Laser camouflage coating and preparation method thereof

A stealth coating and laser technology, applied in camouflage coatings, radiation-absorbing coatings, coatings, etc., can solve problems such as ineffective compatibility with optical camouflage performance, achieve effective anti-laser reconnaissance guidance camouflage performance, easy to use, excellent durability The effect of environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

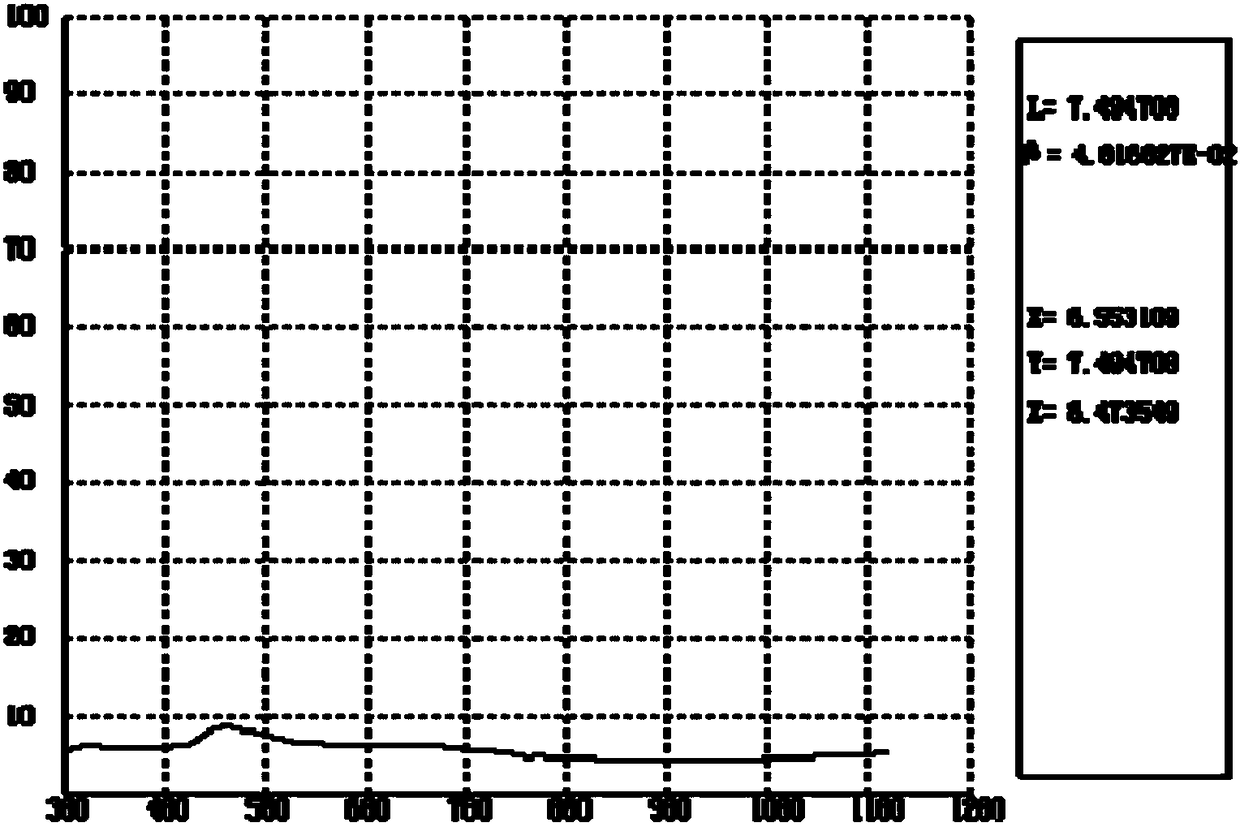

Embodiment 1

[0027] DG0730 dark green laser stealth paint, including the following components by weight: 55 parts of hydroxyl acrylic resin, 15 parts of laser absorbing pigment, 11 parts of chromium oxide green, 0.2 part of titanium dioxide, 8 parts of iron oxide yellow, 3 parts of iron oxide red, 4 parts of iron oxide black, 0.1 part of purple powder, 0.5 parts of BYK defoamer, 1 part of BYK dispersant, 0.7 parts of Hemings anti-settling agent, 4 parts of TS100 matting powder, 10 parts of composite solvent and 10 parts of curing agent.

[0028] Wherein, the composite solvent is formed by mixing xylene, butyl acetate and PMA in a volume ratio of 6:3:1.

[0029] The preparation method of the above-mentioned DG0730 dark green laser stealth coating comprises the following steps: dissolving the BYK dispersant in a composite solvent, and then adding toning pigments (chrome oxide green, titanium dioxide, iron oxide yellow, iron oxide red, iron oxide black, Purple powder), laser absorbing pigment...

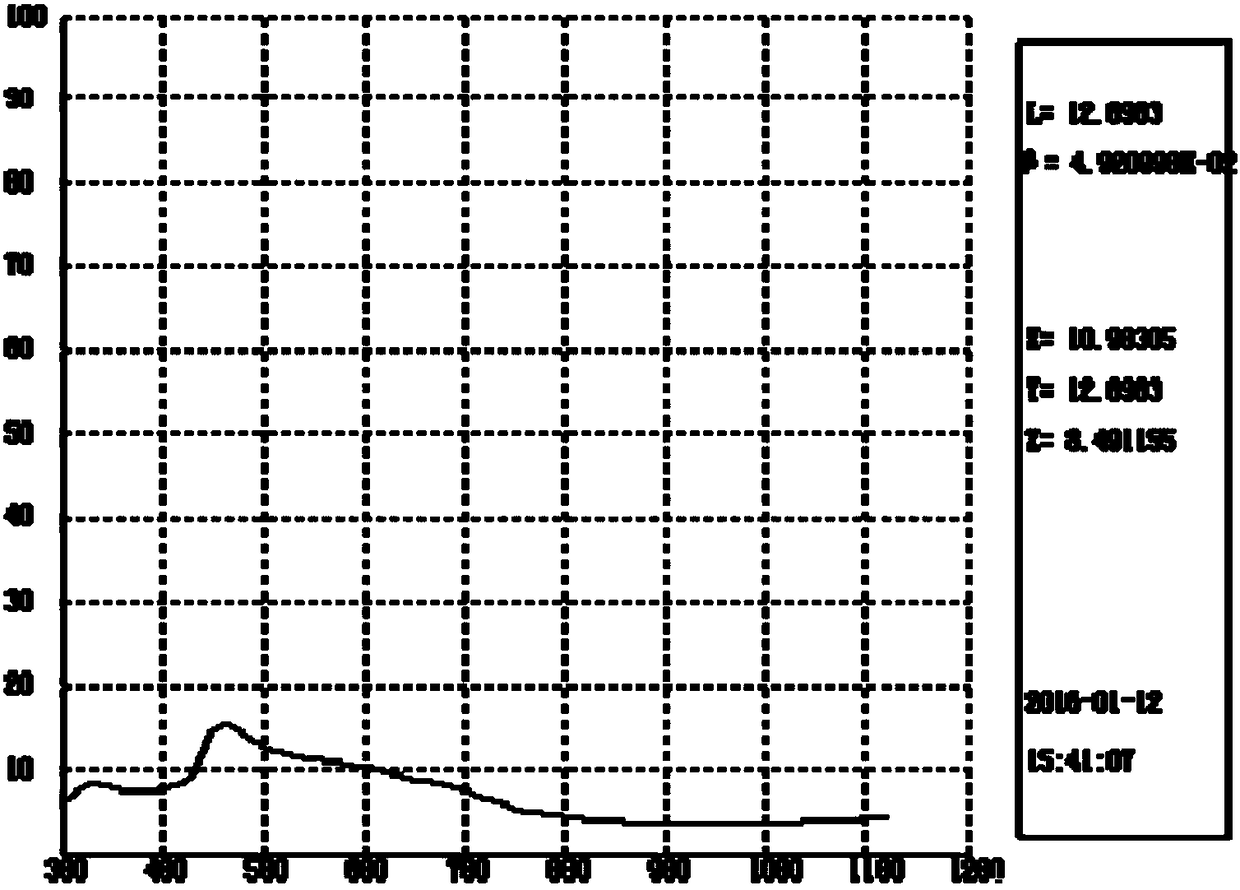

Embodiment 2

[0031] YG1247 yellow-green laser stealth paint, including the following components by weight: 48 parts of hydroxyacrylic resin, 16 parts of laser absorbing pigment, 15 parts of chromium oxide green, 1 part of titanium dioxide, 4 parts of iron oxide yellow, 0.2 part of iron oxide red, 0.2 parts of iron oxide black, 0.1 parts of purple powder, 0.5 parts of BYK defoamer, 1 part of BYK dispersant, 0.5 parts of Hemings anti-settling agent, 3 parts of TS100 matting powder, 10 parts of composite solvent and 8 parts of curing agent.

[0032] Wherein, the composite solvent is formed by mixing xylene, butyl acetate and PMA in a volume ratio of 6:3:1.

[0033] The preparation method of the above-mentioned YG1247 yellow-green laser stealth coating comprises the following steps: dissolving the BYK dispersant in a composite solvent, and then adding toning pigments (chrome oxide green, titanium dioxide, iron oxide yellow, iron oxide red, iron oxide black, Purple powder), laser absorbing pigm...

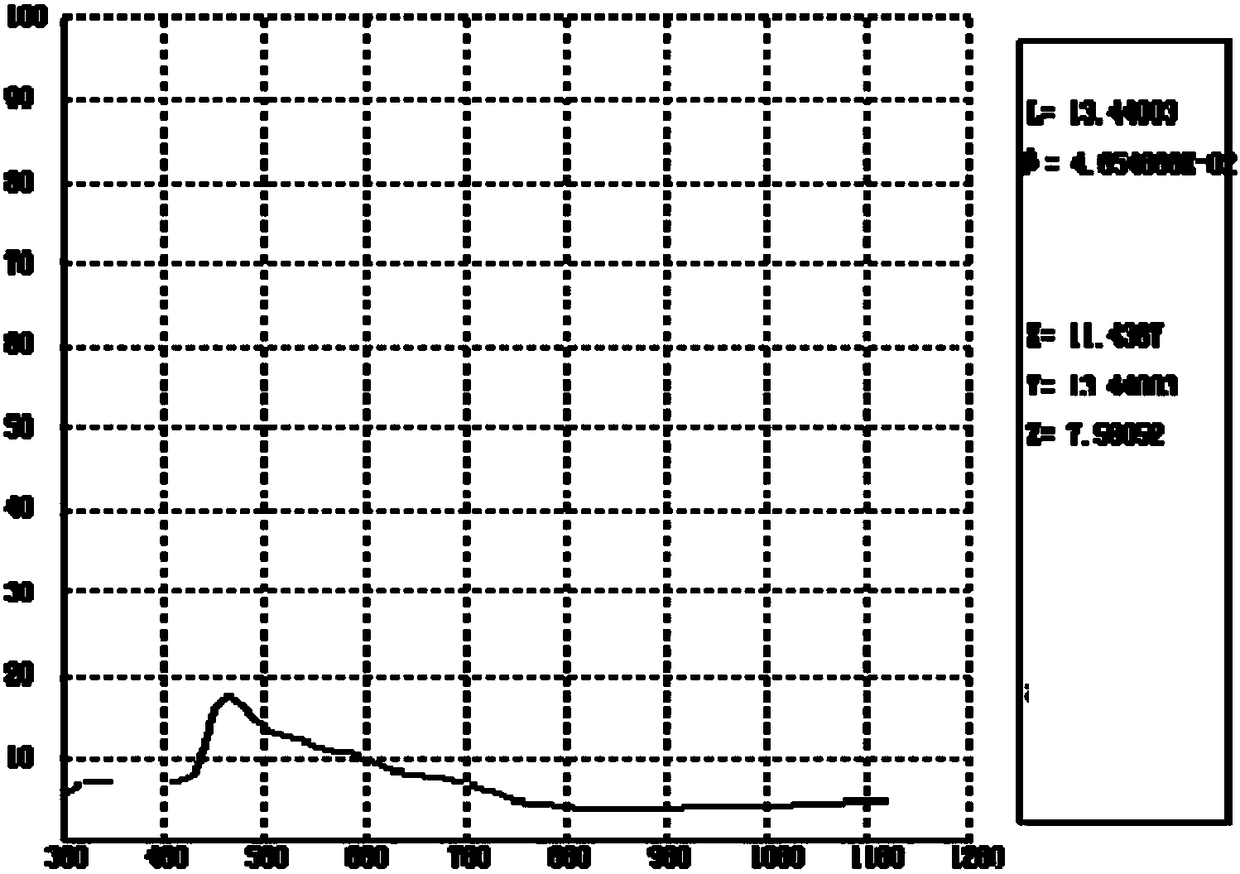

Embodiment 3

[0035] EG1456 emerald green laser stealth paint, including the following components by weight: 50 parts of hydroxyl acrylic resin, 20 parts of laser absorbing pigments, 8.5 parts of chromium oxide green, 1.6 parts of titanium dioxide, 8 parts of iron oxide yellow, 0.3 parts of iron oxide red, 0.1 parts of purple powder, 0.5 parts of BYK defoamer, 1 part of BYK dispersant, 0.5 parts of Hemings anti-settling agent, 4 parts of TS100 matting powder, 10 parts of composite solvent and 9 parts of curing agent.

[0036] Wherein, the composite solvent is formed by mixing xylene, butyl acetate and PMA in a volume ratio of 6:3:1.

[0037] The preparation method of the above-mentioned EG1456 emerald green laser stealth coating comprises the following steps: dissolving the BYK dispersant in a composite solvent, adding toning pigments (chrome oxide green, titanium dioxide, iron oxide yellow, iron oxide red, purple powder), Laser absorbing pigment and 1 / 2 weight of hydroxyacrylic resin, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com