Improved band pulley feeding frame manufacturing and installing process

A technology of installation process and tool rest, which is applied in the field of manufacturing and installation process of tool rest with pulleys, can solve the problems of singleness of production and manufacturing, inability to guarantee product quality and required product functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

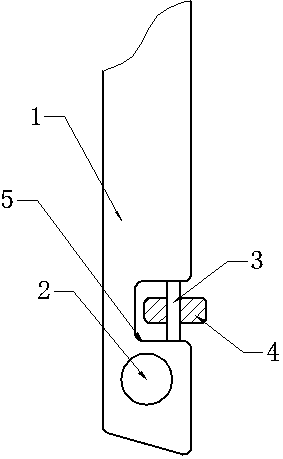

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] In the view, die-casting tool rest 1 blank with lead screw hole 2 and groove 5 is made of zinc alloy—deburring the outer surface of tool rest 1, drilling and tapping screw hole 2, repairing groove 5, drilling 3 holes on the vertical axis—the surface of the tool rest 1 is rust-removed and polished, cleaned and phosphated, and electrostatically sprayed—install the vertical shaft 3 with the runner 4 in the groove 5—install the screw hole 2 of the feeder 1 Installed on the lead screw—overall inspection—function test: the tool rest 1 moves axially with the rotation of the lead screw in the screw hole 2, and drives the runner 4 on the vertical shaft 3 in the groove 5 to rotate against the base to realize The above functions are qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com