Manufacturing process for special-shaped semi-circular clamping locking clack special for rolling machine

A manufacturing process and technology of rolling shutter machine, which is applied in the field of manufacturing process of special-shaped semicircular locking flaps for rolling shutter machines, and can solve problems such as inability to guarantee product quality and required product functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

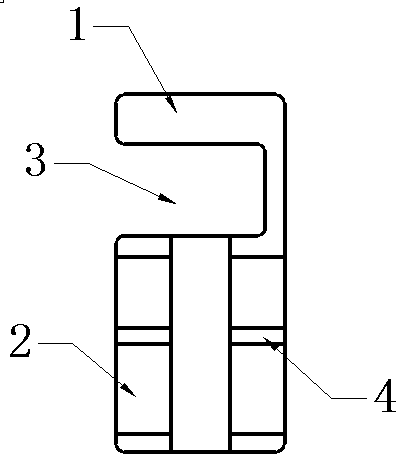

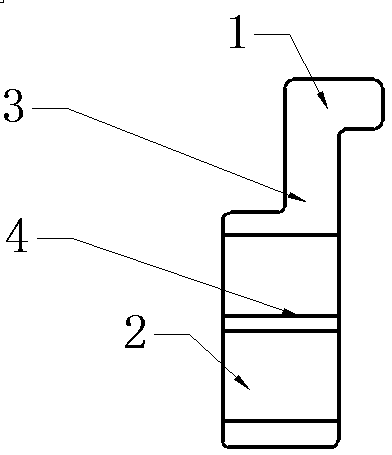

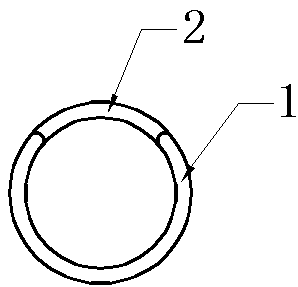

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Taking the special-shaped semi-circular locking valve for roller blinds as an example, the blank of the special-shaped semi-circular locking valve is die-casted on a hot die-casting machine using aluminum-plastic raw materials—eliminating internal stress—removing die-casting burrs, sharp corners, residual materials, and grinding on the entire surface. Grinding semi-circular cylinders and ribs in special molds—repair bayonets and flaps—overall polishing, cleaning, phosphating—plastic spraying—overall inspection—functional test: install special-shaped semicircular locking flaps on the rotating head of roller blinds On the top, the semi-cylinder is set on the rolling head, the convex ribs prevent falling off, the bayonet bites the curtain, and the bayonet can lock the curtain from being strung together. With the operation of the roller blind machine, the curtain is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com