Assembly process of clothing rack with retractable hooks

An assembly process and a technology for hanging coat hooks, which are applied in the direction of manufacturing tools, wood processing appliances, etc., and can solve the problems of not guaranteeing product quality, requiring product functions, and the singleness of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

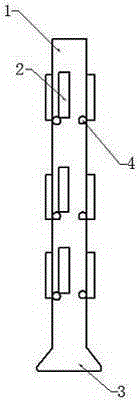

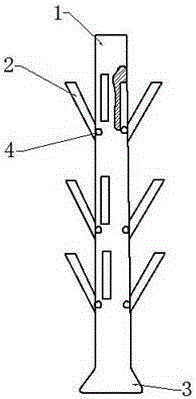

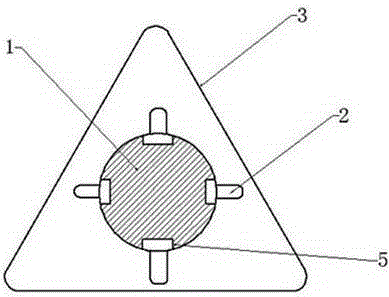

[0012] Taking the clothes hanger that can be put away by the clothes hook as an example, the wooden material is used to process the middle column 1 of the clothes hanger on the woodworking machine. N clothes hook slots 4 are processed from top to bottom in the four directions of the middle column 1 of the clothes hanger. Use instrument lathe to turn N wooden clothes hooks 2—the center column of clothes hanger 1, the surface of clothes hanger 2 is polished to remove processing burrs, polished with 300 mesh emery cloth, and the surface is coated with varnish—casting base 3, surface derusting and deburring, polishing, spraying Plastic—install the hanger center column 1 on the base 3—use metal bolts as the rotating shaft 5 and install the clothes hook 2 on the lower end of the clothes hook groove 4 of the hanger center column 1—each connection part and appearance inspection, fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com