Trap type rat trapping cage manufacture and installation process

An installation process and a technology for emptying squirrel cages, which are used in applications, animal traps, animal husbandry, etc., and can solve problems such as inability to guarantee product quality requirements and product functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

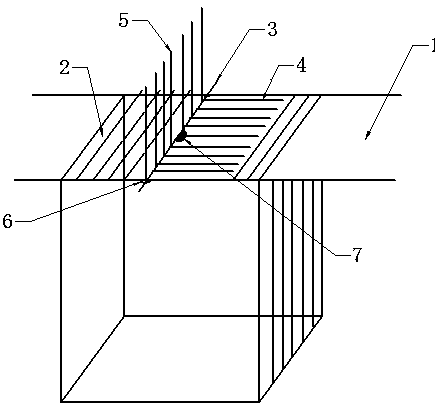

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] Take the trapping mouse cage as an example, the mouse trap 2 made of wire, the movable pedal 4 with the rotating shaft 3, the movable cover plate 5 are one-piece-install the bearing 6 on both sides of the upper plane of the mouse trap 2, place the The rotating shaft 3 of the movable pedal 4 and the movable cover 5 is installed on the bearing 6—the spring 8 is installed between the movable cover 5 and the edge of the mouse trap 2—at the angle between the movable pedal 4 and the movable cover 5 Install bait 7 at the midpoint—overall inspection—functional test: dig a suitable hole on the ground, put the mousetrap 2 down, the upper plane of the mousetrap 2 is flush with the ground surface 1, and the mice want to eat the bait 7 and move When the pedal 4 is on, the mouse's own weight overcomes the tension of the spring 8 and the movable pedal 4 promptly sinks in downwards,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com