Manufacturing and installing process of spiral lever type mechanical crowbar

An installation process, lever-type technology, applied in the direction of crowbar, lifting device, etc., can solve the problems of single component, can not guarantee product quality and require product function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

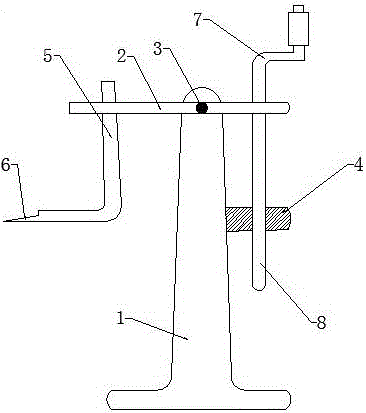

[0010] Taking the screw lever mechanical crowbar as an example, parts processing: ball milled iron casting base 1, fixed screw base 4 integrated, drilling fixed screw base 4 threads, drilling lever shaft 3 holes, overall surface grinding, rust removal, polishing, painting— Turning screw 8 and welding handle 7—forging adjustable pry bar 5 and warping head 6—turning lever shaft 3—forging lifting lever 2 and drilling lever shaft 3 holes and screw 8 screw holes; assembly: on the seat body 1. The top end is connected with the lever shaft 3 to the lifting lever 2—the lifting lever 2. The front end is fixed with a pry head 6. The adjustable prying rod 5—the lifting lever 2. The screw hole at the rear end is equipped with a screw 8 with a rocking handle 7, and the lower end of the screw 8 is screwed in Fixed screw seat 4 - connection part and appearance inspection, function test. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com