Production assembling process for chair-to-bed transforming equipment

An assembly process and appliance technology, which can be applied to home appliances, beds, applications, etc., can solve the problems of inability to guarantee product quality, product functions, and component singleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

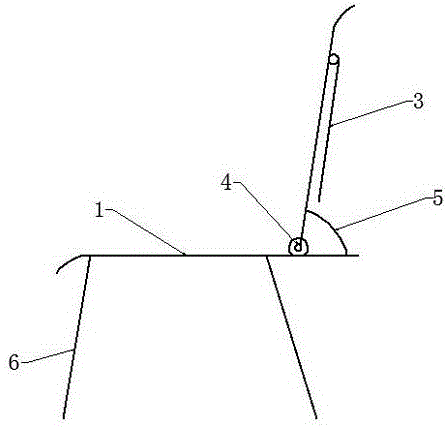

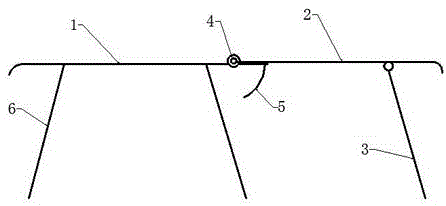

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] Take the chair and bed transformation tool as an example, choose wooden materials to process into seat board 1 and back board 2 to remove burrs on the surface - install fixed legs 6 on the bottom surface of seat board 1 - install movable legs 3 on the back of back board 2 - use rotating shaft 4 to move the back board 2 Connect to the rear end of the seat board 1—install a semicircular support 5 at the junction of the seat board 1 and the back board 2—polish and paint the outer surface—check the connection part and appearance, and perform functional experiments.

[0012] During the functional experiment, lift up the backboard 2, fold up the movable legs 3, hold the main semicircle support 5, it can be used as a seat, remove the semicircle support 5, lay down the backboard 2, and stretch out the movable legs 3, it can be used as a temporary If the bed is used, it is qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com