Forming die sleeve for super-hard grinding wheel, and die applying die sleeve

A mold sleeve and grinding wheel technology, which is applied in the field of forming mold sleeves for superhard grinding wheels, can solve the problems of shortened service life, increased mold loss, non-detachable and fixed mold sleeves or integrally arranged on the mold base, etc., so as to improve the utilization rate , Prolong the repair period, reduce the effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

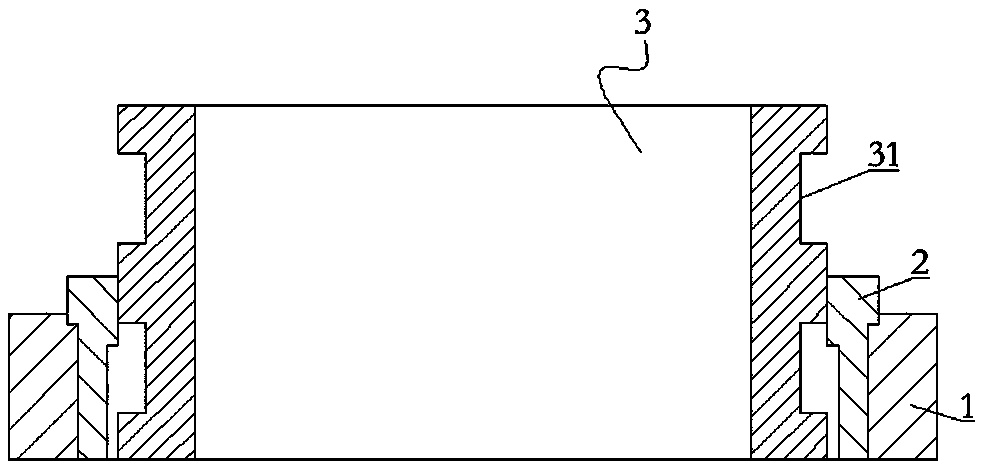

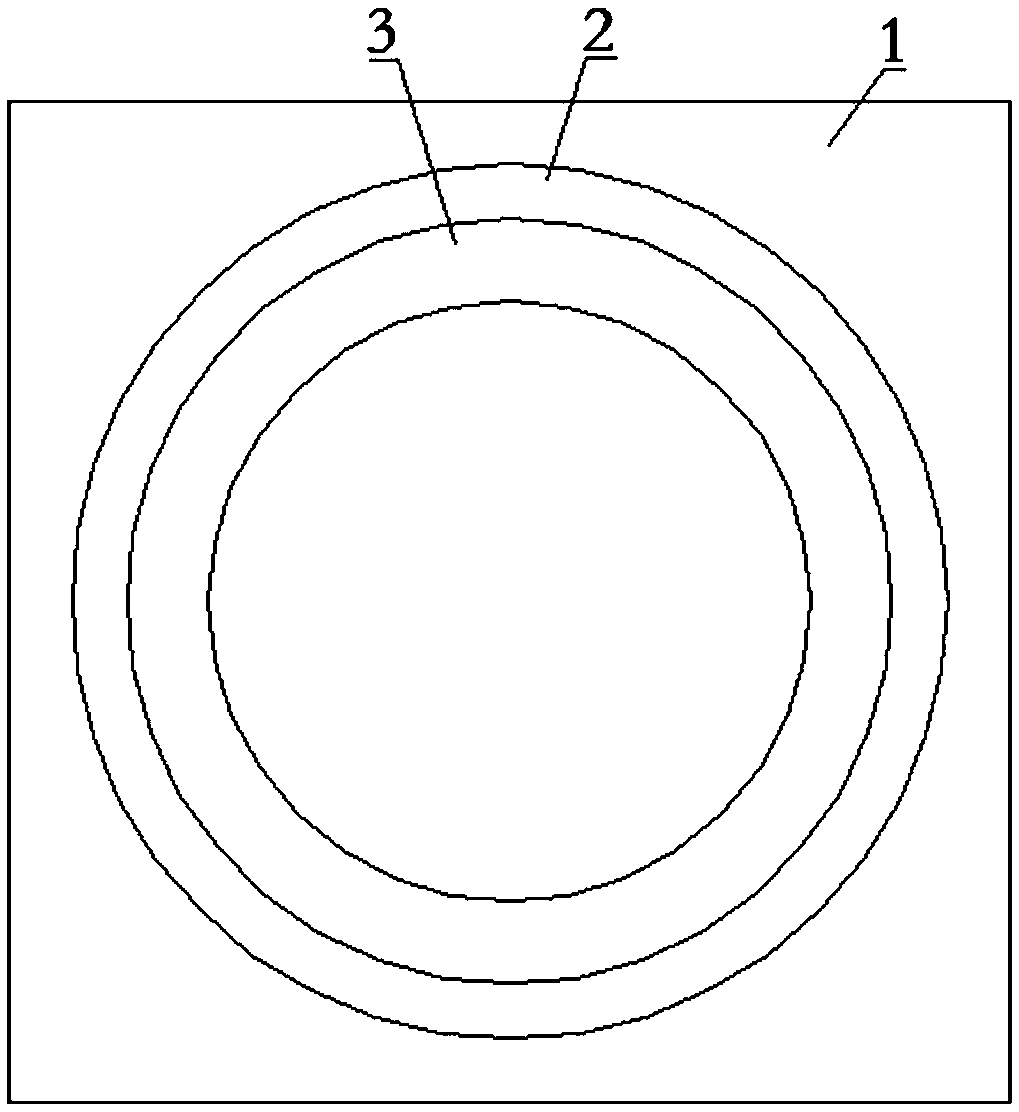

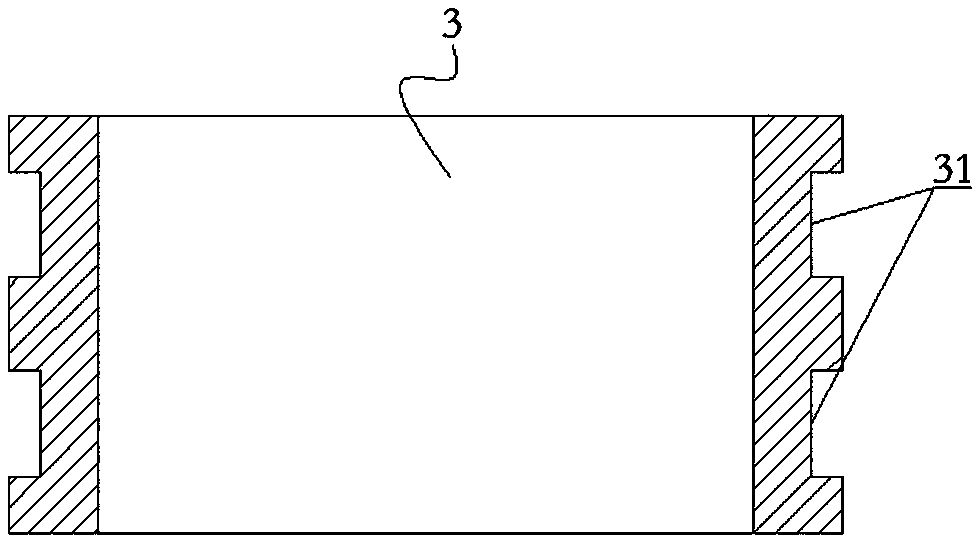

[0017] The embodiment of mold among the present invention: as figure 1 and figure 2 As shown, the mold is mainly composed of three parts: base 1, snap ring 2 and die sleeve 3, wherein base 1 is a square seat, and a circular assembly hole is opened in the center of base 1; snap ring 2 is a circular ring , the snap ring 2 is inserted into the assembly hole of the base 1 to form a square mold base with the base 1, and the outer peripheral surface of the snap ring 2 and the wall surface of the installation hole adopt a transition fit method, on the one hand, to ensure that the snap ring 2 can be easily taken out from the base 1. On the other hand, the reliable fixing of the snap ring 2 on the base 1 is ensured, and the inner hole of the snap ring 2 is a mounting hole for the mold sleeve 3 to be inserted into; image 3 As shown, the mold cover 3 is a circular sleeve structure, the mold cover 3 is detachably inserted into the snap ring 2, the lower end of the mold cover 3 sinks in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com