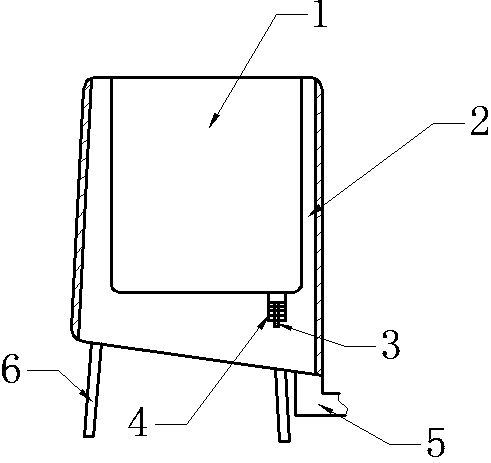

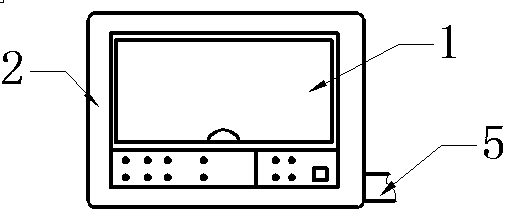

[0010] In the view, the water storage tank 2 blank corresponding to the outer dimension of the washing machine 1 is injection-molded with plastic in the mold of the large-scale injection molding machine—the water storage tank 2 blank is deburred, internally and externally polished—the water storage tank 2 is installed with a water storage tank valve 5, adjustable Outrigger 6—Install a one-way valve in the laundry drain valve 3 at the bottom of the washing machine 1—Install the washing machine 1 in the water storage tank 2 to seal the contact edge and fix it—Overall quality inspection—Functional test: When using, put the water in the washing machine 1 Put into the water storage tank 2 from the laundry drain valve 3, the one-way valve 4 can prevent the water in the water storage tank 2 from flowing back to the washing machine 1, and the adjustable legs 6 can adjust the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com