Water sample pretreatment method and pretreatment system

A technology for pretreatment and water sampling, applied in the field of water treatment, can solve problems such as inconvenient operation of on-site maintenance personnel, and achieve the effect of improving service life, reducing maintenance costs, and meeting the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

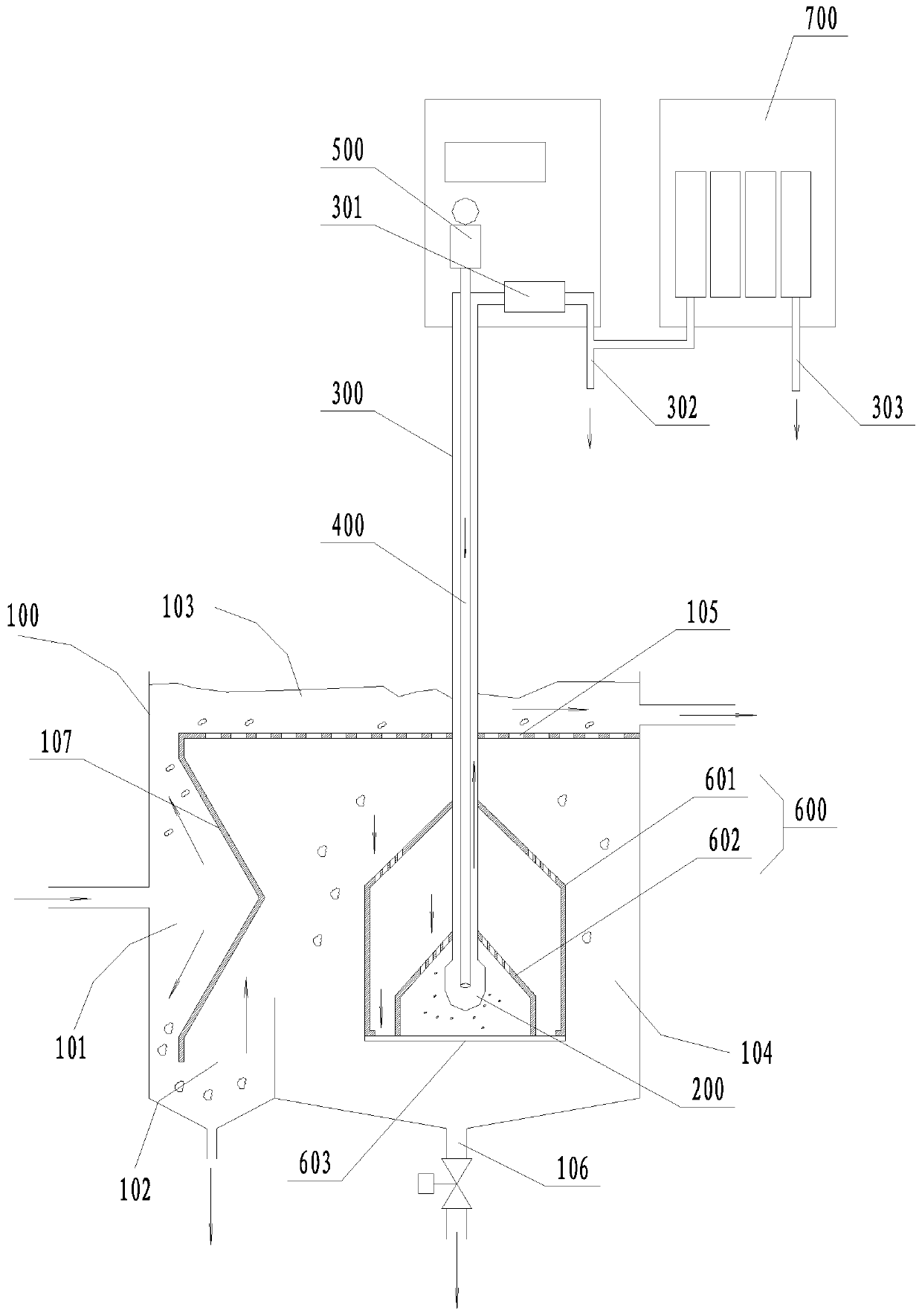

[0056] A water sample pretreatment method, comprising the following steps:

[0057] A. Removal of Particulate Matter

[0058]a1. Lead the water samples in the pipeline online, and reduce the flow rate of the water body to stratify the water body. The settleable particles in the water body will sink and be discharged, and the floatable particles in the water body will float up and be discharged with the continuous entry of the water body;

[0059] a2. The suspended particles contained in the water body are filtered through the external light metal filter membrane tube;

[0060] B. After the particulate matter in the water body is removed, part of it will be taken as a water sample and sent to the water quality analyzer for detection; the other part will enter advanced treatment;

[0061] C. Pure water is obtained after advanced treatment, which is used for on-site preparation of reagents;

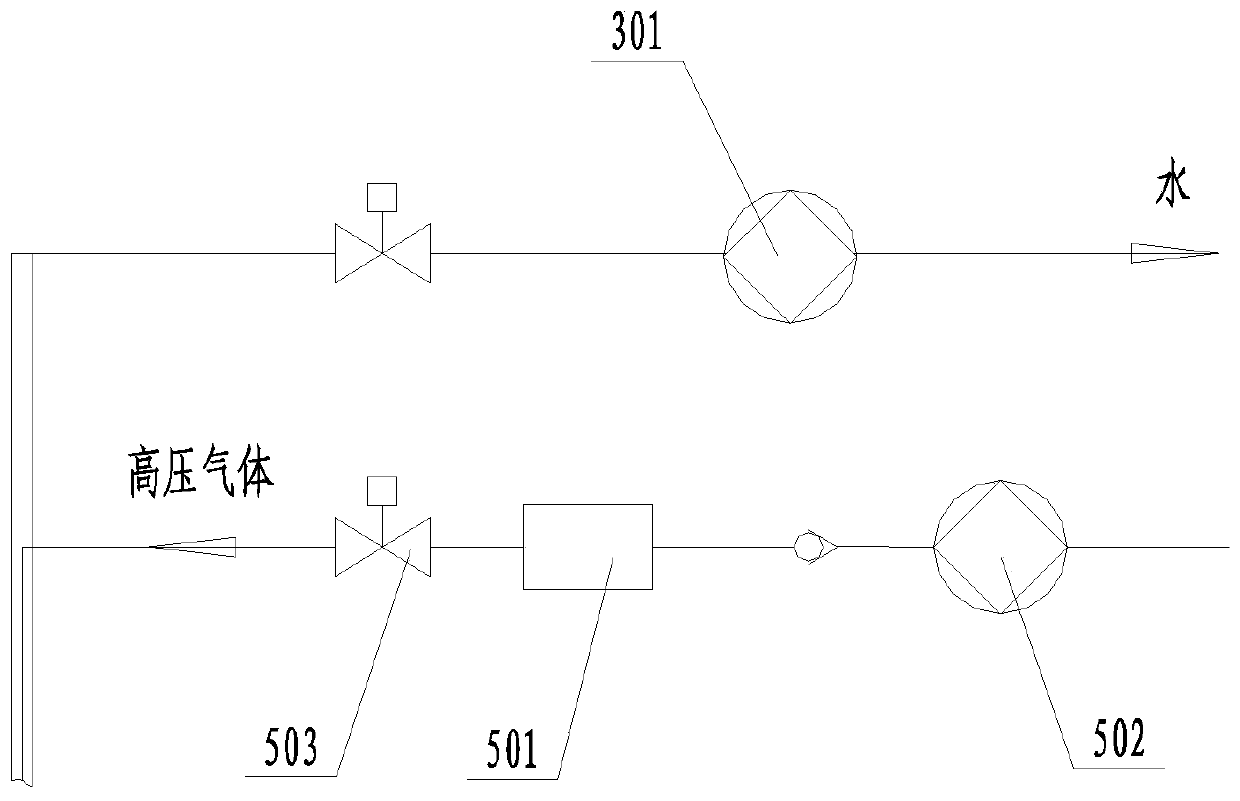

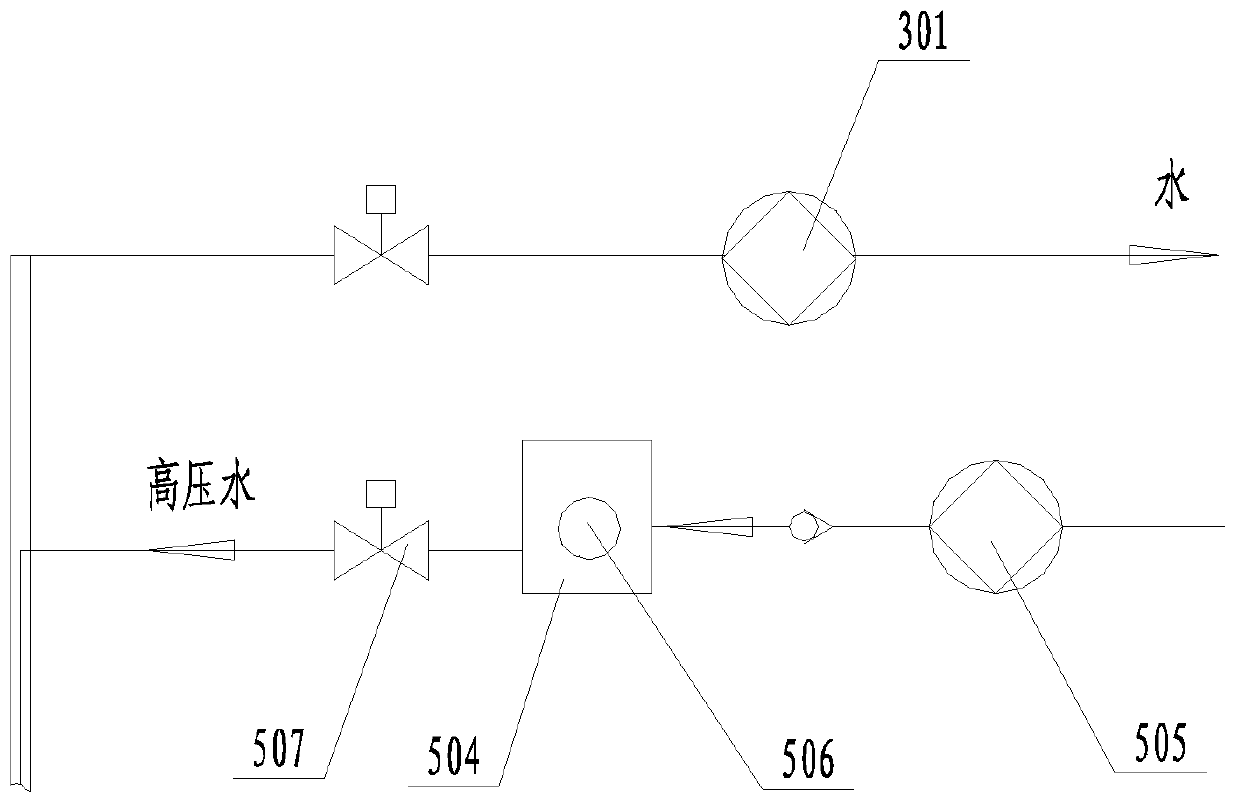

[0062] D. System maintenance, reverse flushing of the metal filter membrane tube with ...

Embodiment 2

[0080] Based on the first embodiment, the advanced treatment is the same as the advanced treatment of water in the prior art, and can be selected and combined according to the pollutant components contained in the water body. Advanced processing can include:

[0081] c1. Ultraviolet radiation to inactivate bacteria. Ultraviolet irradiation has been widely used in water treatment. The 254nm ultraviolet rays emitted by low-pressure mercury lamps are an effective sterilization method, because DNA and proteins in bacteria will absorb ultraviolet rays and cause death.

[0082] c2. Use the ultrafiltration membrane to perform deep filtration treatment on the water body to remove colloids, suspended solids, particulate matter, etc. in the water body. Ultrafiltration (UF) is a filtration term referring to a filter that removes particles such as protein-sized particles. The membrane pore size is usually between 1-50nm. The ultrafiltration membrane with hollow fiber structure usually h...

Embodiment 3

[0088] Based on the first embodiment, before step a2, a primary filtration of the suspended particulates contained in the water body is also included to remove large suspended particulates.

[0089] The water sample filtering device also includes a filter chamber 600, which is closed and sleeved outside the external light-type metal filter membrane tube 200 for preliminary filtration of suspended particles, and can protect the external light-type metal filter membrane tube 200. The filter chamber 600 There is a one-way baffle 603 that can be opened when the backwash mechanism 500 is working.

[0090] like Figure 4 As shown, one end of the one-way water baffle 603 is hinged to the warehouse body, and a tension spring 604 is fixed between the inner side of the water baffle 603 and the inner wall of the warehouse. When the backwash mechanism 500 works, the high-pressure gas Or the liquid overcomes the tension of the circlip 604 and pushes the one-way water baffle 603 to open ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com