A Helicopter Maintenance Method Based on Two-level Maintenance System

A helicopter and system technology, applied in aircraft maintenance, mechanical bearing testing, instruments, etc., to achieve the effect of improving usability, reducing direct maintenance costs, and increasing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

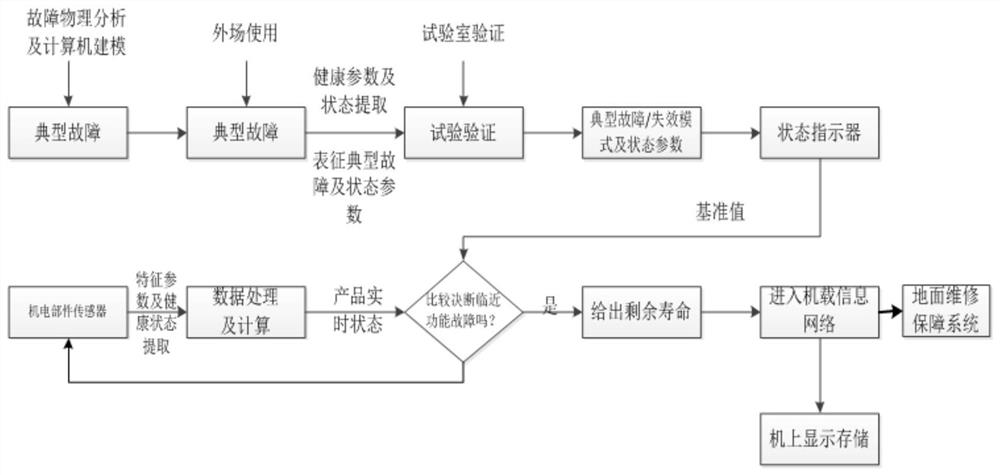

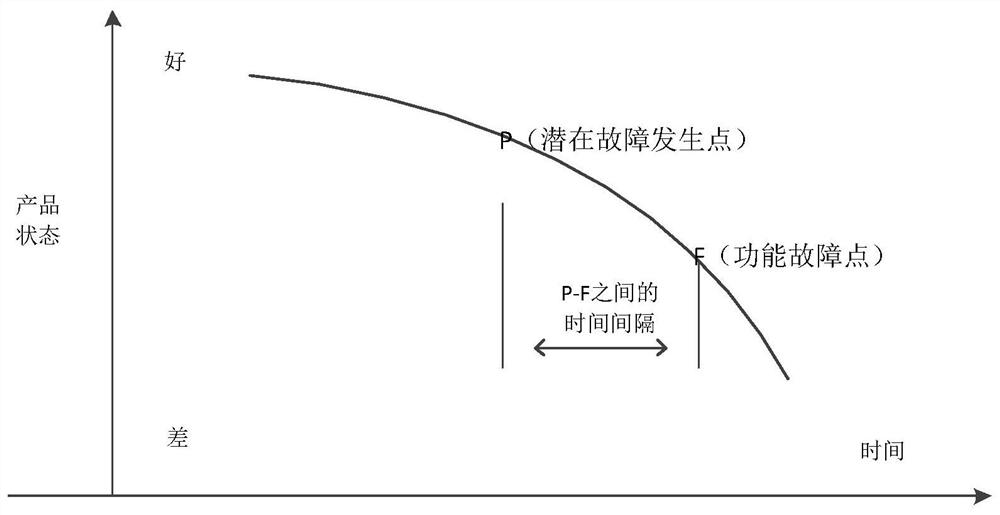

Method used

Image

Examples

specific example

[0050] A specific example of the present invention is as follows:

[0051] Design of helicopter on-board lubricating oil status monitoring system:

[0052]In the past, the lubricating oil samples taken out of the machine at regular intervals were transported to the base lubricating oil analysis laboratory for analysis and transformed into online real-time monitoring, so as to realize the condition-based maintenance method. That is, by monitoring the use status of the lubricating oil on the aircraft, it is determined whether the contamination of the lubricating oil system is approaching its service life, which eliminates the time for sending the lubricating oil sample for inspection and the subsequent cleaning and replacement of the lubricating oil, which not only improves the use of the helicopter availability, and reduced maintenance support time and costs.

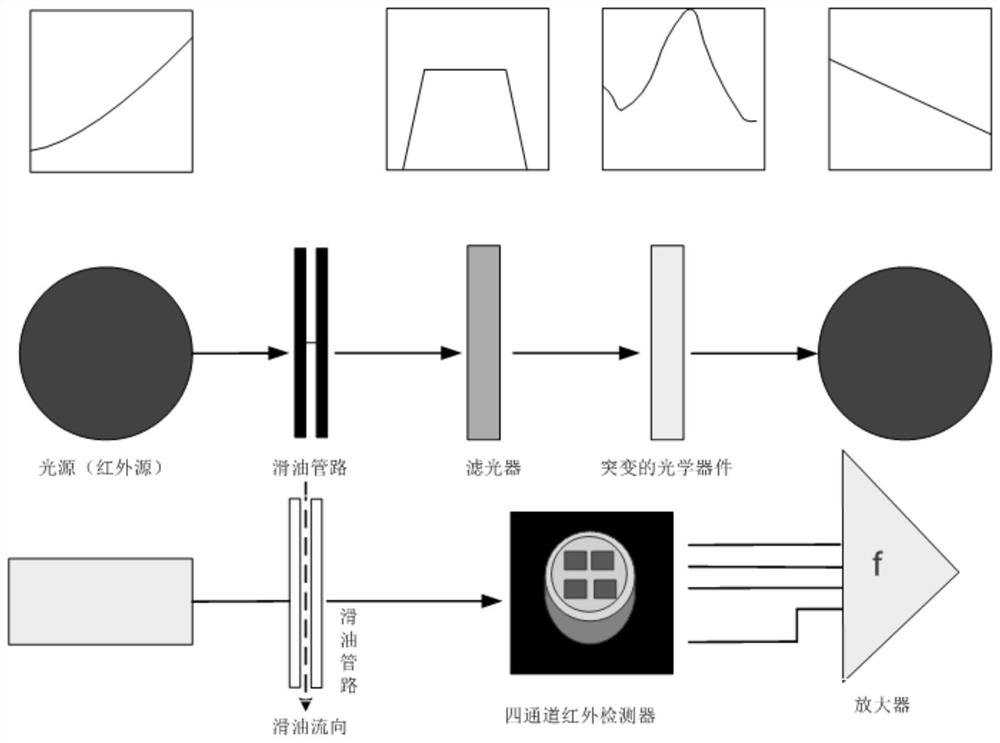

[0053] This online monitoring system is also composed of a status indicator and a lubricating oil status detection an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com