Separated-closed type multi-head stirring rod manufacturing and installation process

An installation process and stirring rod technology, which is applied in the field of manufacturing and installation process of split-type multi-head stirring rods, can solve the problems of not ensuring product quality, requiring product functions, and single production and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

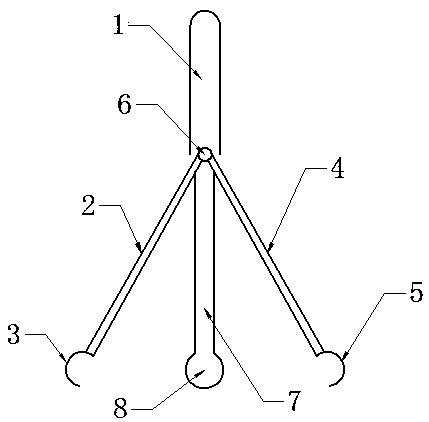

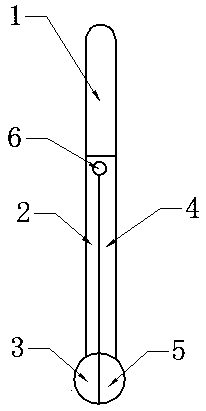

[0010] Taking the split multi-head stirring rod as an example, stainless steel raw materials are used to cast a handle 1, a middle stirring rod 7, a spherical stirring head 8, and a left and right movable semicircular stirring rod 2 with left and right semicircular stirring heads 4 and 5. , 3 Blank parts - handle 1, middle stirring rod 7, spherical stirring head 8 integrated blank and left and right movable semicircular stirring rods with left and right, semicircular stirring heads 4, 5 2, 3 Surface removal of casting burrs and polishing —Drilling and polishing the upper ends of middle stirring rod 7, left and right movable semicircular stirring rods 2 and 3—integrate the upper end of middle stirring rod 7 with connecting shaft 6 and left and right movable semicircular stirring rods 2 and 3—overall visual inspection —Manual experiment: choose one stirring head or separate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com