Line maintenance bearing support capable of stable positioning

A line maintenance and support frame technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems such as the internal mechanism is not actually separated, the knife switch with load, and the length of the electroscope is short, so as to eliminate potential safety hazards, prevent slippage, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

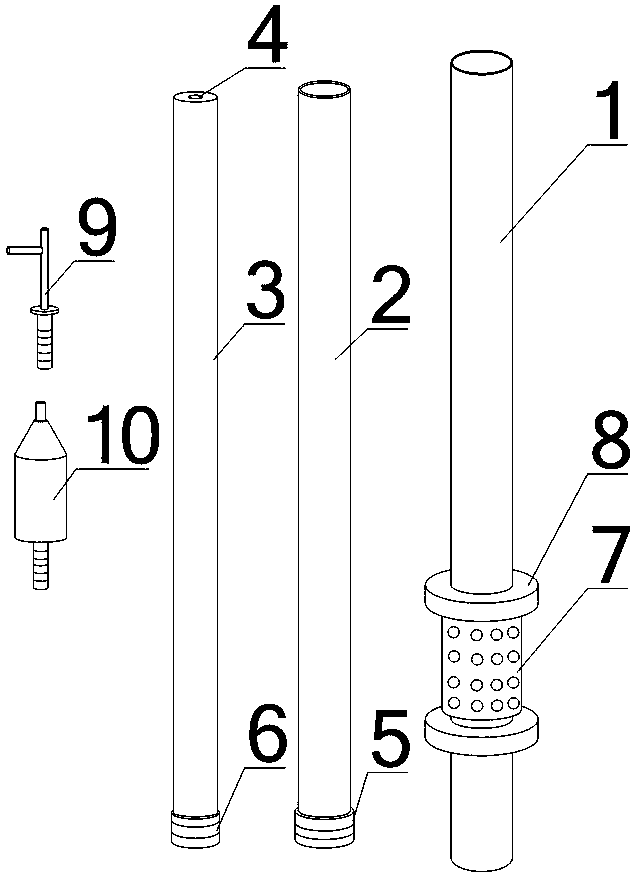

[0014] Such as figure 1 As shown, a support frame for line maintenance with stable positioning includes a working head 9 of a gram bar, a test head 10 and a telescopic piece, wherein the telescopic piece includes a bottom casing 1, an extension pipe 2 and a positioning rod 3. When setting, it should be ensured that the bottom casing 1, the extension pipe 2 and the positioning rod 3 all have a certain length. Both the upper ends of the bottom casing 1 and the extension pipe 2 are formed with internal threads, and the lower end of the extension pipe 2 is connected with a first positioning thread head 5, and the first positioning thread head 5 is provided with an outer thread matching the internal thread at the upper end of the bottom casing 1. thread, the first positioning thread head 5 is connected to the upper end of the bottom casing 1 through thread matching, the lower end of the positioning rod 3 is connected to the second positioning thread head 6, and the second positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com