Manufacturing and mounting process for brush with detergent

An installation process and detergent technology, applied in the field of brush manufacturing and installation process, can solve the problems of single production and manufacturing, unable to guarantee product quality requirements and product functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

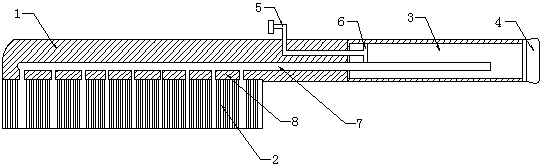

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] Taking the brush with detergent as an example, in the special mold of the injection molding machine, the brush body 1 with the brush 2, the injection hole 8, the cleaning agent chamber 3, the agent outlet pipe 7, and the sealing cap 4—a pair of brush bodies are injection-molded with ABS 1 spray hole 8, agent pipe 7, cleaning agent chamber 3 to clean burrs, dredge, comb brush 2—brush body 1, sealing cap 4 outer surface deburring, polishing—install push valve 6 in cleaning agent chamber 3 1. Install the hand pressure handle 5 connected to the push valve 6 on the upper end of the brush body 1. Screw the sealing cap 4 on the mouth of the cleaning agent chamber 3—Inspect the overall installation position and appearance—Functional test: first open the sealing cap of the cleaning agent chamber 3 4 Fill the cleaning agent chamber 3 with cleaning agent, cover the sealing cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com