A bronzing device

A bronzing paper and plunger technology, applied in transportation and packaging, printing, printing presses, etc., can solve the problems of low work efficiency, high equipment cost, high labor cost, reduce equipment cost, simplify structure, and avoid scattered Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

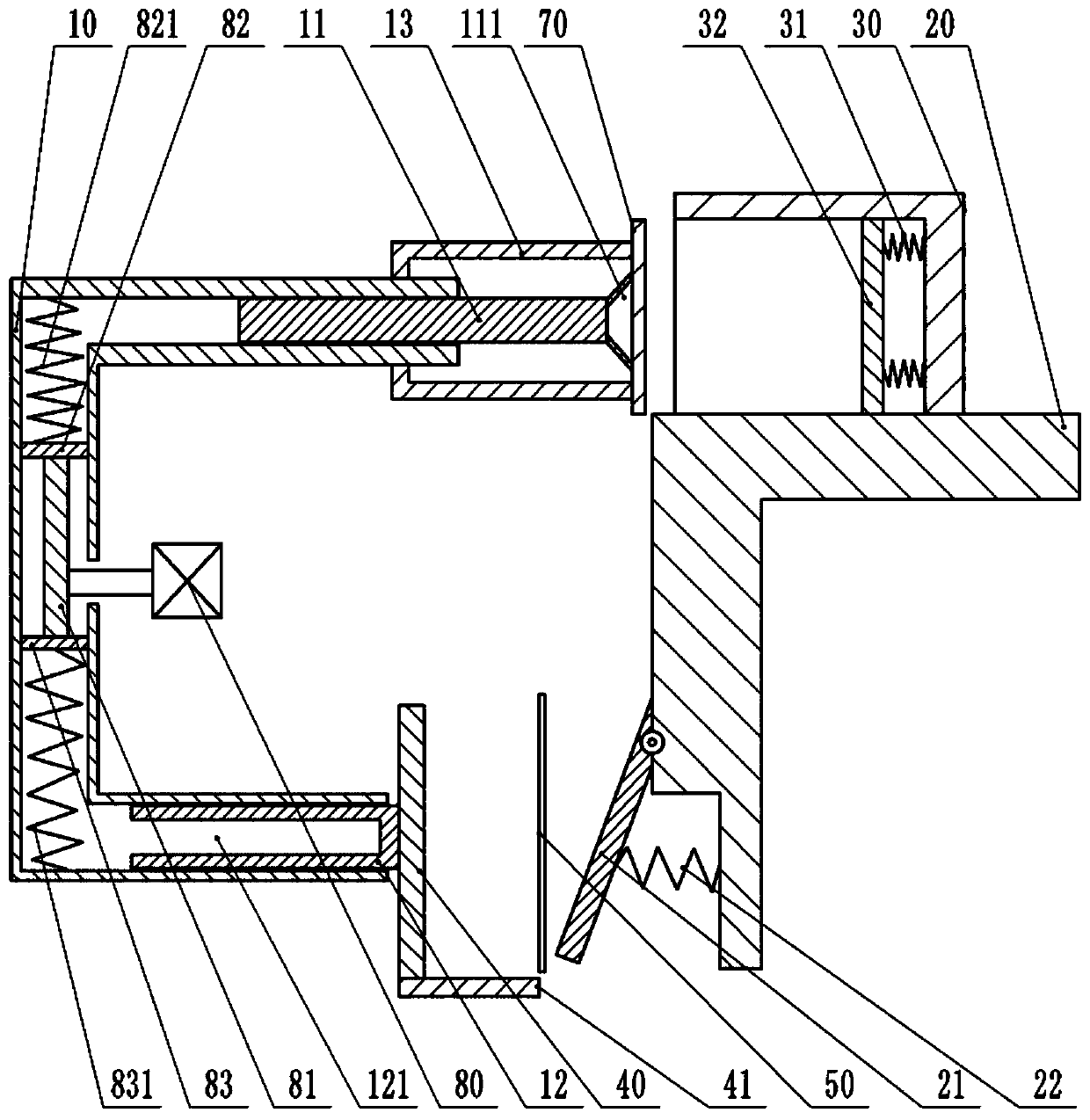

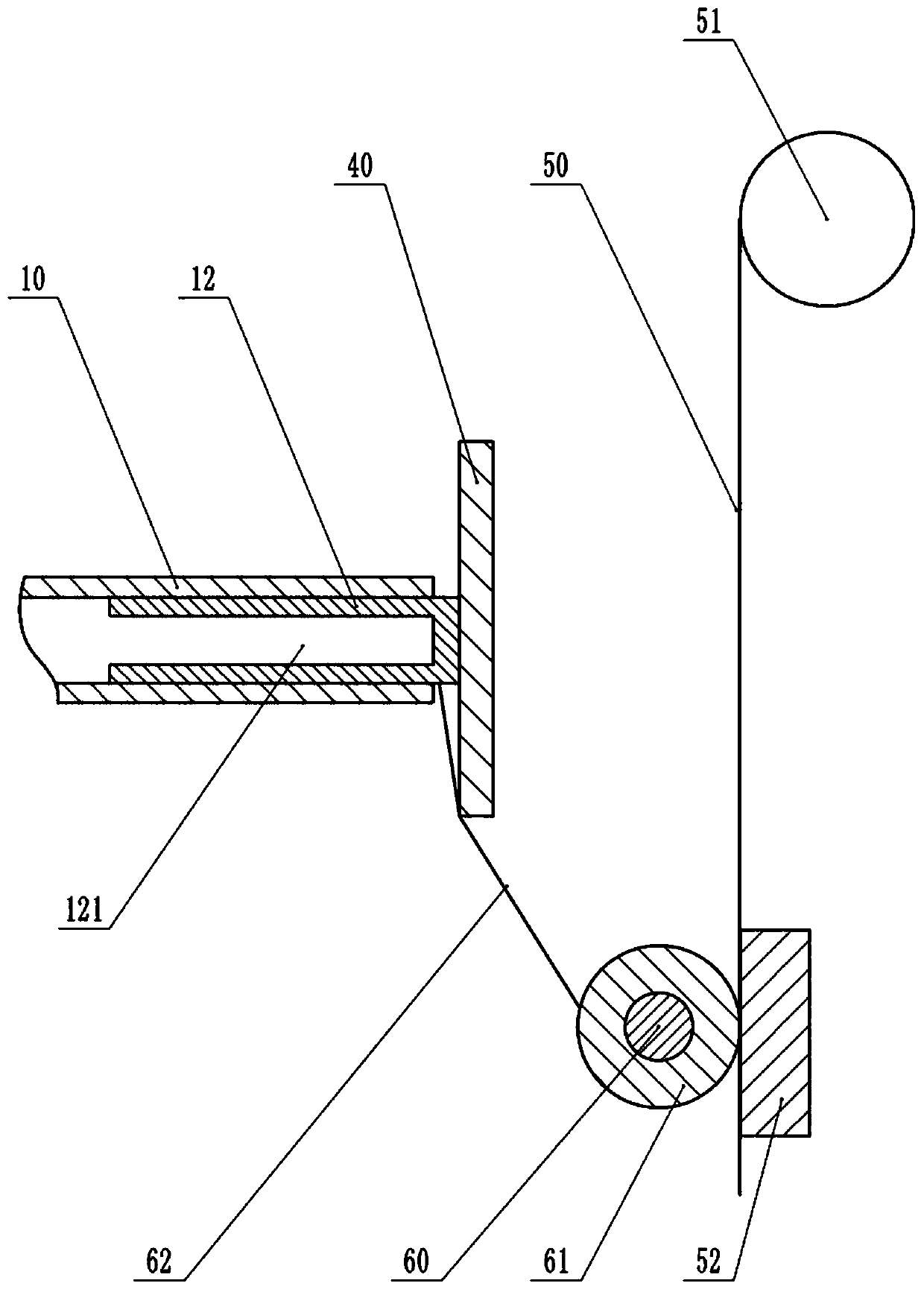

[0019] Instructions attached Figures 1 to 2 The reference signs in include: connecting column 10, first plunger 11, suction cup 111, second plunger 12, concave cavity 121, ejector rod 13, frame 20, pressing plate 21, elastic member 22, storage box 30, Spring 31, push plate 32, platen 40, receiving plate 41, bronzing paper 50, unwinding roller 51, support plate 52, rotating shaft 60, paper feed roller 61, pull cord 62, workpiece 70, motor 80, cam 81, the first A piston 82, a first extension spring 821, a second piston 83, and a second extension spring 831.

[0020] Such as figure 1 As shown, a bronzing device includes a suction unit, a pressing unit, a placing unit, a power unit, a paper feeding unit and a communication column 10 with a C-shaped longitudinal section. The suction unit includes a first plunger 11, a suction cup 111 and a plurality of ejector rods 13 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com