High polymer material conveying system

A polymer material and conveying system technology, applied in the field of polymer material conveying system, can solve the problems of natural fiber slipping, natural fiber accumulation, unfavorable natural fiber transportation, etc., and achieve the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

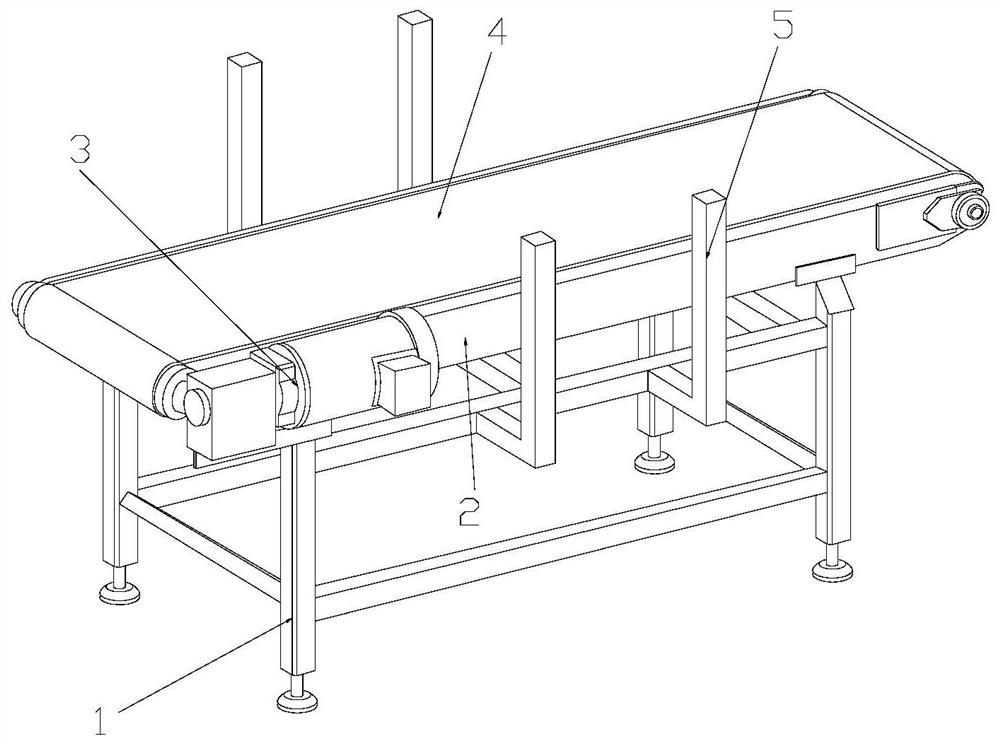

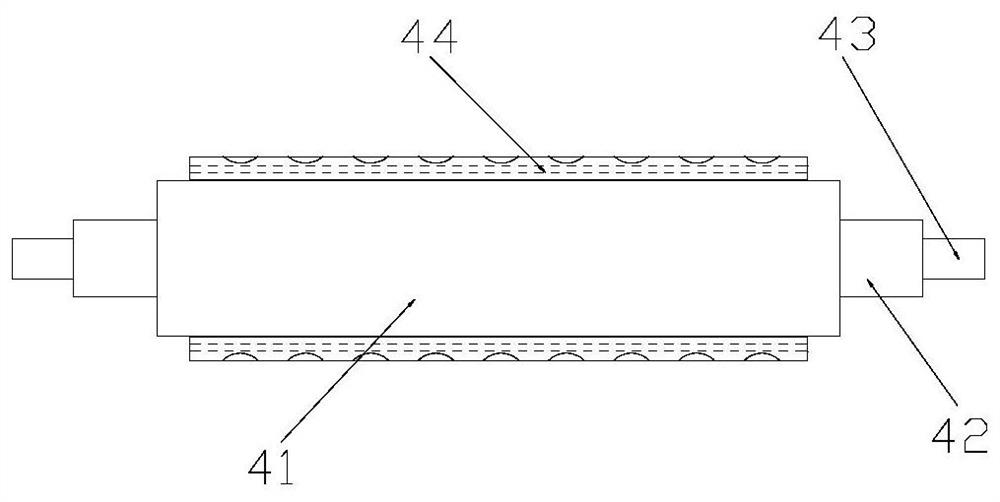

[0029] Its structure includes a frame 1, a side frame 2, a motor 3, a conveying structure 4, and a protective frame 5. The side frame 2 is horizontally installed on the upper end of the frame 1 and welded, and the motor 3 is fixed on the side end of the side frame 2 and Through bolt connection, the conveying structure 4 is installed between the side frames 2 and mechanically connected with the motor 3, and the protective frame 5 is welded to the side end of the frame 1 and is located outside the side frame 2; the conveying structure 4 includes driving rollers 41. The connecting shaft 42, the linkage shaft 43, and the conveying plate 44, the connecting shaft 42 is installed on the side end of the driving roller 41 and is located on the same axis, the linkage shaft 43 is fixed on the outside of the connecting shaft 42 and mechanically connected with the moto...

Embodiment 2

[0035] Example 2: Please refer to image 3 , Figure 7-Figure 8 , the specific embodiments of the present invention are as follows:

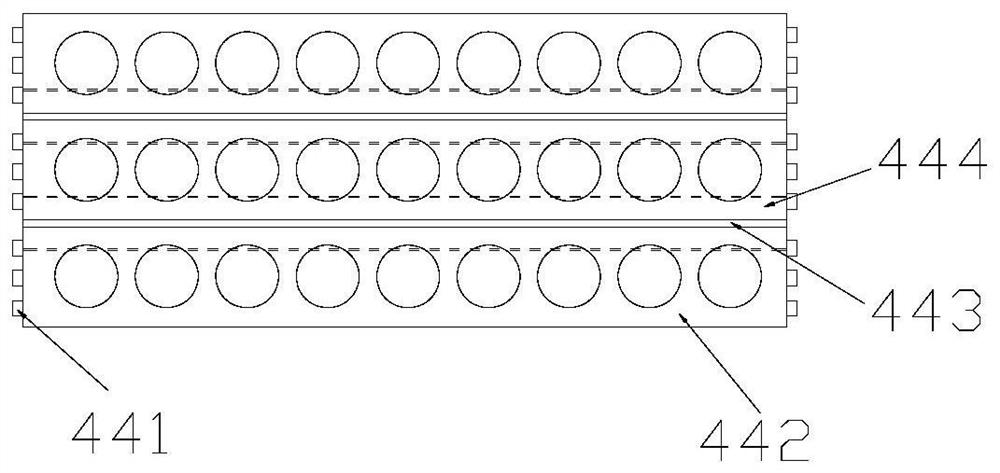

[0036] The conveying plate 44 includes a transmission tooth 441, a linkage plate 442, a spacer groove 443, and a movable structure 444. The transmission tooth 441 is installed on the inner side of the linkage plate 442 and is an integrated structure, and the spacer groove 443 is arranged on the linkage plate 442. The movable structure 444 is hinged between the linkage plates 442 and located at the lower end of the interval slot 443 .

[0037] refer to Figure 7The movable structure 444 includes a fixed seat 44a, a guide groove 44b, a movable plate 44c, a support 44d, and a clamping structure 44e. The guide groove 44b is arranged inside the fixed seat 44a and is an integrated structure. The movable plate 44c Installed on the outside of the fixed seat 44a and movably connected with the guide groove 44b, the support 44d is vertically installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com