Cleaning device for inner walls of steel pipes

A cleaning device and a technology for the inner wall of a steel pipe, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effect of power source energy saving and high-quality cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

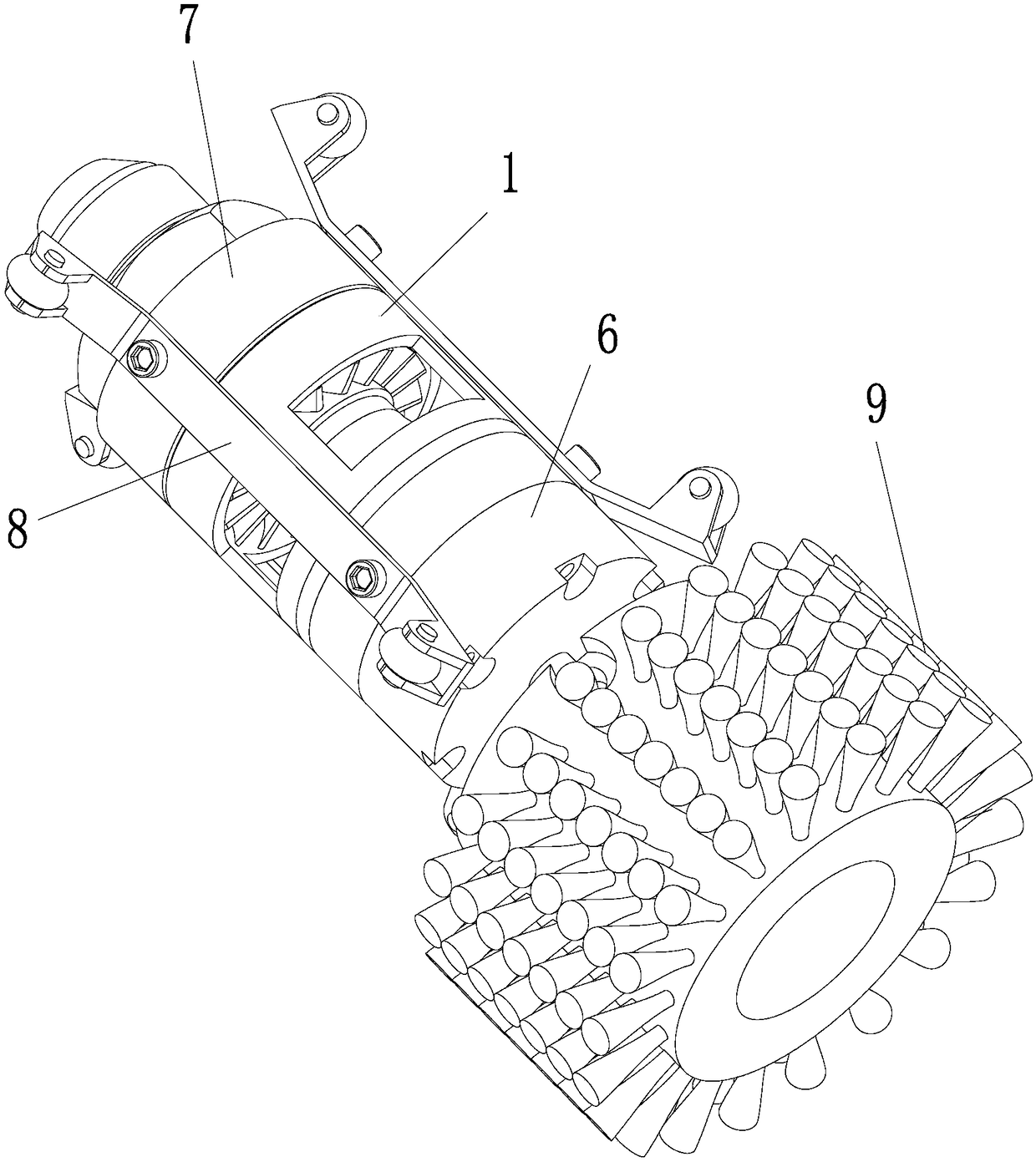

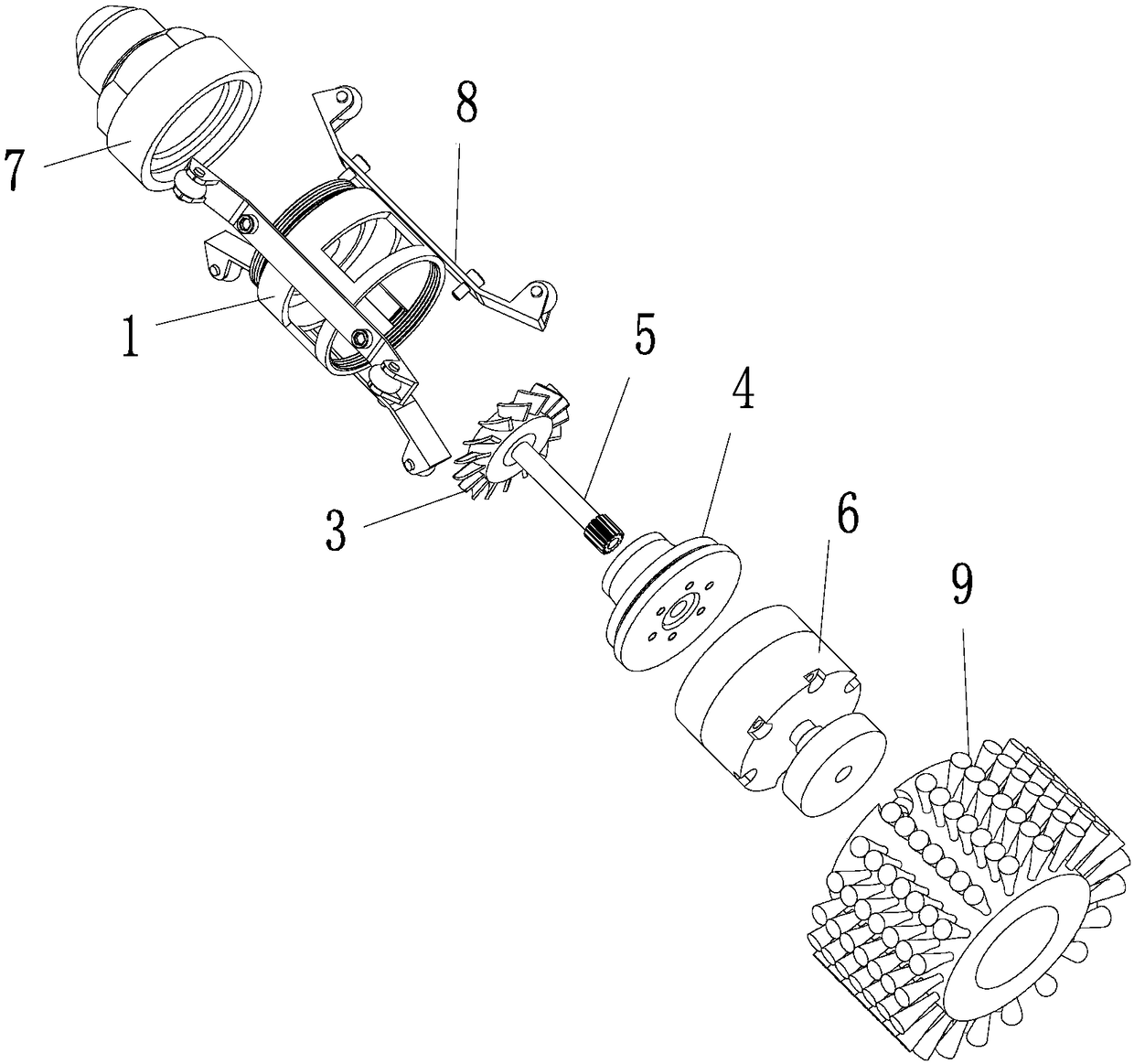

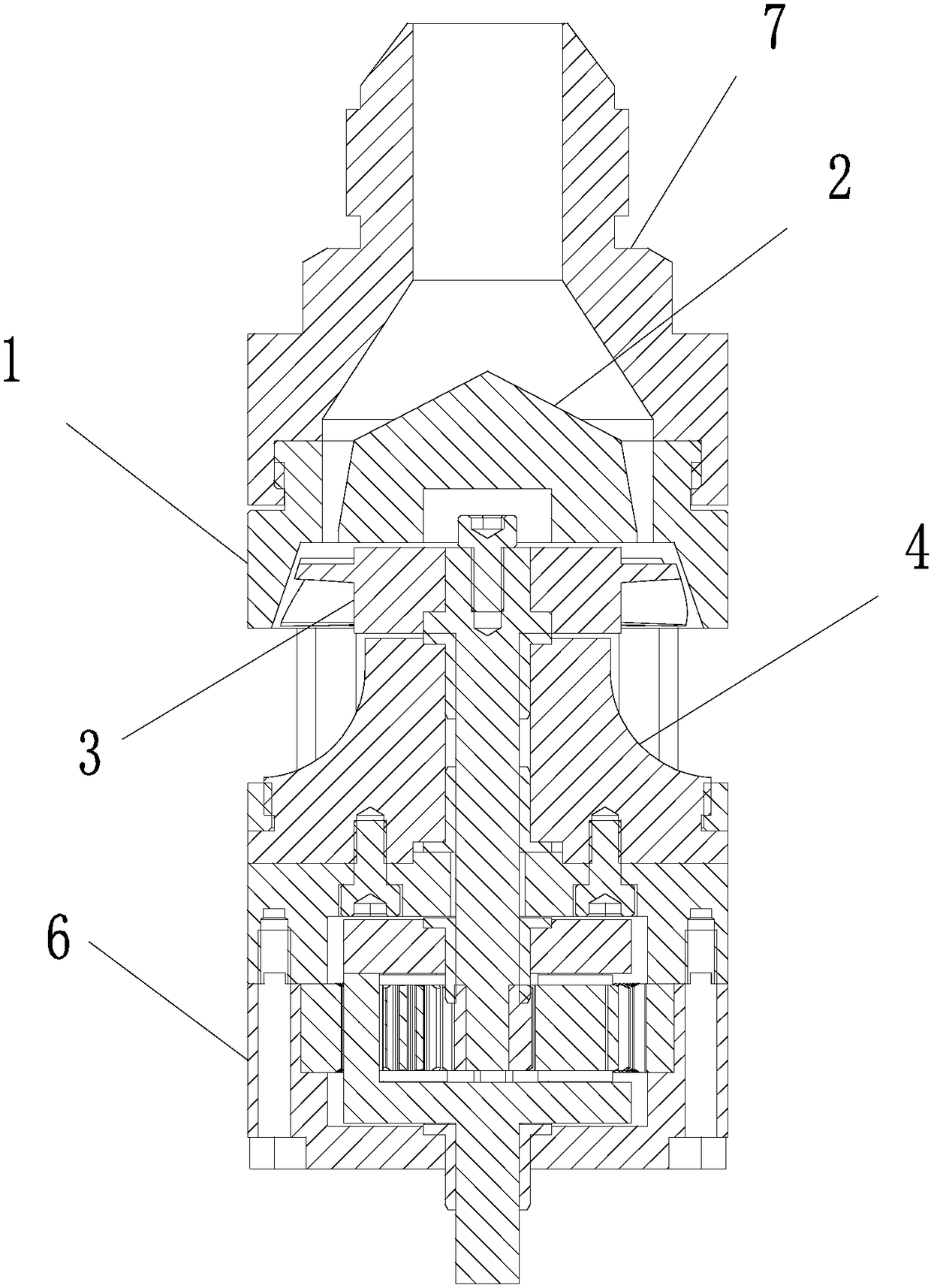

[0031] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0032] like Figure 1 to Figure 8 As shown, a cleaning device for the inner wall of a steel pipe includes a casing 1, and the casing 1 is sequentially provided with a first installation chamber, an impeller chamber 1B and a second installation chamber from top to bottom, and a shunt is fixedly arranged in the first installation chamber. Part 2, a water inlet ring cavity 1A is formed between the surroundings of the distribution part 2 and the inner wall of the first installation cavity, and the water inlet ring cavity 1A communicates with the impeller cavity 1B. The flow guide 4 is fixedly arranged at the lower end of the housing 1, the flow guide 4 is located in the second insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com