Self-return planar three-degree-of-freedom floating supporting mechanism

A technology of automatic return and floating support, applied in workbenches, hand-held tools, manufacturing tools, etc., can solve the problems of difficult control and difficult assembly of the carrier platform, and achieve the effect of precise docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

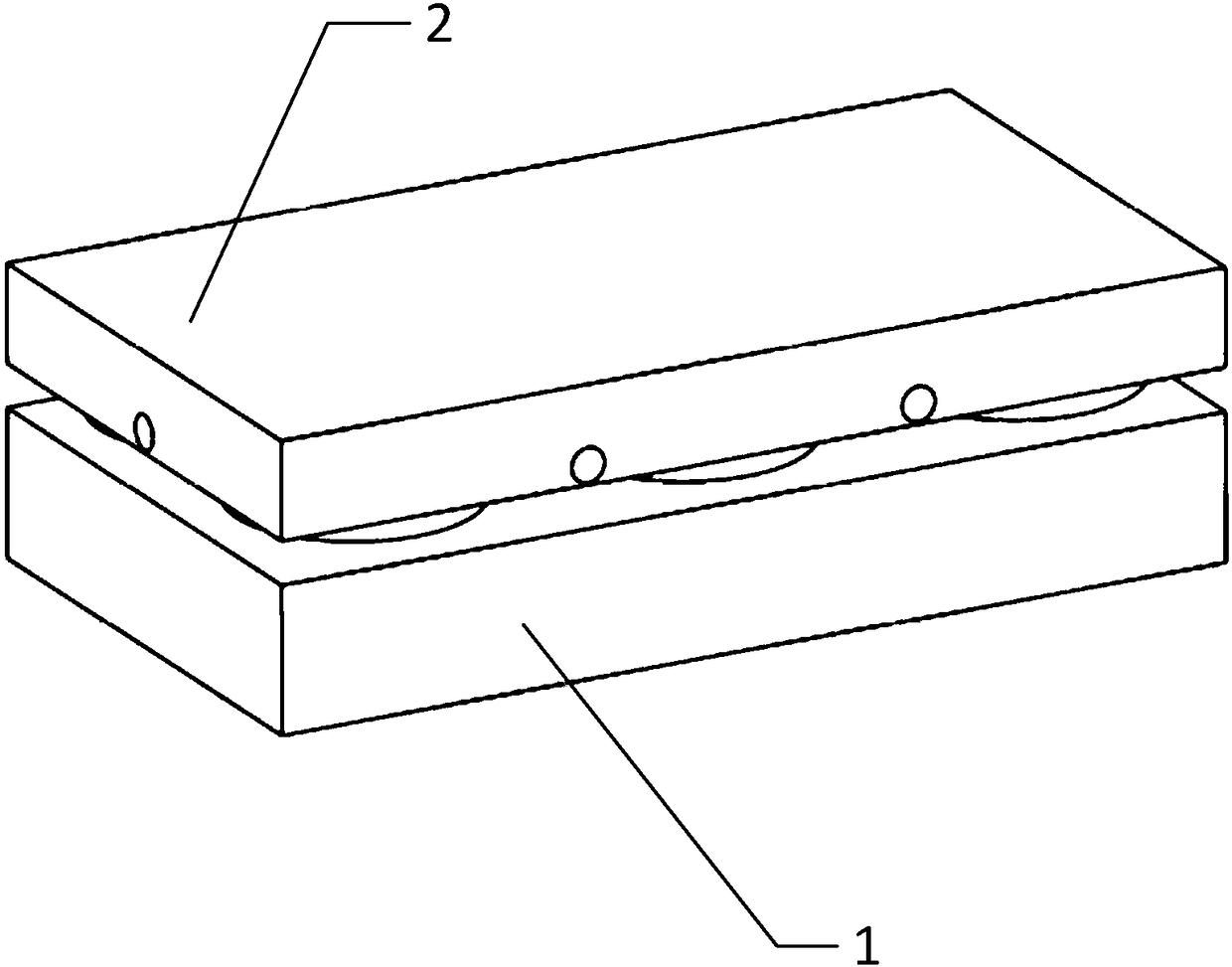

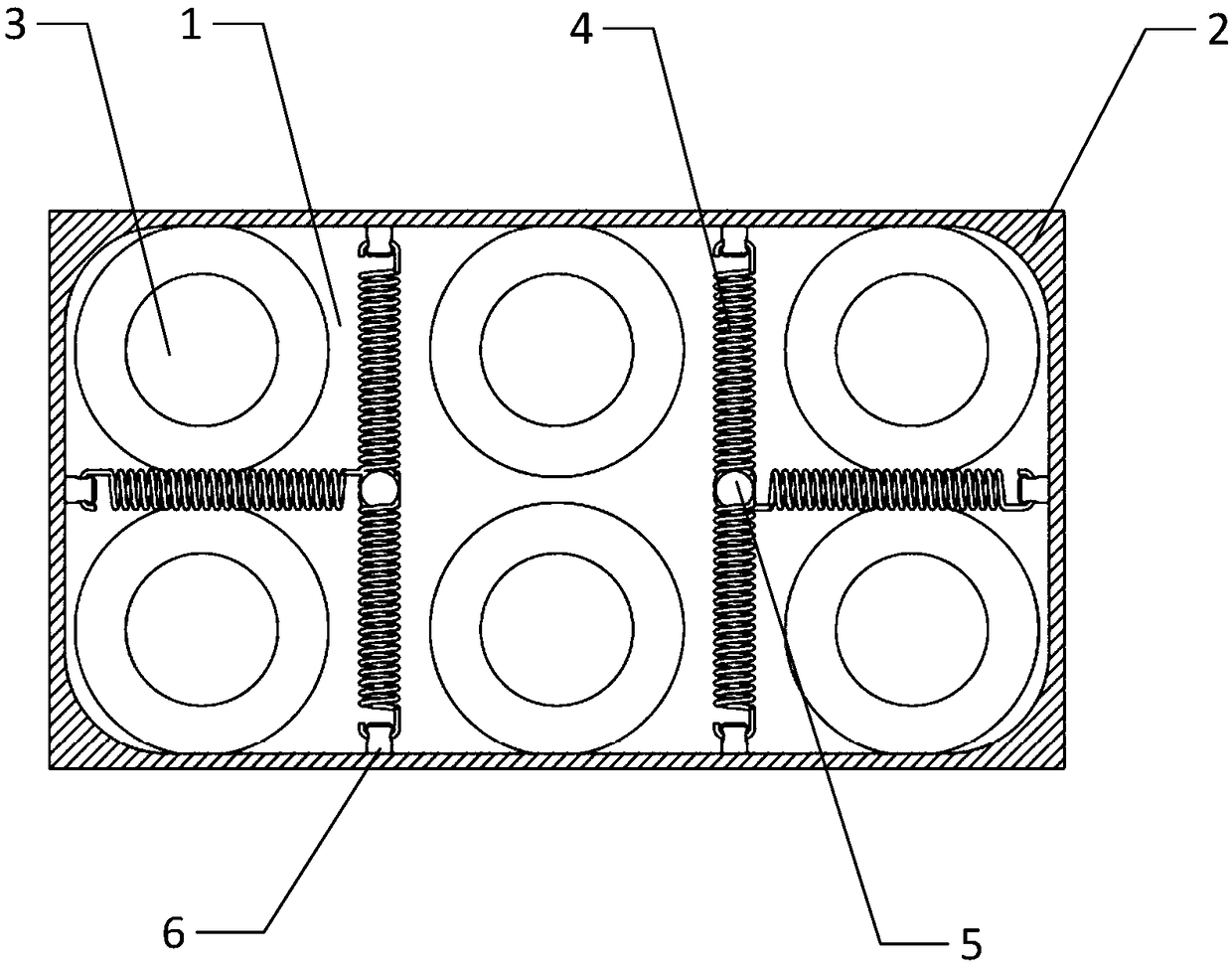

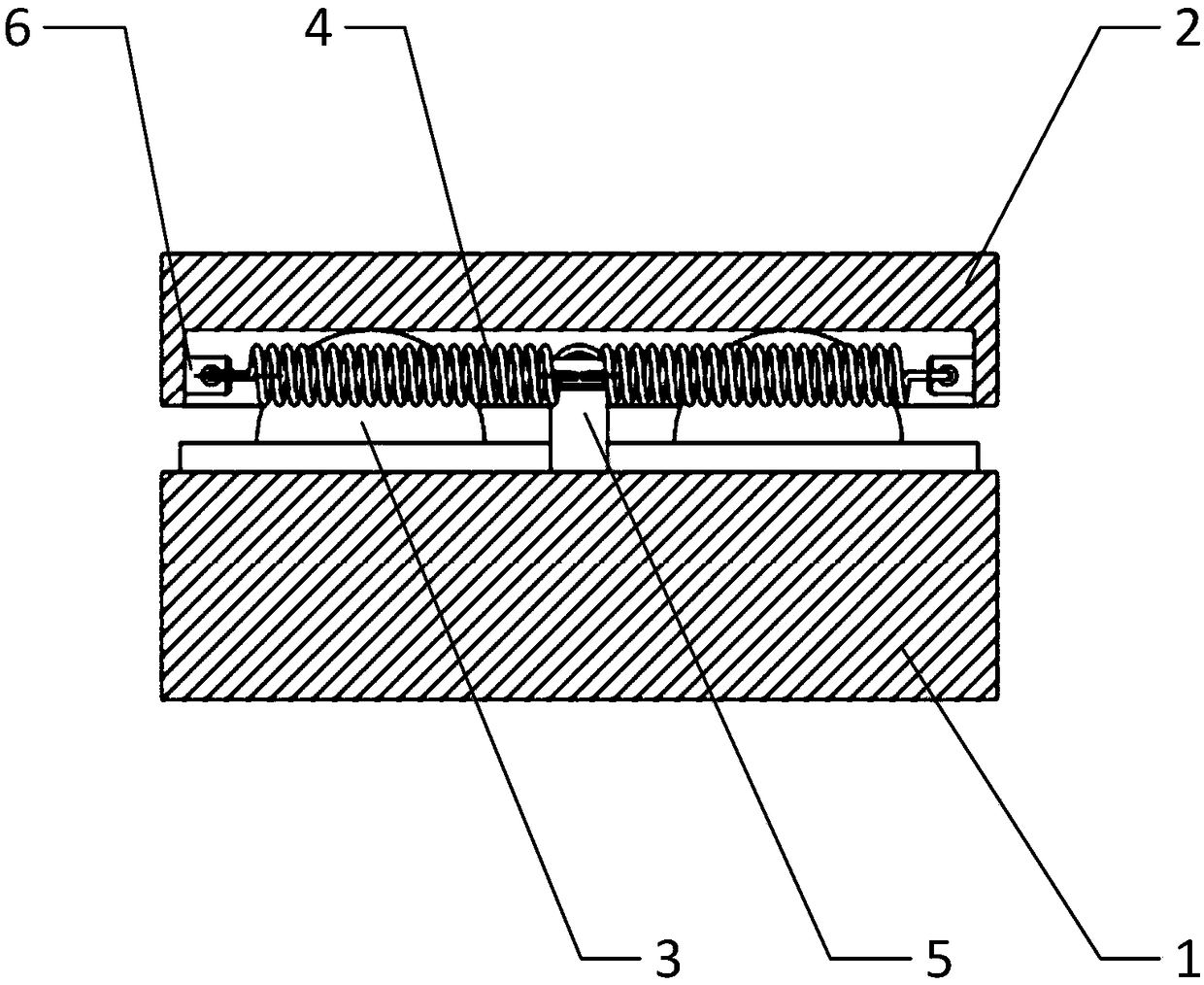

[0017] An automatic return three-degree-of-freedom floating support mechanism of the present invention is as attached Figure 1 to Figure 3 As shown, it includes a base 1, a floating platform 2, a sliding ball 3, a spring 4, a vertical fixed block 5 and a horizontal fixed block 6. There are multiple spherical grooves on the base 1 and six sliding balls 3 are installed. The floating platform 2 rides on the six sliding balls 3 to form a spherical pair, so the floating platform 2 can slide and rotate horizontally relative to the base 1 . Six springs 4 are used to connect the base 1 and the floating platform 2, two vertical fixed blocks 5 are fixed on the base 1, the base 1 is rectangular, and the two vertical fixed blocks...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap