Process for manufacturing and mounting simple solar water filling prompting devices

An installation process and solar energy technology, applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve problems such as inability to guarantee product quality requirements, product functions, and unitary components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

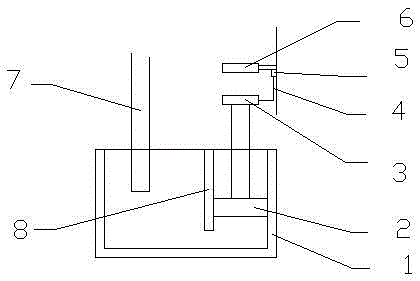

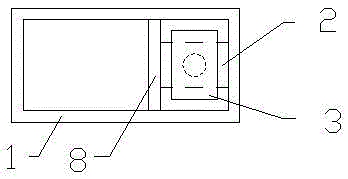

[0011] The present invention will be further described below in conjunction with the front view.

[0012] Take the simple solar energy water filling prompter as an example, install a partition 8 that is not connected to the bottom at one third of the water tank 1 - extend the solar return water pipe 7 into two thirds of the water tank 1 - connect it to the partition at the side of the water tank 1 Between the plates 8, the top is a metal sheet 3 I-shaped float 2—install the contact sheet 6 and the music electronic chip 5 above the water tank 1—connect the wire with the metal sheet 3 to connect the music electronic chip 5 and the contact sheet 6—conventional Inspection, function experiment.

[0013] During the functional experiment, first fix the contact piece 6 and the music electronic chip 5 on the wall according to the relative distance between the metal piece 3 on the float 2 in the water tank 1 and the contact piece 6, and then put some water into the water tank 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com