Draught fan water curtain combination ventilation and cooling system assembling and debugging technology

A technology for ventilation and cooling, fan, applied in animal houses, poultry industry, poultry cages or houses, etc., can solve the problem of not guaranteeing product quality and requiring product functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

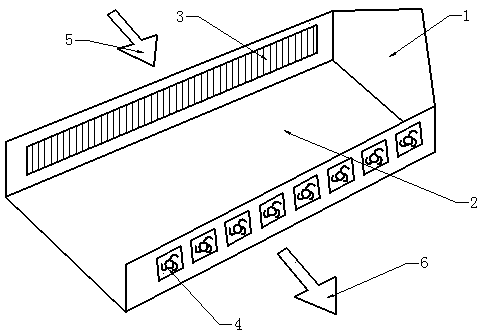

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] Taking the ventilation and cooling system combined with fan and water curtain as an example, a water filter curtain 3 is installed on the front wall of the ventilation space 2 of the poultry house 1, connected to circulating water—on the wall opposite to the front wall of the ventilation space 2 of the poultry house 1 Install N sets of one-way fans 4 corresponding to the water filter curtain 3 on the top—the corresponding adjustment of the water filter curtain 3 and the fan 4—determine the air inlet direction 5 and the air outlet direction 6; check the system operation, start the fan 4, and enter the ventilation space 2 from the air inlet direction 5 The wind energy is ventilated and cooled according to requirements, and then discharged from the air outlet direction 6 by the blower fan 4, and the water flow of the water curtain 3 can be adjusted to adjust the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com