Manufacturing and installing process for hydraulic movable hanging bracket

A technology of mobile hanger and installation process, which is applied in hoisting devices, portable lifting devices, etc., and can solve the problems of single production, inability to guarantee product quality requirements and product functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

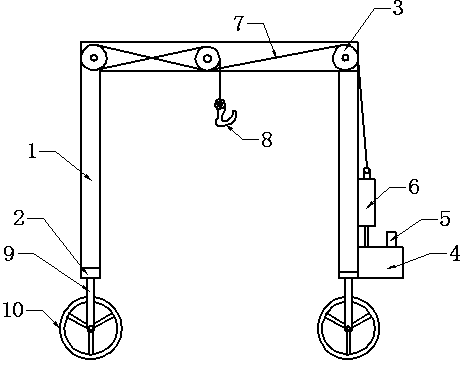

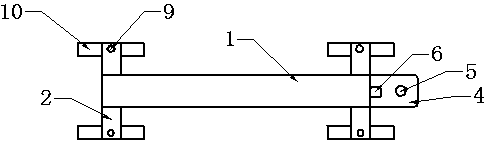

[0010] Take the hydraulic movable hanger as an example, weld the portal frame 1 with channel steel—weld the wheel frame 2 at both ends of the bottom of the portal frame 1, install the vertical wheel shaft 9, and the walking wheel 10—install at the lower right end of the portal frame 1 Hydraulic oil tank 4 with hydraulic oil pump 5—the hydraulic oil pump 5 is connected to the hydraulic oil cylinder 6 at the upper end of the hydraulic oil tank 4 with an oil pipe—three oil wire rope sheaves 3 are installed side by side on the top of the portal frame 1, and the oil wire rope 7 is connected - The hook 8 is installed on the upper end of the oil wire rope 7, and the lower end is connected and fixed to the hydraulic cylinder 6 - The overall surface is polished, polished, and painted - The installation part and appearance inspection - Functional test: connect the power supply of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com