Manufacturing and mounting process of power transmission tree well digging machine

A technology of power transmission and installation technology, which is applied in the directions of excavation/covering trenches, application, planting methods, etc., and can solve problems such as inability to guarantee product quality requirements, product functions, and unitary components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

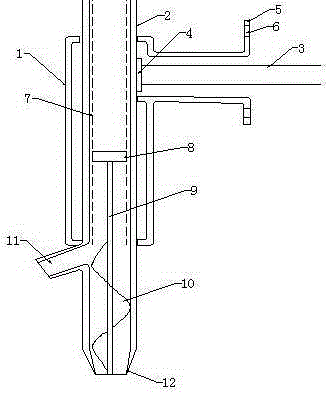

[0010] In the view, all parts are professionally manufactured and inspected to be assembled: install the power shaft 3 with the power turbine 4 in the upper horizontal body of the outer body 1—install the connecting screw hole 6 on the outer side of the horizontal body—the power connection plate 5—the vertical shaft of the outer body 1 A hollow worm 2 with an internal transmission thread 7 is installed in the body, and a soil discharge port 11 is installed outside the vertical body—the transmission gear 8 is mounted on the upper end of the transmission rod 9 with a spiral piece 10 and fastened into one body, and the overall installation is connected to the inner hollow worm 2 The top of the transmission thread 7, the bottom end of the helical piece 10 is flush with the excavation opening 12—each connection part, appearance inspection, function test—the outer surface is derus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com