Positioning tool for engine inspection

A technology for positioning tooling and engines, which is applied in the direction of engine testing, measuring devices, and testing of machine/structural components, etc. It can solve the problems of difficult engine operation, reduce manual labor, facilitate operation, and save power resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

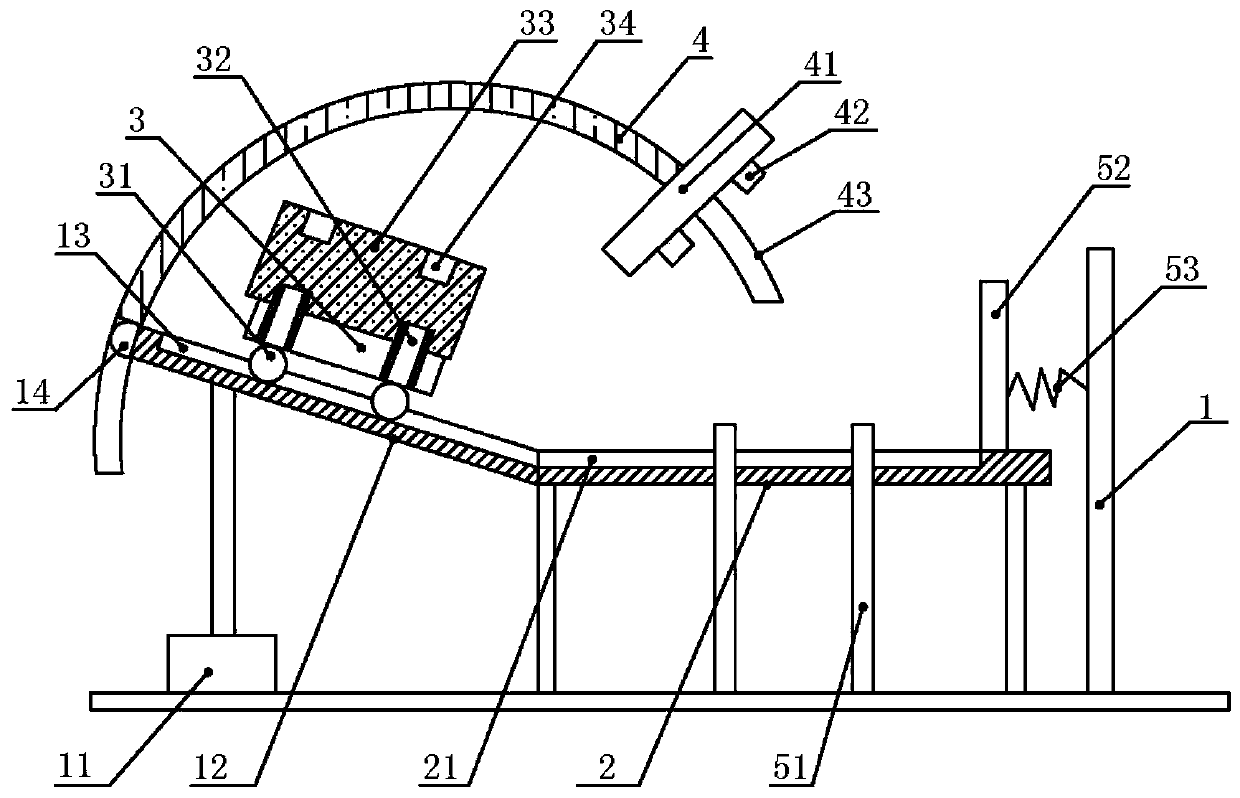

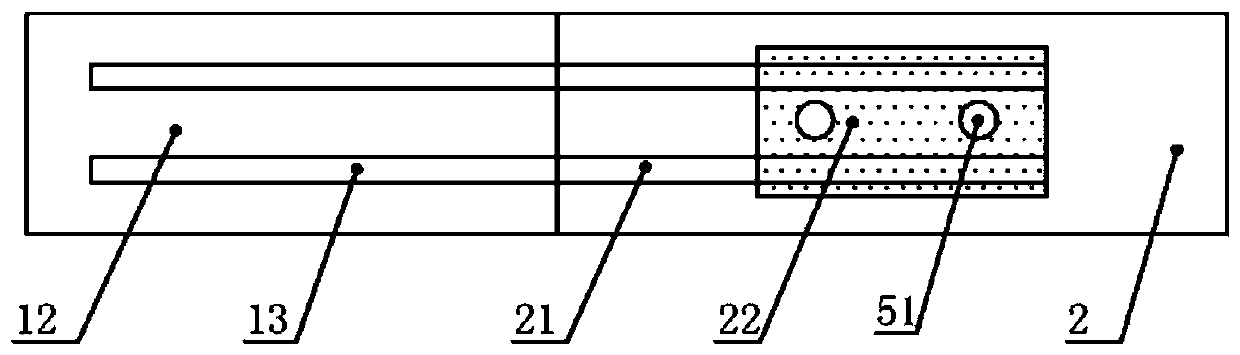

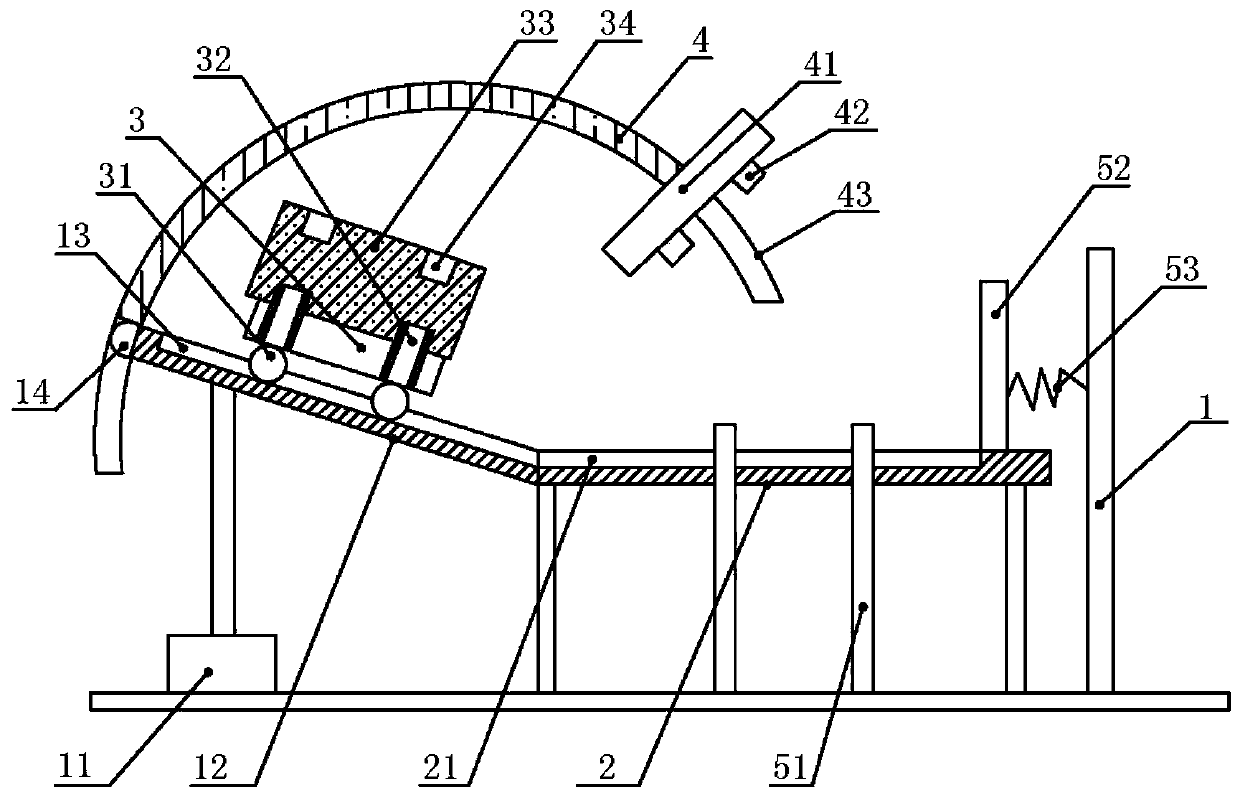

[0024] The reference signs in the accompanying drawings of the description include: frame 1, cylinder 11, slide table 12, second slide rail 13, ball 14, support table 2, first slide rail 21, turning plate 22, loading cart 3, rollers 31, positioning pipe 32, motor 33, mounting hole 34, pole 4, pressing plate 41, positioning pin 42, slideway 43, positioning column 51, baffle plate 52, spring 53.

[0025] Such as figure 1 As shown, the positioning tool for engine detection of the present invention includes a frame 1, and a supporting platform 2 is installed on the frame 1, such as figure 2 As shown, the support platform 2 is provided with a parallel first slide rail 21, the middle part of the support platform 2 is provided with an opening, and a flap 22 is installed at the opening, and the edge of the flap 22 is connected with the edge of the opening by glue. A first slide rail 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com