Three-edge-sealing bag-making device for food packaging

A bag-making device and food packaging technology, applied in packaging, multiple packages, transportation and packaging, etc., can solve the problems of complex bag-making devices and cumbersome installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

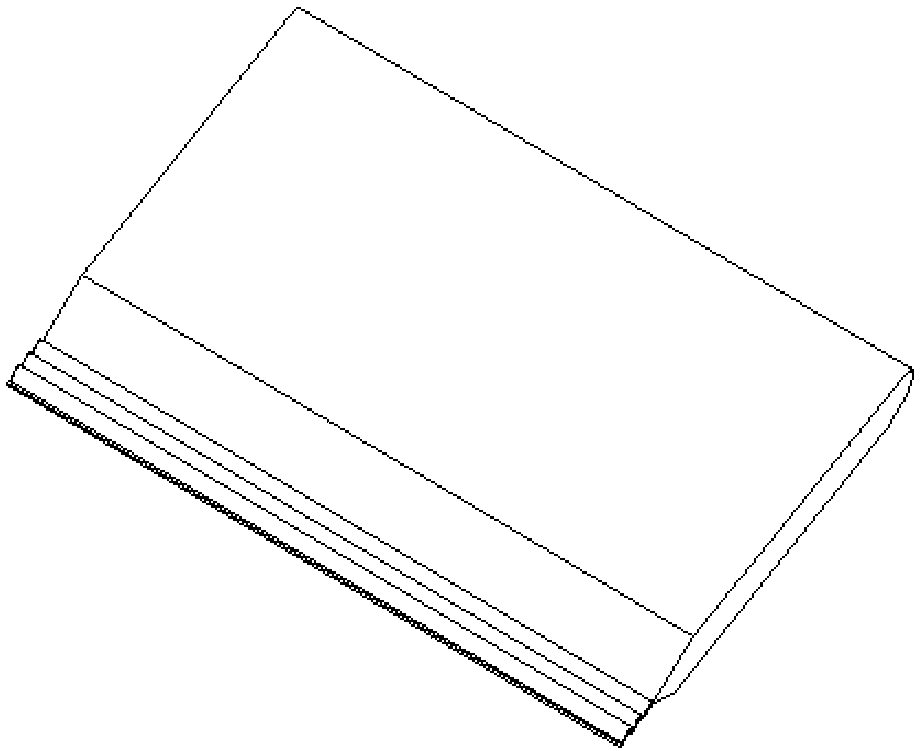

[0022] A three-side sealing bag-making device for food packaging, which is located between the conveyor belt 6 and the middle sealing and film-drawing station, and includes a horizontally arranged bag-making machine forming tube 1 and a bag-making machine garment welded to the bag-making machine forming tube 1 Collar 2 and the bag maker fixing plate 3 that fixes the bag maker collar 2, wherein:

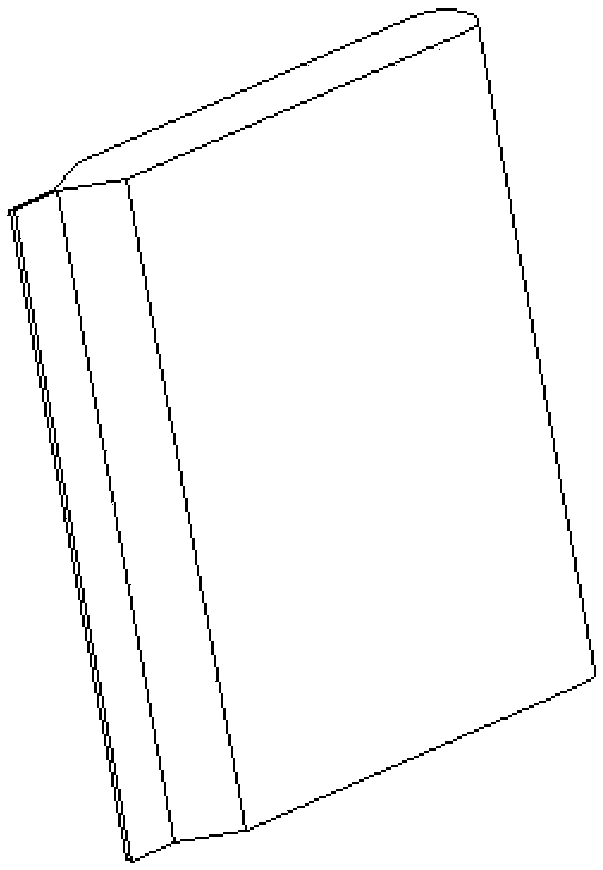

[0023] The forming tube 1 of the bag making device is a grooved tube with a side opening, one end of the forming tube of the bag making device corresponds to the film pulling roller group 41 vertically arranged in the center sealing film pulling station, and the other end is an oblique inlet 11 ;

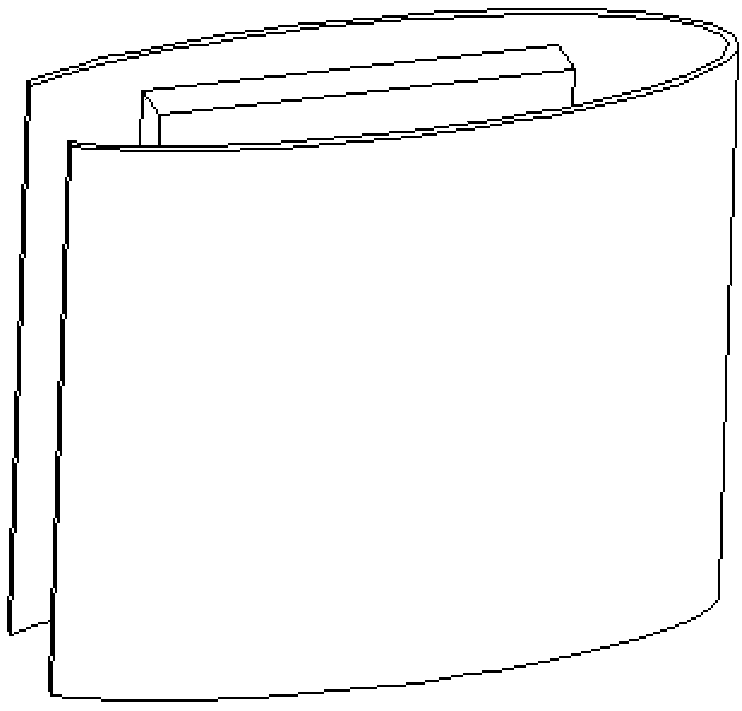

[0024] The bag maker collar 2 is bent from a flat plate 5 with a triangular opening 51 on one side, and one end forms an oblique outlet to facilitate welding with the upper oblique inlet 11 of the bag maker forming tube 1, while the other end is connected to the oblique inlet 11 of the bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com