Horizontal battery charging method

A horizontal battery, acid filling technology, applied in the direction of lead-acid battery, battery pack parts, lead-acid battery construction, etc., can solve problems such as leakage and affecting the normal use of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

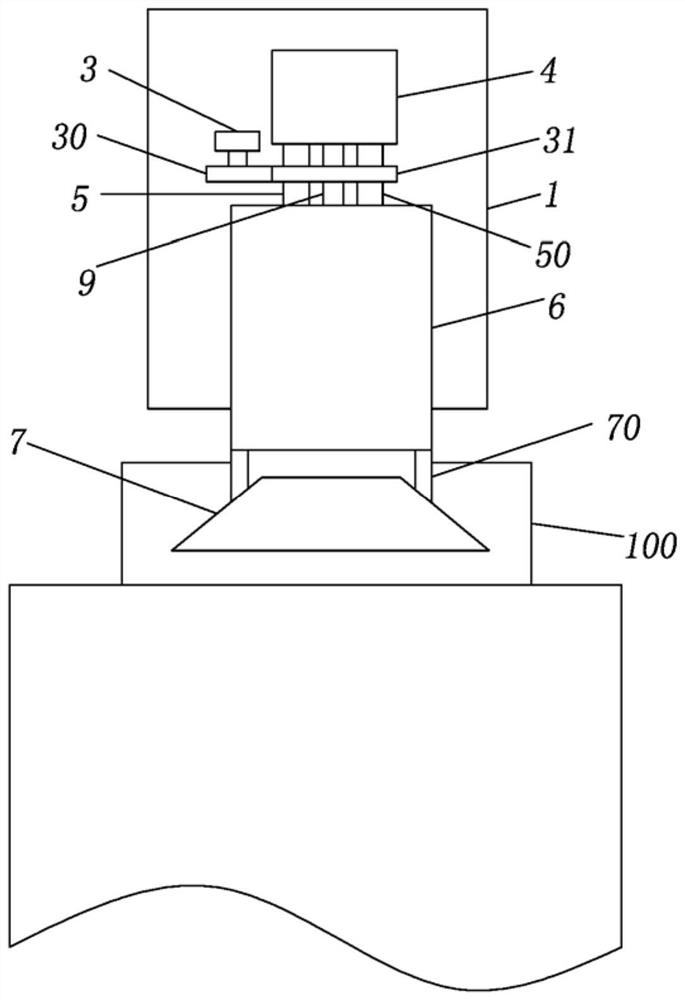

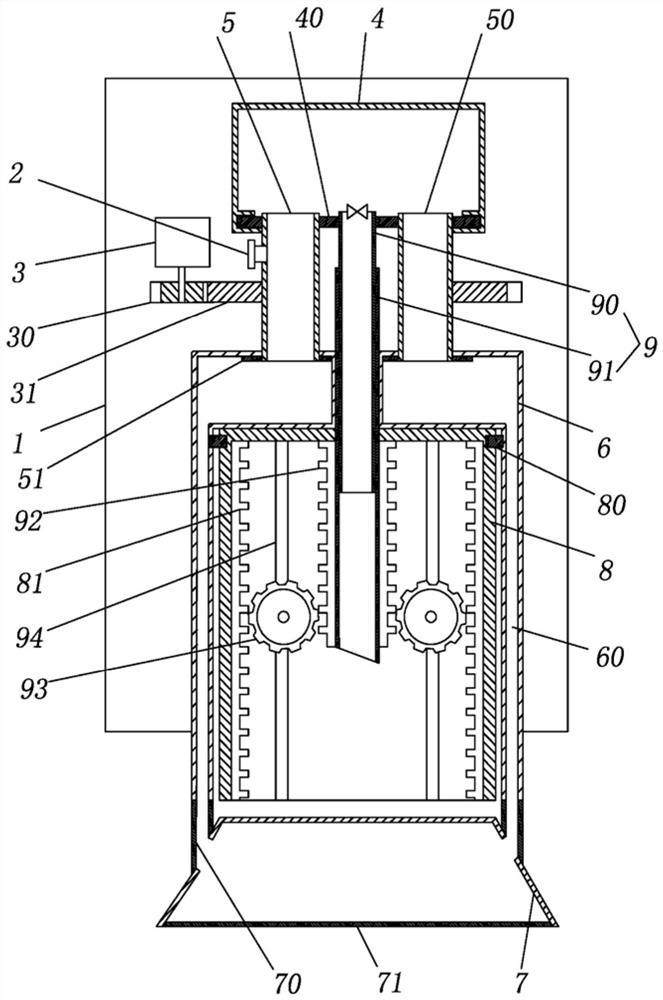

[0027] A method for filling acid into a horizontal battery, comprising the following steps:

[0028] Step 1, preparation of electrolyte: add pure sulfuric acid to distilled water and mix to obtain a concentration of 1.2g / cm 3 electrolyte, and reduce the temperature of the electrolyte to 15°C.

[0029] Step 2: Vacuumize the battery: Use an air pump to pump out the air inside the battery, and use a vacuum detector to check whether the vacuum of the battery is below 0.2 MPa. If yes, go to step 3. If not, continue to vacuum.

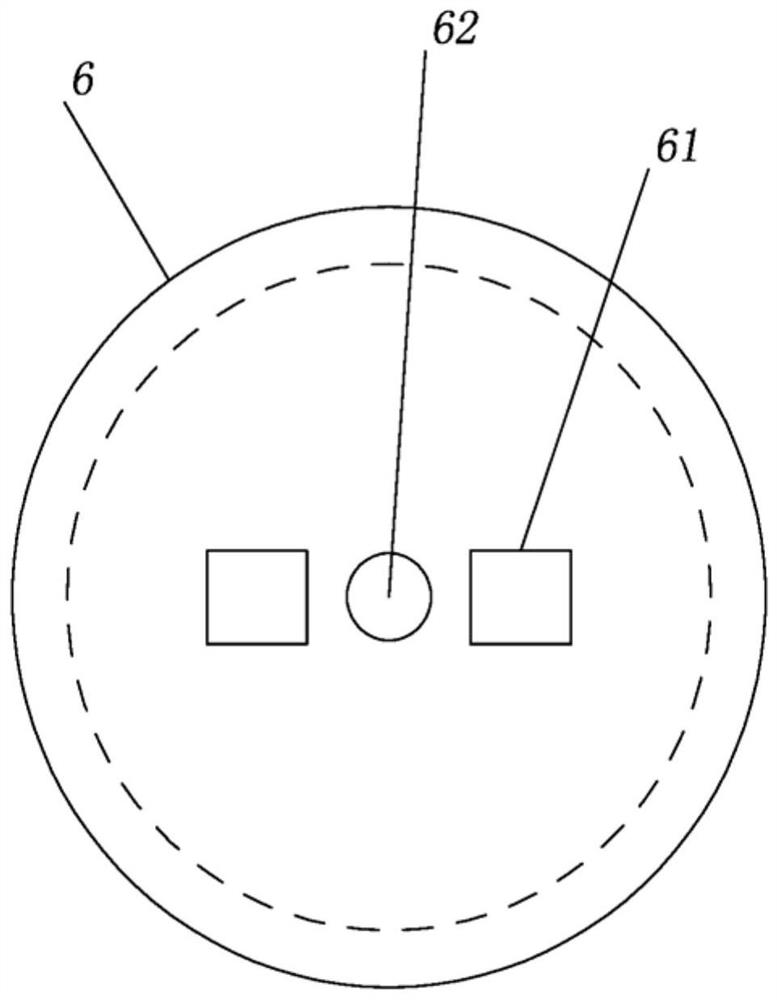

[0030] Step 3, acid filling: put the electrolyte in step 1 into the electrolyte tank 4, and then lead it to the liquid distribution part 7 with the acid filling pipe 9 while stirring, and the liquid distribution part 7 rotates and throws out the electrolyte to the battery Medium; the stirring speed of the electrolyte is 100r / min.

[0031] Step 4, acid suction: use the liquid-dispersing part 7 in step 3 to suck out the excess electrolyte in the battery, and...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is:

[0043] The concentration of the electrolyte in step 1 is 1.3g / cm 3 , the temperature is 25°C.

[0044] In step 3, the stirring speed of the electrolyte solution is 150 r / min.

[0045] The pumping pressure of the vacuum pump 2 in step 4 is 80MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com