Double-driving double-bridge table changing station-based double-workpiece table high-accuracy exchange device

A technology of double workpiece table and exchange device, which is applied to the exposure device of photoengraving process, photoengraving process of pattern surface, optics, etc., can solve the problem of shortening response time and positioning stabilization time, appearing torque and reducing system reliability and other problems to achieve the effect of shortening the positioning stabilization time, reducing the volume and inertia, and improving the scanning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

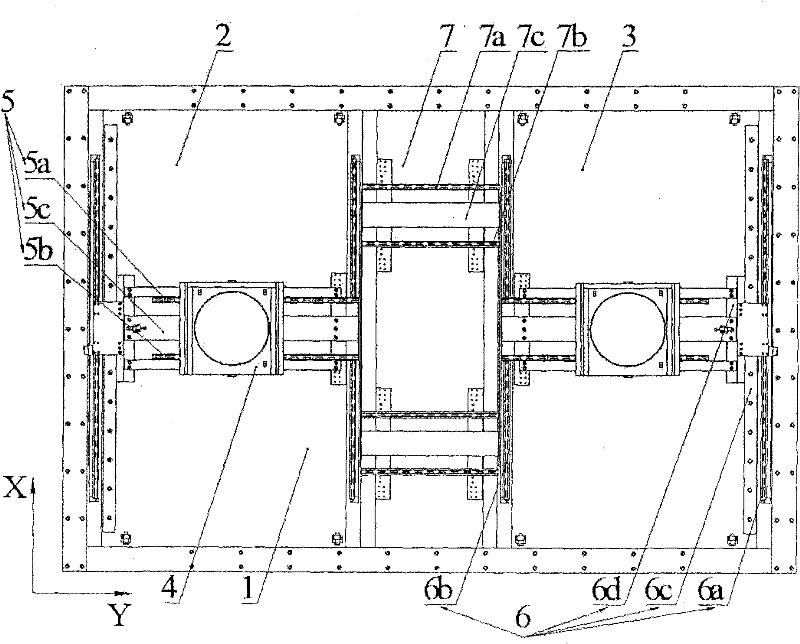

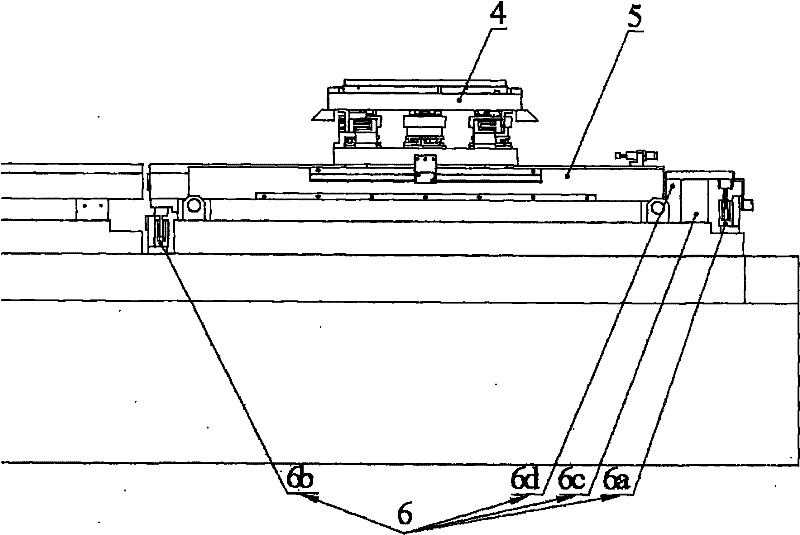

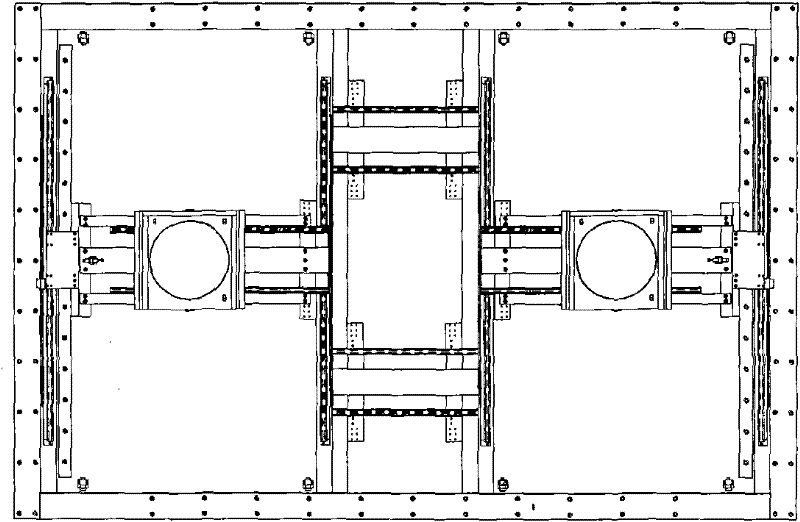

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] A high-precision exchange device for double workpiece tables based on double-drive double-bridge table-changing stations, the device includes an exposure station 2 and a pretreatment station 3, and the mechanical structures of the exposure station 2 and the pretreatment station 3 include The silicon wafer stage 4 arranged symmetrically on the left and right sides of the base 1, the Y-direction U-shaped groove type first linear motor 5a, the Y-direction U-shaped groove type second linear motor 5b, and the Y-direction static pressure air bearing guide rail 5c The two Y-direction long-stroke linear motion units 5 consist of an X-direction U-shaped groove-type first linear motor 6a, an X-direction U-shaped groove-type second linear motor 6b, an X-direction static pressure air bearing guide rail 6c and a Y-direction Two X-direction long-stroke linear motion units 6 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap