Manufacturing process for rotary automatic workpiece conveying grooved roller

A manufacturing process and automatic conveying technology, which is applied in the field of the manufacturing process of rotary automatic conveying workpiece groove rollers, can solve the problems that the product quality cannot be guaranteed, the product function and the singleness of the components are required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

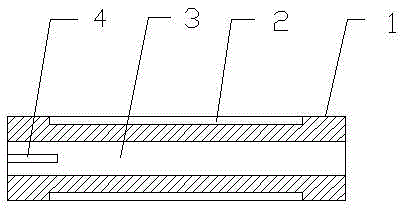

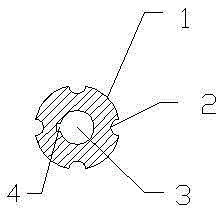

[0011] The present invention will be further described below in conjunction with the front view.

[0012] Taking the grooved roller for rotating and automatically transporting the workpiece as an example, cut the round steel of the corresponding length and turn the outer circle of the grooved roller on the lathe 1. Drill the shaft hole on the drilling machine. 3. Mill the key groove on the milling machine. Groove 2—grooved roller 1 surface, shaft hole 3 deburring, polishing—grooved roller 1 surface, shaft hole 3 chrome plating—appearance inspection, function test.

[0013] Functional experiment, first pass the circular shaft hole 3 on the delivery grooved roller 1 through the motor shaft, fix it on the motor through the keyway 4 with a fixed key, turn on the motor switch and the delivery grooved roller 1 will automatically rotate, the screw and the polished rod pass When sending part grooved roller 1, it will flow into sending part grooved roller 1 groove 2 li, one by one the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com