A disc motor

A disc motor and sub-disc technology, which is applied to electromechanical devices, electrical components, electric components, etc., can solve the problems of large weight, low power density, and difficult processing of disc motors, avoid metal corrosion, and improve power density. , Overcome the effect of harmonics and cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

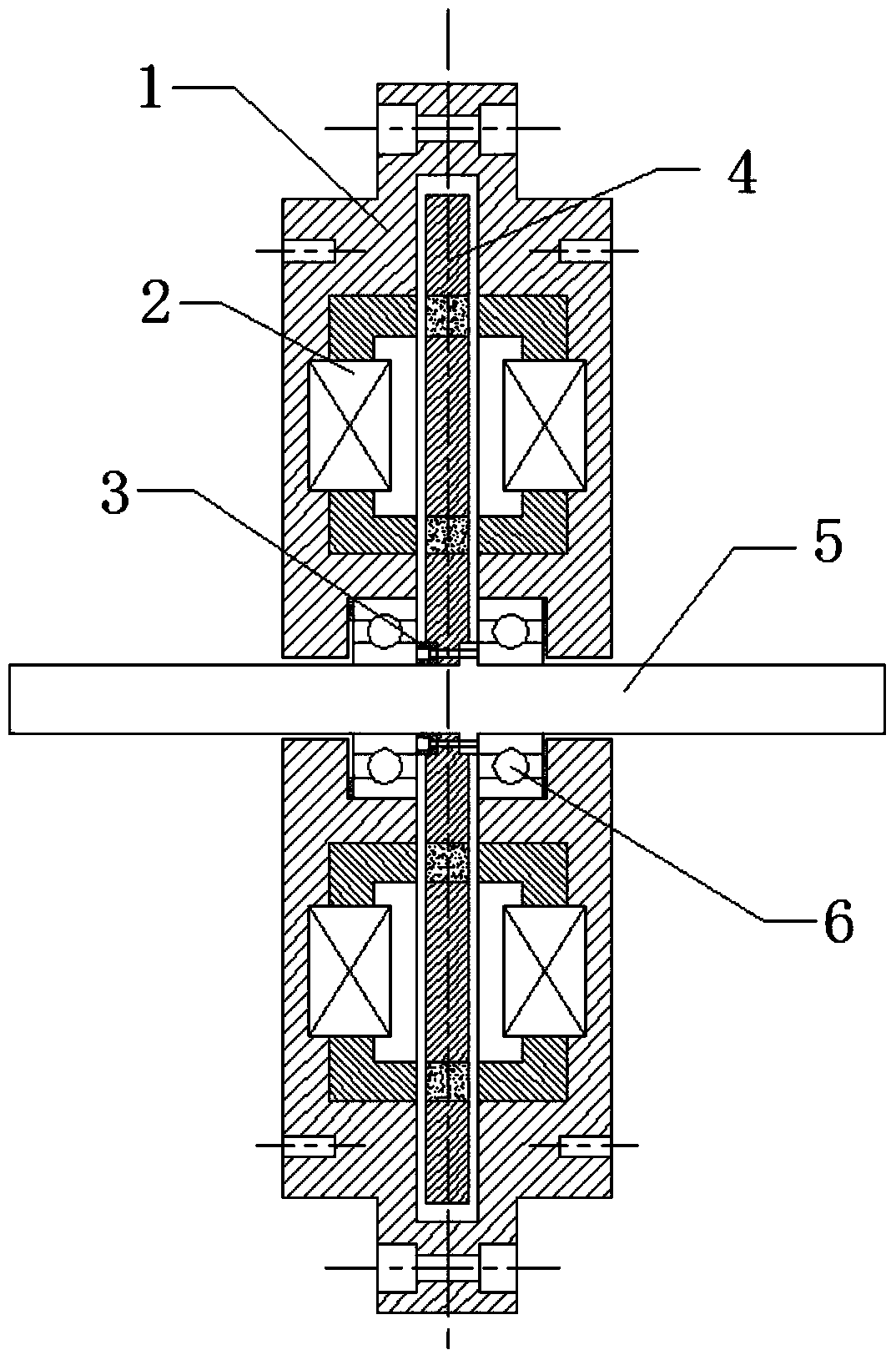

[0034] Such as figure 1 As shown, the disc motor of the present invention includes a stator disc 1 , a stator core 2 , a rotor disc 4 , a rotating shaft 5 , a fixed disc 3 and a bearing 6 . The rotor disk 4 is located between the two stator disks 1 and is fixed to the rotating shaft 5 through the fixed disk 3 .

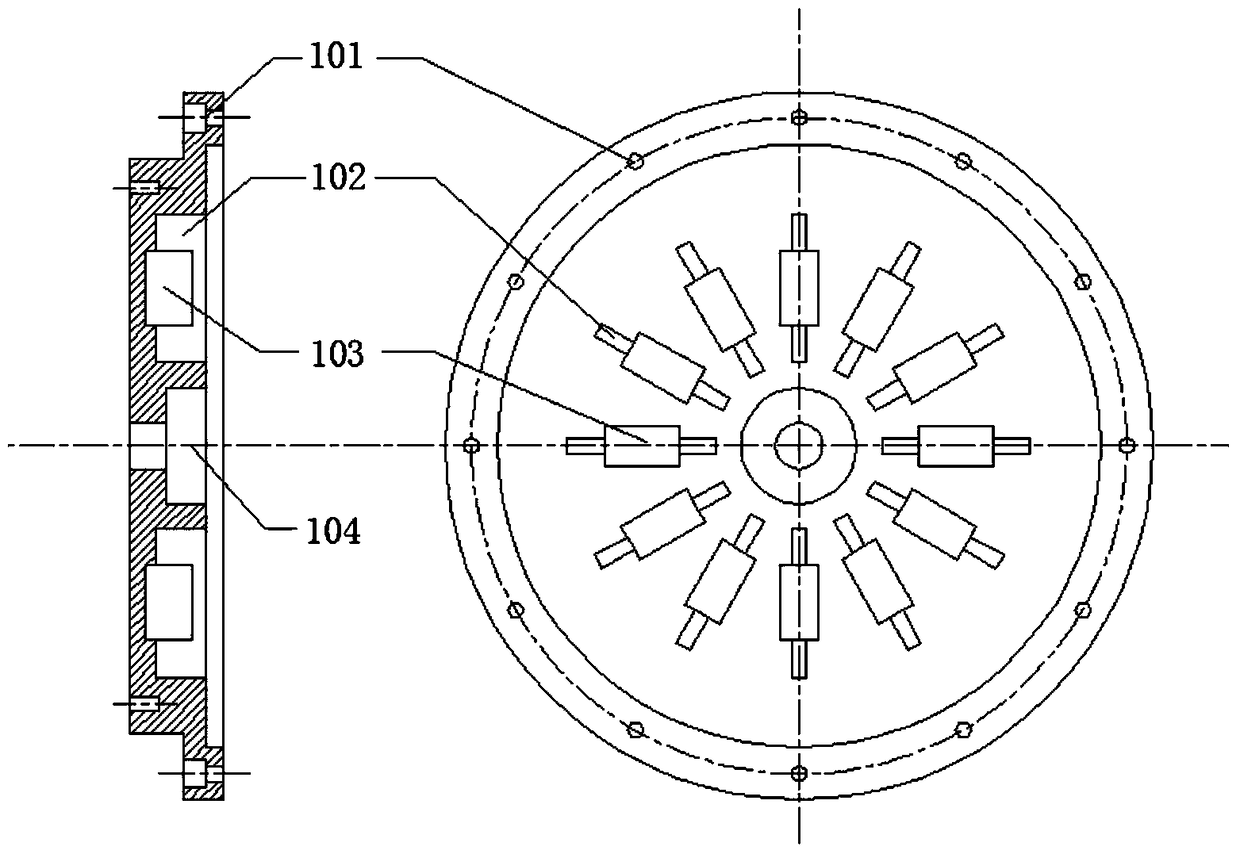

[0035] Such as figure 1 or figure 2 or Figure 4 As shown, "U"-shaped silicon steel sheets are laminated to form a "U"-shaped iron core 201 with a certain thickness, and a winding coil 202 is wound in the middle of the "U"-shaped iron core 201 to form a stator core 2 . The stator core 2 is embedded in the groove inside the stator disk 1 , the "U" shaped core 201 corresponds to the narrow groove 102 , and the winding coil 202 corresponds to the wide groove 103 .

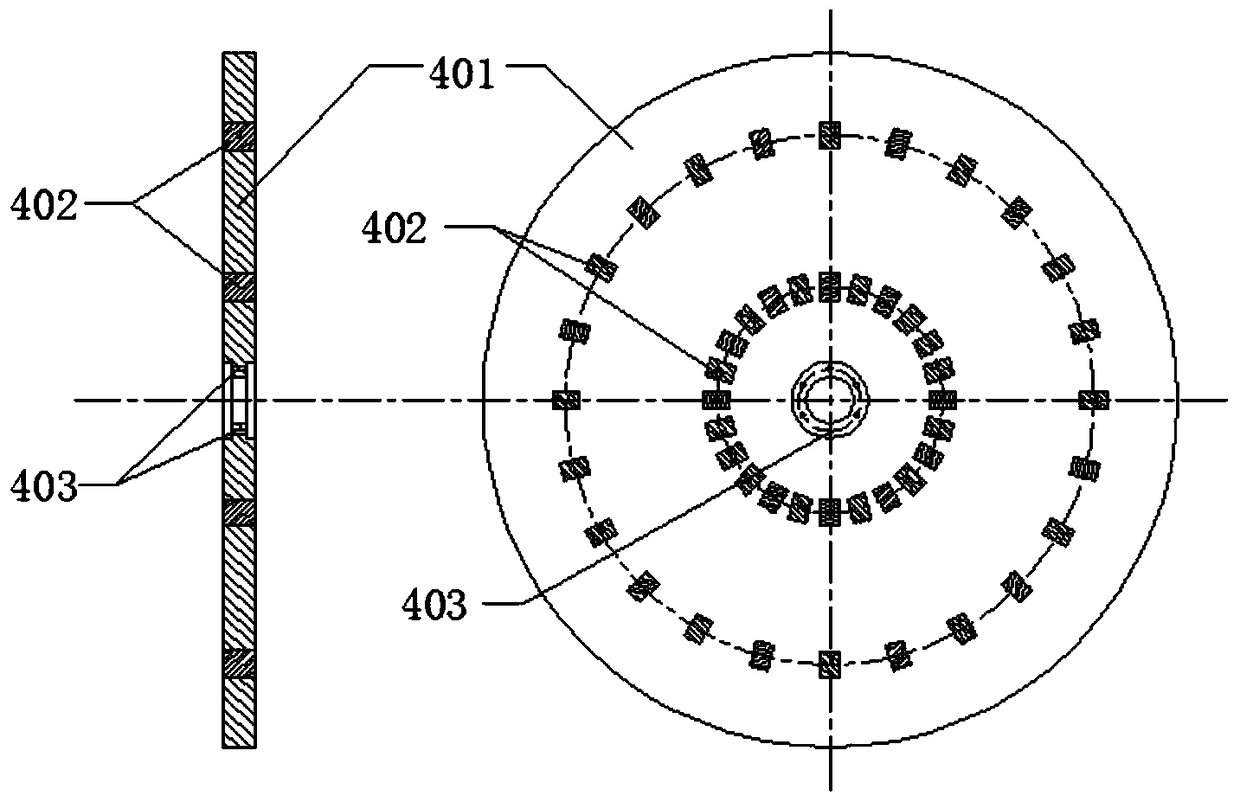

[0036] Such as figure 1 or image 3 or Figure 5 or Figure 6 A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap