Manufacturing and installation process for buffered fruit-receiving basket

An installation process and technology of fruit receiving baskets, applied in the field of fruit receiving basket manufacturing and installation technology, can solve the problems of single production and manufacturing, inability to guarantee product quality requirements and product functions, etc., and achieve the effect of easy-to-obtain materials and simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

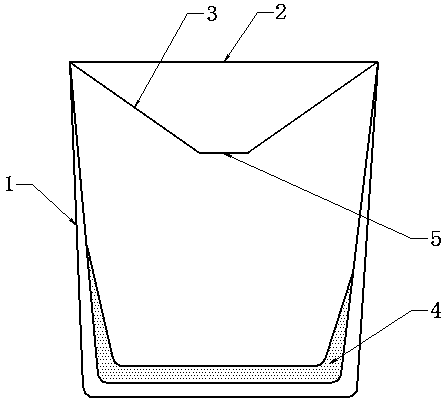

[0009] Take the fruit receiving basket with buffer as an example, weave the large basket mouth 2 with wicker, the fruit basket 1, weave the buffer net with the center of the fruit drop 5 in the cotton thread 3, and make the inner liner 4 made of plastic foam—lay the inner lining on the bottom of the fruit basket 1 Lining 4—Install the buffer net on the basket mouth 2 with the center of the falling fruit opening 5 3—Overall inspection—Functional test: Place the fruit basket 1 under the buffer tube of the fruit cutter, and the buffer net 3 can buffer the falling fruits into the Fruit basket, inner liner 4 supports fruit and does not injure pericarp, realizes above-mentioned function and is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com