Manufacturing and installing technology for rotating wheel inter-row weeder

An installation process and weeder technology, applied in the direction of weeding tools, hand tools, shovels, etc., can solve the problems that product quality requirements and product functions cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

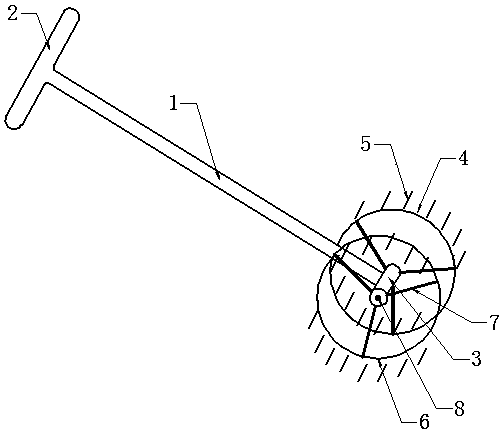

[0009] Take the wheel inter-spotting weeder as an example, use ordinary steel pipe to make the push rod 1 with handle 2, and polish it—weld the left and right hubs 6, 4 with auxiliary strip 7 and loose soil shovel 5 with steel bars and polish the appearance , carburizing treatment - turning axle 8, axle sleeve 3 and quenching, bluing - welding and installing axle sleeve 3 at the lower end of push rod 1, assembling axle 8 in axle sleeve 3 - installing left and right hubs 6 at both ends of axle 8, 4. The loosening shovel 5 on the fixed, left and right rotating wheels 6 and 4 is extended—overall inspection—functional test: hold the handle 2 push rod to push the left and right wheel hubs 6 and 4 to roll forward, and the loosening shovel 5 is enough It is qualified to loosen the soil between seedlings and weed and achieve the above functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com