Automobile anti-collision beam with buffering effect

A buffering and anti-collision beam technology, applied in bumpers and other directions, can solve the problems of inability to protect the cross beams on both sides of the bottom of the car and the limited compressive capacity of the anti-collision beam, achieving high stability, good stability and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

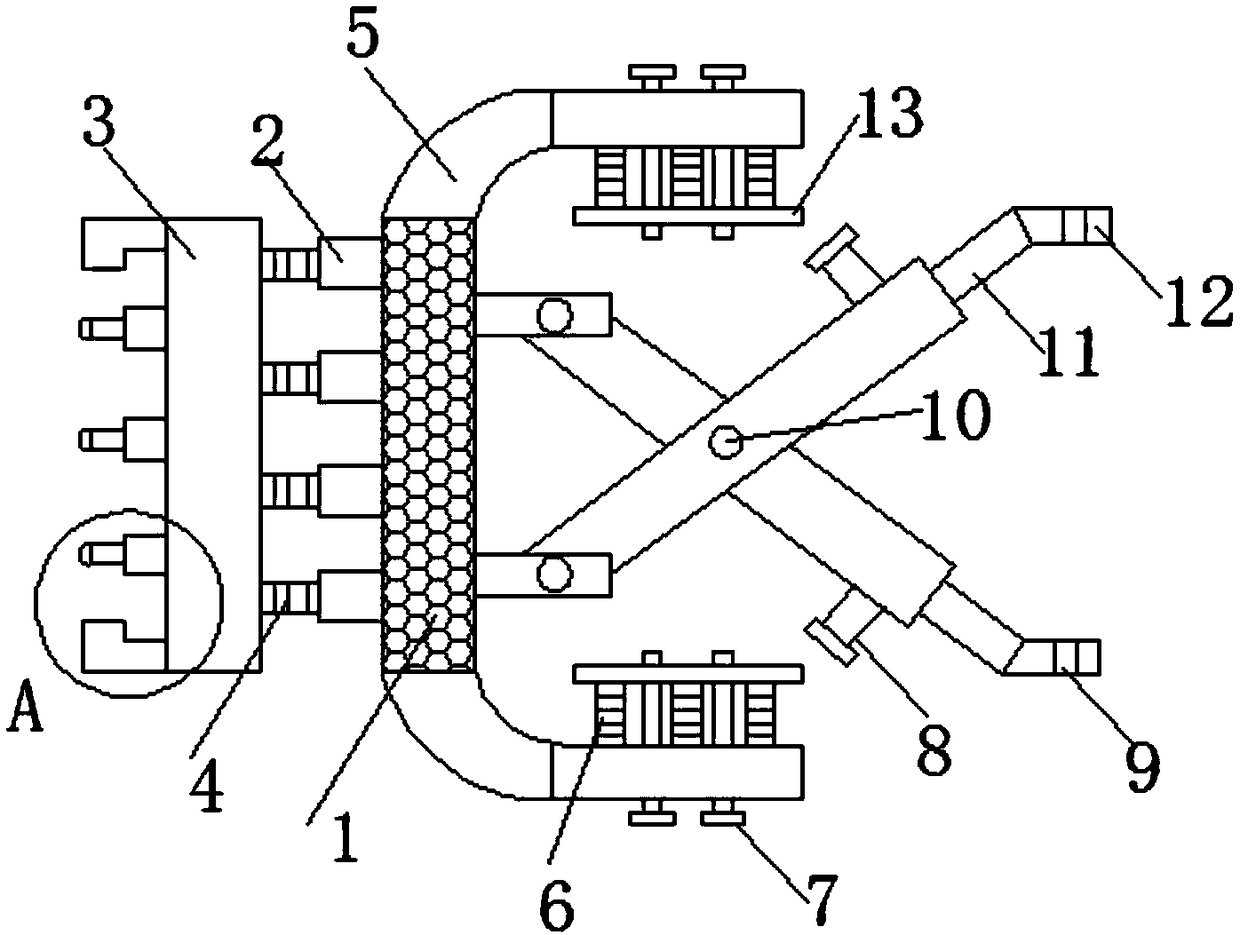

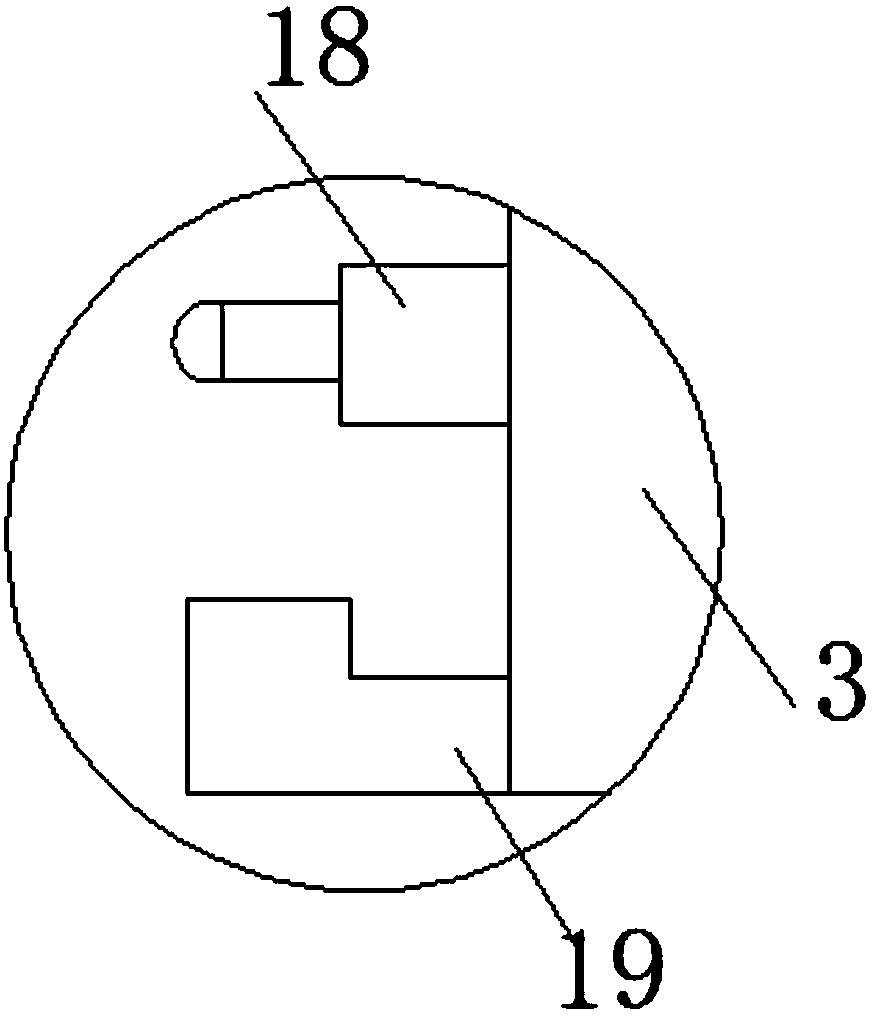

[0024] see Figure 1-4 As shown, an automobile anti-collision beam with buffering function includes a beam body 1, a transverse plate 3, a connecting head 5 and a telescopic column 11, and a transverse plate 3 is connected to one side of the beam body 1, and the transverse plate 3 is connected to the beam body 1. A number of first shock springs 4 are connected between them, a limit plate 19 is connected to both ends of one side of the horizontal plate 3, and a number of brackets 18 are connected to one side of the horizontal plate 3, and a second shock spring is installed inside the bracket 18. 14. One end of the bracket 18 is movably connected with a ball 20. The cross plate 3 can withstand the impact force of a part of the car. The second shock spring 14 and the first shock spring 4 between the cross plate 3 and the beam body 1 contract when under pressure. It acts as a buffer, reduces the harm caused by the impact, and protects the beam body 1 from damage. When the car is h...

Embodiment 2

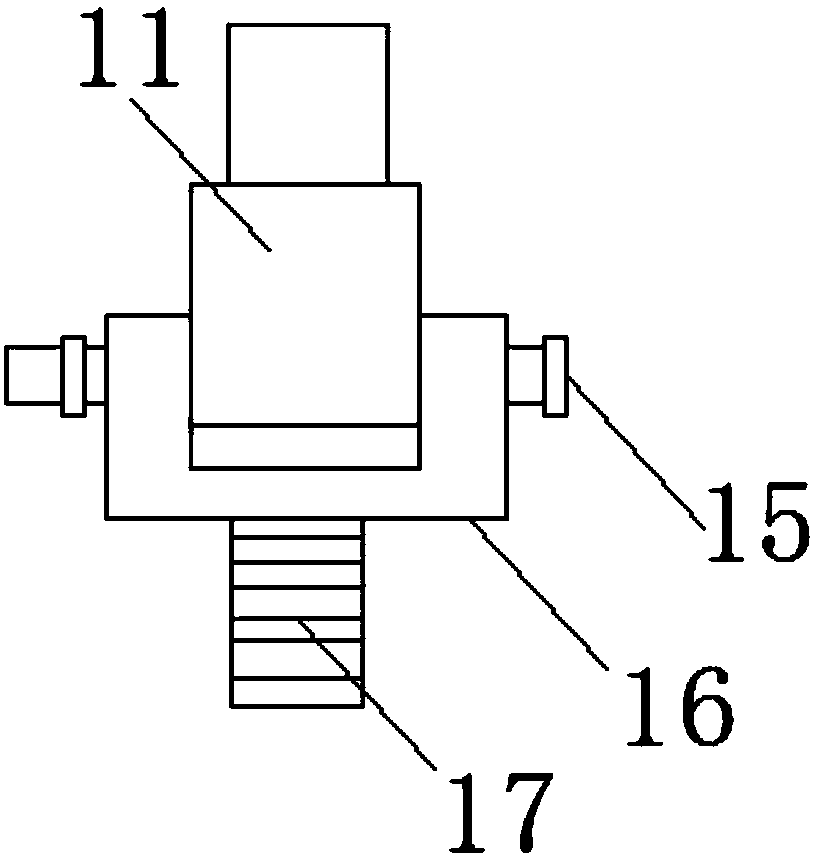

[0026] In addition, please Figure 1-4 As shown in the figure, the difference between it and the above-mentioned embodiment is that one end of the first shock absorbing spring 4 is connected with the spring seat 2, and the first shock absorbing spring 4 is sheathed inside the spring seat 2, and the first shock absorbing spring 4 can contract when compressed. Inside the spring seat 2, the first shock absorbing spring 4 is evenly stressed and not easily damaged, and has a longer service life. One end of the connecting head 5 is connected with a tightening bolt 7, and one end of the tightening bolt 7 vertically penetrates the connecting head 5 and the baffle 13, and the tightening bolt 7 penetrates the connecting head 5 and the baffle 13 to fix the connecting head 5 on the side of the beam, and The coil spring 6 is pressed between the baffle 13 and the connecting head 5 . The middle of the two telescopic columns 11 is connected with a fixing rod 10, and the middle of the two tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com