Manufacturing process of special long-tooth egg outlet raker matched to egg collection belt

A manufacturing process and long-tooth technology, which is applied in the field of the manufacturing process of the special long-toothed egg scraper for egg-collecting belts, and can solve the problems that the product quality cannot be guaranteed and the product function is required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

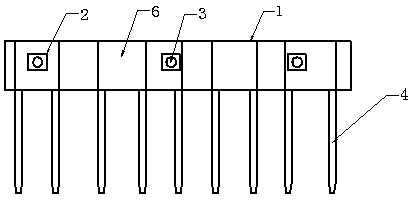

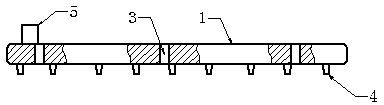

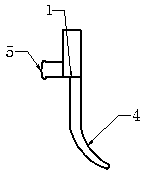

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Taking the special long-toothed egg-cooking belt supporting the egg-collecting belt as an example, the non-toxic plastic raw materials are used to inject and mold the fixed beam 1 with the stabilizing column 5 on the injection molding machine, and the egg-cooking teeth 4 are integrated blanks—quickly integrate them after being released from the mold. Put the pieces into the fixed cooling mould, and finalize the shape (keep the straightness of the fixed beam, that is, the consistency of the egg grill teeth)—after shaping, remove the mould, remove the burr, polish—drill the sink hole 2, drill the bolt hole 3—repair the egg slide 6, Egg Grilling Teeth 4, Stabilizing Nail Column 5—Overall Polishing, Inspection—Installation Experiment: Use the Stabilizing Nail Column 5 to align with the Stabilizing Nail Hole of the Rotating Shaft, and install the Fixed Beam 1 on the R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com